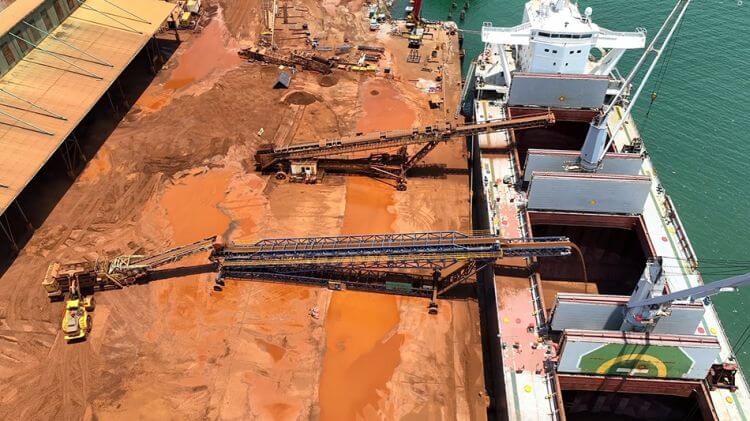

In the core hubs of bulk material maritime transportation, the corrosiveness of sulfur, hygroscopicity of fertilizers, high abrasiveness of iron ore, and light and loose characteristics of palm kernel shells result in distinctly different performance requirements for loading equipment across various bulk material types. Take Zoomry Heavy Industry's ZRSL series mobile ship loaders as an example. As commonly used mobile bulk material conveying equipment in ports, they boast high professionalism, stability, and adaptability. Targeting these differentiated needs, they have formed adaptive solutions in multiple industrial scenarios such as mining, chemical industry, and ore processing.

Requirements of Different Bulk Materials for Mobile Ship Loaders

There are various types of bulk materials commonly seen in ports, with significant differences in their physical and chemical properties, leading to obvious distinctions in their performance requirements for loading equipment. For instance, sulfur, as a typical low-melting-point and corrosive bulk material, requires prevention of high-temperature melting and leakage corrosion during handling; fertilizers, due to their tendency to absorb moisture, agglomerate, and cause dust pollution, have strict requirements for equipment sealing and material integrity protection; iron ore, being a high-hardness and highly abrasive material, demands resistance to particle impact and dust diffusion; palm kernel shells/palm kernel meal are lightweight and prone to dust emission, and palm kernel meal is susceptible to moisture-induced agglomeration. Therefore, mobile ship loaders need to possess the following core adaptive capabilities:

- Material sealing performance: Prevent dust spillage (e.g., fertilizers) or corrosive gas leakage (e.g., sulfur) to reduce environmental risks and material loss;

- Adaptive adjustment: Flexibly adjust conveying speed, inclination angle, and stacking methods according to material particle size, humidity, and other parameters to avoid agglomeration or scattering;

- Corrosion resistance and wear resistance: Resist the erosion of equipment structures by corrosive materials like sulfur, while withstanding long-term friction from fertilizer particles.

The basic performance framework of Zoomry Heavy Industry's ZRSL series mobile ship loaders provides guarantees for cross-bulk material operations: The equipment adopts full hydraulic drive for radial, telescopic, and luffing functions, allowing operators to precisely control loading positions through remote control or PLC fully automatic mode; The entire machine has obtained international certifications such as CE, EAC, and KCS, directly meeting the compliance requirements of overseas markets like Europe, Russia, and South Korea.

Performance in Sulfur Handling

As an important chemical raw material, sulfur faces two core challenges during handling: first, its low melting point (approximately 115°C), which makes it prone to melting and adhering to equipment in high-temperature summer environments; second, sulfur dust is corrosive, and long-term exposure can cause rusting of metal components.

Anti-Corrosion Design

- Material upgrade: Unlike traditional ship loaders that use ordinary carbon steel, Zoomry's ship loaders for sulfur scenarios adopt 316L stainless steel for key components (such as Conveyor Belts and roller surfaces). The chromium-nickel alloy composition forms a passivation film, improving sulfur corrosion resistance by 300% compared to ordinary steel. In laboratory salt spray tests, this material showed no obvious rust after continuous operation for 5000 hours in a simulated sulfur vapor environment.

- Sealing protection: The entire machine adopts an "all-enclosed" sealing structure. Double-layer rubber skirts are installed on both sides of the conveyor belt, with the gap between the skirts and the frame controlled to ≤2mm, effectively preventing sulfur dust from entering the interior of the equipment. Meanwhile, transmission components such as bearings are equipped with IP67-grade dust covers to avoid jamming faults caused by dust adhesion.

Temperature Control and Anti-Melting

- Conveyor belt cooling system: An optional air-cooled cooling module can be installed, which introduces external cold air under the conveyor belt through pipelines to control the belt surface temperature below 50°C.

- Low-speed and stable conveying: The conveying speed is reduced from the conventional 2.5m/s to 1.8-2.0m/s through the PLC control system, combined with an 18° inclination angle design, reducing frictional heat generation of sulfur particles during conveying and lowering the risk of melting.

