How to Choose a Conveyor Belt

Conveyor systems have several moving parts and components to power them. Idlers, winches, bearings, couplings, gearboxes, motors, fluid couplings, and scrapers all work together to move material from point A to point B. The conveyor belt is one of the most commonly overlooked parts of a conveyor setup.One of the most commonly overlooked parts of a conveyor setup is the conveyor belt itself. This critical component helps support the product and transport it safely to its intended destination.

What is a conveyor belt?

A conveyor belt is one of the most important components of a conveyor system. It transports ore and other materials from the mining site to the processing facility or loading area.The conveyor belt is powered by a motor that runs on electricity or other energy sources.

Depending on the application and a number of other considerations, the composition of the belt may include plastic or rubber compounds, fabric materials, and steel cords. It is supported by rollers that allow it to move ore and other materials safely and efficiently at predetermined speeds.

Conveyor Belt Composition

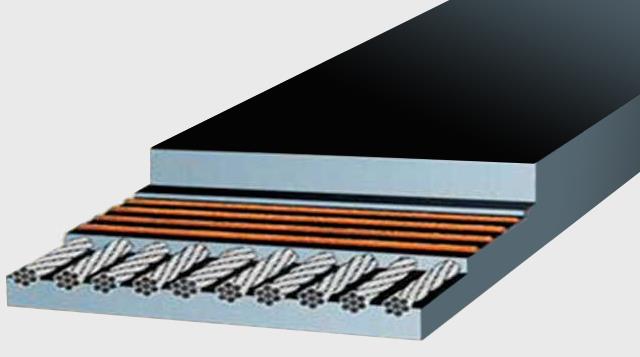

Conventional conveyor belts consist of three layers:The top layer, or cover, is the layer upon which the product is transported.

The middle layer, also known as the carcass, helps support the conveyor belt. The carcass is often made of metal or braided fabric.

Finally, there is the bottom cover to complete the make-up of the belt.

What are the different types of conveyor belts?

Choosing the right type of conveyor belt is critical to ensuring safe and reliable operation. Using the wrong belt can lead to disastrous consequences and unplanned downtime.Here are the different types of conveyor belts available

Multi-Ply - consists of multiple layers of fabric separated by rubber to help dampen impact. Tends to be more durable and is used in underground applications.

Straight warp - Great for tunnel applications, they are most commonly used in quarries and rock crushers. Impact and tear resistance are the two primary attributes, with yarn and polyamide used on both sides. Straight warp conveyor belts allow for higher troughing at narrower belt widths and higher PIW ratings.

Steel Cord - Steel cables running the entire length of the belt anchor this type of belt for underground applications.

Solid woven belts - these are more popular in Europe and Asia, but are not commonly used in the United States

Heat resistant - designed to withstand high temperatures

Considerations for Choosing Mining Conveyor Belts

If you are purchasing a mining conveyor belt, you should first determine the tensile strength requirements, thickness of the cover, and type of cover based on the material being transported and loaded. Also of particular importance is the operating environment in which the conveyor will transport the material.Conveyors transporting packaged or lightweight materials in temperature-controlled warehouses will not have the same requirements as conveyors transporting heavy products underground in mines and quarries.

This is why application and environment should be the two primary considerations when selecting a mining conveyor belt.

Above or below ground?

The main difference between above and below ground mining belts is the materials used in the manufacturing process. Standard above ground or above ground mining conveyor belts consist of highly flammable petrochemicals. If used in an underground mining application, the conveyor belt is likely to burn and pose a serious safety hazard.Underground

Underground mining belts are made from flame retardant materials. Special reagents, impregnating pastes and rubber components are added during the manufacturing process to help reduce the coefficient of friction and increase fire resistance.

Above Ground/Earth

The choice of above ground belts depends primarily on the characteristics of the raw material being conveyed. The level of moisture, particle size and wear characteristics are all important factors in this decision.

For example, highly abrasive materials such as iron ore, metallurgical coke and quartz require a more robust conveyor belt than moderately abrasive materials such as ash or sand.

Nature of the material to be transported

Under ideal conditions, mining conveyor belts have an average service life of three to ten years, depending on length, conveyor design, and so on. The nature of the bulk material you are transporting can also significantly affect the life of the belt.For example, sharp, jagged, abrasive materials can damage the belt more quickly. That's why it's important to choose a belt that's designed specifically for your application and is well supported in the loading area.

Fire Resistant

If your mining conveyor operates in an underground environment, it may have to meet MSHA Part 14 fire protection requirements. Make sure you are fully aware of the rules and regulations that may affect the type of belt you choose for your conveyor to ensure that you are operating at the highest level of safety, not to mention staying compliant.Lifespan

Some belts last longer than others and certain factors such as longevity and durability are important depending on the specific type of environment.Conveyors running underground or transporting materials from mines and quarries place higher demands on belts than lines transporting empty boxes in factories.

Understand your needs in terms of durability and robustness. Failure to take this into account can lead to reduced productivity and increased downtime.

Pulley Diameter

Depending on the thickness of the belt fabric from top to bottom, you need to consider the pulley diameter recommended by the manufacturer.Corrosion resistance

Belts can corrode, especially those containing metal. While corrosion may not be as much of a concern in climate-controlled facilities, it can pose a challenge for underground conveyors that are prone to fluctuating temperatures, UV rays, humidity levels and moisture.Belt width and length

Since not all belts are made for the same application, they don't all come in the same width or size.For example, the width and length of the belts you see on a conveyor belt system at the checkout counter of a grocery store is much smaller than the belts you'll find when transporting products in an underground mine.

While many belts can be customized to fit the desired length and width, it's best to know your sizing requirements.

Temperature

The temperature of the material you are transporting is another important consideration. For example, rock and ore coming directly from the ground can reach temperatures as high as 220° F. While this is not enough to cause a belt to catch fire, it can cause irreparable damage.Conveyor belts with specific thermal properties can help mitigate damage caused by hot materials.

Check out our Mining Conveyor Belt Maintenance Guide.

FAQs

Q: What is a coal conveyor belt?A: Coal conveyor belts are specifically designed to safely and efficiently transport coal from one area to another.Zoomry has over 20 years of experience manufacturing custom conveyors for the coal mining industry.

Q: What types of mining use conveyor belts?

A: Coal, rock, precious metals, iron ore, lead and lithium are just a few examples of mining operations that use conveyor belts.

Q: What is a quarry conveyor belt?

A: Quarry conveyor belts transport materials such as sand, gravel, rock, marble or crushed stone from the quarry to the end point.

Q: What is the TPH in conveyor?

A: The acronym "TPH" stands for "tons per hour" and is a key measurement in determining the ideal conveyor belt for use on a mining conveyor system. It measures how many tons of rock or ore a conveyor belt moves per hour.TPH is related to belt speed or the speed at which the belt is moving.

Choosing the best mining conveyor belt

Don't overlook mining conveyor belts when designing a conveyor system for your next project. While there are many different types of conveyor belts to choose from, they are a key part of the overall puzzle that helps ensure productivity and not only meets but exceeds your profit goals.

ZOOMRY

ZOOMRY