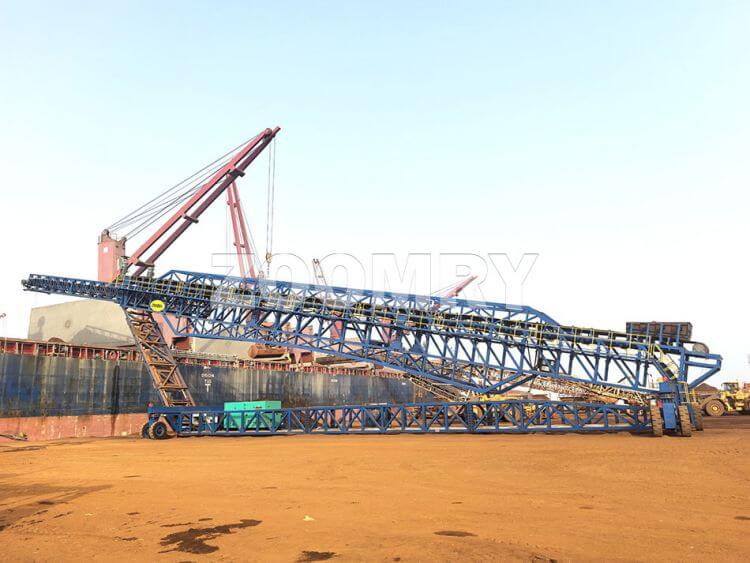

The mobile shiploader is a highly flexible bulk material handling equipment, essentially an extension and expansion of telescopic stacker technology. It achieves free transshipment across the entire terminal through tire or crawler chassis, completely eliminating the infrastructure constraints of traditional rail-mounted equipment. Its core features lie in the telescopic hydraulic boom system (typically covering 45-70m working range) and intelligent remote control system. Operators can precisely complete the entire operational process of material retrieval, conveying, and ship loading using wireless terminals.

The 3500TPH model introduced by Zoomry Heavy Industries, with its peak handling capacity of 3,500 tons per hour, has become core equipment for large bulk ports to enhance turnover efficiency and reduce operating costs, playing an irreplaceable role in the circulation fields of bulk materials such as coal, ore, and grain.

I. Technical Advantages of Zoomry Mobile Shiploader

Greater Flexibility and Versatility

The Zoomry Heavy Industries mobile shiploader completely liberates itself from the constraints of rails and concrete foundations. Adopting a fully hydraulically driven multi-axle tire chassis (crawler version optional), the equipment can complete berth transfers in minimal time. The hydraulic automatic leveling system ensures the equipment maintains horizontal operation on dock surfaces with 5° slopes, with the four-point support structure achieving rigid locking within 30 seconds. Wind resistance reaches 20m/s, and port throughput utilization increases to over 95%.

| Traditional Shiploader Limitations | Zoomry Mobile Shiploader |

|---|---|

| Requires pre-cast concrete foundations and rails | Tire/crawler chassis adapts to dock terrain |

| Serves 1-2 berths per unit | Single unit covers 8 berths, utilization increases by 95% |

| 6-month installation cycle | 72-hour rapid deployment |

Human-Machine Intelligent Remote Control

Zoomry's remote control system establishes a three-tier interaction ecosystem: At its core is the PLC-based fully automatic loading mode, which creates real-time 3D stockpile models through hatch-scanning LiDAR and dynamically optimizes material-throwing trajectories; handheld remote controllers grant operators wireless control of 16 functions including travel, steering, and boom operations within a 500-meter range; on the HMI touchscreen, 63 sets of sensor data pulsate, monitoring everything from belt tension to hydraulic oil temperature.

- PLC Fully Automatic Loading: Pre-sets material flow curves, dynamically adjusts throwing trajectories through real-time hatch capacity scanning

- 500m Wireless Remote Control: Handheld terminal controls 16 functions including boom telescoping/luffing/rotation

- HMI Human-Machine Interface: Touchscreen monitors flow rate, tension, energy consumption data in real-time

Green, Eco-Friendly and Efficient

When the mobile shiploader boom retracts from a -22° depression angle, dissipated potential energy is converted into electricity. Actual measurement data show that a single luffing motion can recover 30kWh of electricity, equivalent to 18% energy savings when loading 3,000 tons of iron ore. A 25-meter turning radius adapts to narrow docks, while cooperating with the dry mist dust suppression system to compress dust emissions to <5mg/m³. The dual-mode power solution (diesel generator/high-voltage slip ring power supply) better adapts to areas with weak power grids, enabling green port upgrades without being constrained by infrastructure.

