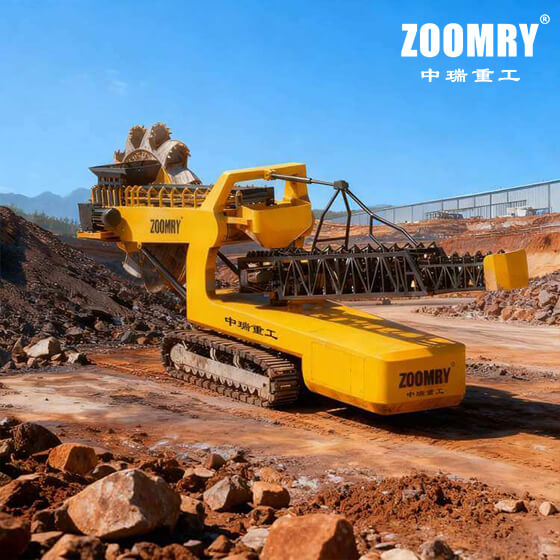

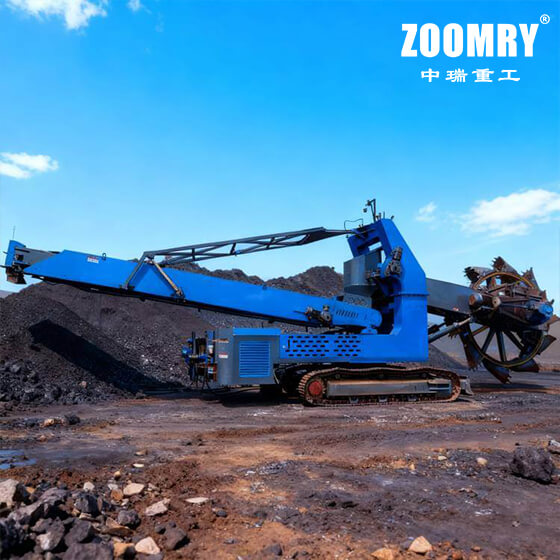

The ZOOMRY Bucket Wheel Stacker Reclaimer is a mobile continuous operation equipment centered on a bucket wheel excavation device, integrating bulk material stacking and reclaiming functions. Its core feature is breaking free from fixed track constraints — equipped with a crawler traveling system, it can move freely on soft and uneven sites without the need for preset stockyard facilities. It is widely applicable to non-fixed operation scenarios such as mine stope, infrastructure temporary stockyard, and port transfer area, efficiently handling bulk materials like coal, ore, and sandstone.

The equipment achieves integrated operations through the coordinated operation of mechanical, hydraulic, and electrical systems. The motor drives the bucket wheel to rotate, and the buckets on the rim penetrate the material pile to scoop up materials, which are then transported to the boom conveyor via the guide chute. During stacking, external materials are conveyed through the boom, and with the rotation of the machine body and the luffing of the boom, fixed-point or small-range fan-shaped stacking is completed. The hydraulic crawler drive supports stepless speed regulation and in-situ steering, while the electrical system is equipped with intelligent monitoring functions to provide real-time early warnings for issues such as material blockage and deviation. Only 1-2 operators are required for operation.

Compared with traditional equipment such as loaders, the bucket wheel stacker reclaimer’s integrated stacking and reclaiming design eliminates the need for frequent equipment replacement. Its operating efficiency is 3-6 times that of loaders, with a single-unit hourly processing capacity of 500-3000 tons, suitable for large-scale 24/7 continuous production. The low track ground pressure enables stable operation on uneven sites with a slope of ≤15°, and it has strong adaptability to the particle size and humidity of various bulk materials. Additionally, the equipment consumes less energy than intermittent operation equipment, has a long maintenance cycle for wearing parts, and offers more competitive long-term operating costs.

It focuses on large-scale mobile operation needs: in mine stopes, it can stack and reclaim raw coal and ore on-site, reducing long-distance transportation; in temporary bulk cargo areas of ports, it can quickly complete stacking after unloading and transfer for loading without fixed tracks; at large infrastructure project sites, it can flexibly handle sand and gravel aggregates to ensure continuous construction.

Three key points should be emphasized when selecting: choose wear-resistant or anti-adhesive models according to material characteristics, select crawler specifications based on site conditions, and prioritize products with lightweight bodies, universal wearing parts, and fast after-sales response to ensure compatibility with on-site operation requirements.

ZOOMRY

ZOOMRY