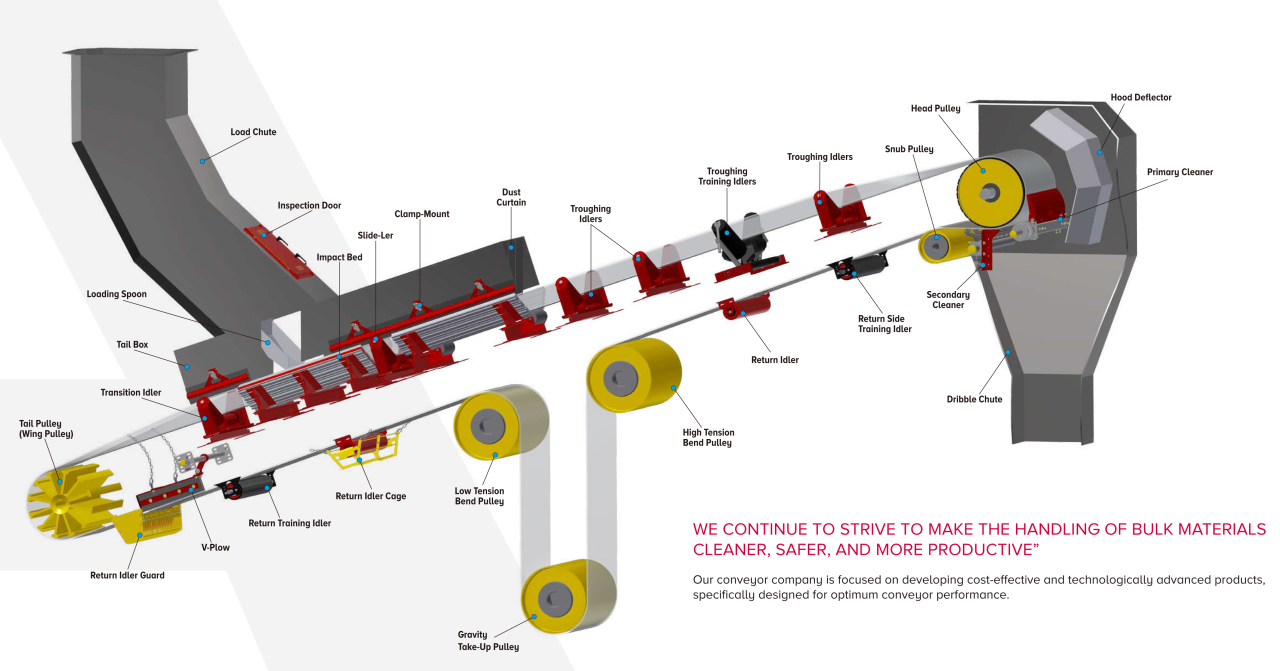

Mining belt conveyor is specialized equipment for material handling in mining operations, extensively used in coal, metal, and non-metal mining sectors. Its core components include Conveyor Belts, driving devices, roller systems, tensioning devices, and control systems, enabling continuous transportation of ores, coal, and other bulk materials. Key advantages feature ultra-long conveying distances (single unit up to 15km), high capacity (peak 6000 t/h), stable operation, and low maintenance costs. Proper equipment selection can boost transportation efficiency by over 30% while enhancing safety.

Complex mining conditions (slopes/humidity/material abrasiveness), diverse specifications (belt width 500-2400mm), and variable supplier capabilities create dual challenges in technical adaptation and procurement channels.

Procurement Channel Analysis for Mining Belt Conveyors

E-commerce Platform Procurement

Despite being a new industrial procurement avenue, purchasing heavy-duty mining equipment online presents limitations:

- Quality Verification Difficulties: Over 40% of platform products have inflated parameters; remote inspection cannot validate critical indicators (e.g., whether ST6300-grade steel cord belt tensile strength meets standards)

- After-Sales Service Gaps: 85% of shops lack on-site technical support, with failure response times exceeding 72 hours

- High Communication Costs: Non-technical customer service leads to >30% misunderstanding of critical parameters like inclination requirements/explosion-proof ratings

Agent Channel Procurement

Agents offer brand consolidation advantages but inherent drawbacks:

- Price Premiums: Intermediary links increase equipment costs by 18-25% (e.g., $12,000+ gap for 100m DTIIA-type conveyors)

- Technical Disconnects: Agents lack mastery of core parameters (e.g., drum lagging thickness, idler L10 life expectancy)

- Unreliable Service: 67% of after-sales responsibilities involve manufacturer-agent disputes (Mining Equipment Industry Survey)

Direct Factory Procurement

Recommended through source manufacturers like Zoomry:

- Quality Traceability: Direct access to material certifications (e.g., belt cover abrasion ≤90mm³) and factory test reports

- Cost Optimization: Eliminating intermediaries reduces costs by ≈22% compared to agent channels

- Full-Lifecycle Service: Geological survey → engineering design → installation → operator training → spare parts supply (<24h response)

-

Deep Customization: Supports special configurations: tunnel curves (R≥60m radius), steep inclines (>28°), arctic operation (-45°C)

Key Decision Factors for Mining Belt Conveyor Procurement

1. Precision Selection Based on Three Dimensions

| Dimension | Critical Metrics | Industry Requirements |

|---|---|---|

| Material Properties | Size/density/humidity/abrasiveness | Iron ore (4.5t/m³ density) needs reinforced rollers |

| Operating Conditions | Slope/distance/ambient temperature | Open-pit mines require cold-resistant drives |

| Performance Targets | Capacity(t/h)/continuous runtime | Metal mines demand 24/7/365 operation |

2. Customized Solutions - Core Efficiency Drivers

Zoomry's modular design system:

- Terrain Adaptation: Horizontal curve conveyors reduce transfer points (15% energy savings)

- Smart Drives: Permanent magnet direct drives save 23% energy vs. traditional reducers

- Safety Enhancement: IoT-based anti-tear systems (±5cm detection accuracy)

3. Critical Component Quality Benchmarks

- Conveyor Belt: Must comply with MT668 standard (steel cord breaking strength ≥25kN/mm)

- Idlers: Labyrinth-sealed with ≤2.5N rotation resistance (60,000-hour service life)

- Drive Unit: Reducers meeting ISO281 standard with 50,000-hour L10 life

4. Full Lifecycle Service Ecosystem

Zoomry's triple-layer guarantee:

- Preventive Maintenance: Vibration sensors provide 2-week early warnings for bearing failures

- Spare Parts Network: 12 global warehouses (72-hour emergency delivery)

- Digital Twin: AR-assisted remote maintenance (40% faster troubleshooting)

ZOOMRY

ZOOMRY