- Dual-mode Power System: 400kW diesel generator set (non-electrified areas) or 10kV high-voltage slip ring power supply

- Potential Energy Recovery Technology: Boom downward motion generates electricity feedback, reducing energy consumption by 18%

- Enclosed Chute Conveying: Paired with dry mist dust suppression system, dust emissions <5mg/m³

II. Protection Mechanisms and Key Parameters

Load-Bearing Capacity

The full 65-meter length achieves complete coverage for Capesize vessel types, its secret lying in an innovative truss structure. The main structure welded with Q345B special steel adopts a variable cross-section design: the root section height reaches 2.8 meters to resist bending moments, while the end tapers to 1.2 meters to reduce self-weight. Fatigue tests show that when bearing peak loads, the structural safety factor reaches 4.5 times, far exceeding ISO 20332 standard requirements.

| Indicator | Parameter | Industry Standard Comparison |

|---|---|---|

| Peak Capacity | 3500 TPH | Leads similar models by 23% |

| Working Radius | 65m | Covers Capesize vessel type |

| Luffing Angle | -15°~+22° | Adapts to docks with 6m tidal range |

| Turning Radius | 25m | Reduced by 64% vs traditional equipment |

Transmission System

A core indicator of loading efficiency is material flow stability. Zoomry's hydraulic winch system features dual braking circuits paired with a mechanical self-locking device responding in 0.01 seconds, enabling instantaneous locking even if steel cables suddenly rupture. Engineering tests demonstrate that when loading iron concentrate with density of 1.8t/m³, flow fluctuation rate is controlled within ±1.5%, avoiding cabin partial loading risks.

Environmental Adaptation

The entire machine is equipped with 32 wind speed sensors. When detecting 15m/s wind speed, it automatically activates counterweight balance mode; if reaching 20m/s, hydraulic locking devices activate, with 4 sets of pin shafts penetrating the chassis to form rigid anchoring. Facing high-temperature and high-humidity environments, hydraulic oil is equipped with an independent cooling circuit, ensuring system pressure stability under 55℃ working conditions.

| Vessel Type | DWT (tons) | Hatch Height (m) | ZRSL-60 Adaptability |

|---|---|---|---|

| Handysize | 10,000-35,000 | 4-8 | Full cabin coverage |

| Panamax | 60,000-80,000 | 10-14 | No vessel shifting required |

| Capesize | 80,000-120,000 | 16 | Dual-machine coordinated operation |

III. Zoomry Heavy Industries Global Service Network

- Dynamic Simulation Design: Generates loading trajectory simulations based on port GIS data

- Modular Pre-assembly: Field splicing efficiency increased by 70%, reducing installation risks

- Intelligent Operation & Maintenance System: AR remote diagnosis supports 4-hour response

- Bonded Parts Network: 50-country storage coverage, critical components delivered within 72 hours

IV. User Decision-Making Guide

Technologically-Oriented Research Needs

The hydraulic drive system uses closed-loop circuits collaborating with proportional valve groups to enable stepless adjustment of boom telescoping speed within the range of 0.1m/s to 1.5m/s. Even when conveying high-viscosity nickel ore with 15% moisture content, the flow fluctuation rate remains stably controlled within ±1.5%. The dynamic load balancing algorithm automatically compensates for dock ground deviations of up to 3° by real-time analysis of tilt sensor data, ensuring the machine's inclination is less than 0.5° under full-load conditions. Researchers can further verify the engineering effectiveness of the potential energy recovery system—its 18% energy-saving efficiency during luffing operations has obtained third-party certification from TÜV Rheinland, with relevant data complying with the "ISO 5048:2019" energy consumption testing specifications.

Procurement Evaluation Needs

Core considerations should focus on the equipment's full lifecycle value creation capability: The key to significantly lower per-ton loading/unloading costs than the industry average lies in zero rail infrastructure investment, coupled with structural optimization of operational costs achieved through the dynamic energy recovery system; shortened return on investment cycles stem from the asset reuse rate enhancement created by the multi-berth sharing mode, with actual measured data showing single-unit service coverage capacity reaching over three times that of traditional equipment. Vessel type adaptability is ensured through modular boom design—the 65-meter working radius combined with -15° to +22° luffing angles can seamlessly match operations from Handymax to Capesize vessel types. The global support system establishes a digital service network, with IoT-based predictive maintenance systems compressing unplanned downtime to industry minimum levels, and the bonded warehousing network ensures ultra-fast response for critical components.

Project-Critical Implementation Needs

For typhoon-prone sea areas: The equipment integrates meteorological response protocols—wind speeds exceeding 15m/s trigger four-point hydraulic locking; reaching 20m/s activates mechanical pin shaft rigid anchoring, with actual measured wind resistance capability reaching Level 12. The crawler version's ground contact pressure <80kPa adaptability ensures settlement remains stable within 3cm under 6-meter tidal range conditions. The safety system adopts triple braking redundancy—hydraulic disc main brakes (0.3-second response), electromagnetic power-off backup brakes, and 0.01-second mechanical self-locking during steel rope rupture constitute a multi-layered protection system. Customized services extend to terrain modeling and material adaptation—drone scanning generates port GIS models for dynamic path planning, while exclusive control protocols enable mixed conveying of coal and iron ore, maintaining flow fluctuation rates below 5% even when density differences reach 3 times.

ZOOMRY

ZOOMRY