Safety Redundancy Design

- Emergency shutdown response: Equipped with a dual-trigger emergency stop system, which supports both remote control (response time ≤0.5s) and automatic shutdown via conveyor belt deviation switches and tension sensors. During sulfur handling, if abnormal belt surface temperature or seal failure is detected, the equipment will immediately shut down and activate an audible and visual alarm.

- Explosion-proof configuration: In view of the flammable and explosive characteristics of sulfur dust, components such as motors and electric control boxes adopt ATEX-certified explosion-proof versions, complying with the EU EN 13000 standard and adapting to safety regulations in regions such as Europe and Southeast Asia.

Performance in Fertilizer Handling

Granular fertilizers such as urea and compound fertilizers are prone to absorbing moisture and agglomerating, and dust leakage can cause soil and water pollution.

Anti-Agglomeration

- Adjustable conveying inclination angle: Dynamically adjust the conveying inclination angle (5°-15° stepless adjustment) according to the moisture content of fertilizers. When the moisture content is >10%, a low inclination angle (≤8°) is adopted with an anti-slip conveyor belt to avoid agglomeration caused by rolling and collision of particles.

- Flexible unloading device: A buffer chute is installed at the unloading end, with polyurethane wear-resistant plates laid inside. The chute angle can be adjusted through a hydraulic system (0°-30°), allowing fertilizer particles to fall into the cargo hold at a speed of ≤3m/s, reducing impact crushing. Meanwhile, the chute outlet is equipped with a dust curtain, reducing dust diffusion to ≤10mg/m³, which is better than international environmental standards.

Efficient Cleaning

- Four-fold cleaning system: Polyurethane (PU) scrapers are respectively installed at the head and tail of the machine, combined with rotating brushes and high-pressure air blowing devices, achieving over 99% removal of residues on the conveyor belt surface. For easily adherent compound fertilizers, optional heated scrapers (temperature controlled at 40-50°C) can be installed to prevent material adhesion and mildew.

- Hopper anti-residue design: The receiving hopper adopts a combination structure of a conical bottom and a vibrator, with the hopper wall inclination angle ≥60°, combined with 30Hz high-frequency vibration, ensuring complete sliding of fertilizer particles. The residue is controlled within 0.5kg per batch, far lower than the industry average of 2-3kg.

Environmental Protection and Compliance

- Dust collection and recovery: An optional negative pressure dust collection system can be equipped, which sucks the dust generated at the unloading point into a dust collection box through pipelines, and achieves a dust recovery rate of >95% after filter bag filtration. The recovered fertilizer dust can be re-granulated for reuse, reducing waste and complying with the EU REACH environmental regulations.

- Low-noise operation: The drive motor adopts SEW/FLENDER silent gearboxes, combined with rubber shock-absorbing pads, and the overall operation noise is ≤75dB, meeting the noise limit standards of ports around residential areas (such as the 70dB nighttime limit of the US EPA).

Performance in Handling Other Common Materials

Iron Ore Handling

The high hardness (Mohs hardness 5-6) and large particle size (≤300mm) of iron ore require the equipment to have strong wear resistance.

- Application of wear-resistant materials: The conveyor belt adopts a multi-layer nylon core + ultra-high molecular weight polyethylene covering layer, and the surface of the drive roller is sprayed with a tungsten carbide coating (hardness HV1200), with wear resistance improved by more than 4 times compared to ordinary equipment.

- High-efficiency operation capability: The ZRSL-60 model is equipped with a 90kW hydraulic power pack, with a loading capacity of up to 1500 tons per hour. Through the "radial stacking + continuous conveying" mode, the utilization rate of the wharf site is increased by 28%.

Palm Kernel Shells/Palm Kernel Meal

The lightness of palm kernel shells (density 0.4-0.6t/m³) and the hygroscopicity of palm kernel meal.

- Lightweight and efficient conveying: Adopts an aluminum alloy frame and a thin-walled conveyor belt (thickness 3-5mm) to reduce operating energy consumption; The ZRSL-40 model has a conveying speed of 3.0m/s, combined with a 20° inclination angle design, meeting the rapid loading and unloading needs of palm kernel shells.

- Humidity and dust emission control: A microwave humidity sensor is installed at the hopper inlet. When the moisture content of palm kernel meal is >12%, infrared heating (40-50°C) is automatically activated; The unloading end is designed with a 360° full-rotation short belt, with a material throwing speed of 15m/s, combined with a multi-stage dust removal system (dust emission ≤15mg/m³), complying with environmental protection requirements.

General Performance Advantages of Zoomry Mobile Ship Loaders

Whether for special bulk materials such as sulfur and fertilizers, or conventional materials such as iron ore and palm kernel shells, the general performance design of Zoomry mobile ship loaders demonstrates industry-leading levels.

Efficient Operation and Adaptability

- Radial telescoping and luffing functions: The telescopic arm length of the ZRSL series ship loaders can be adjusted within the range of 15-30m, combined with a ±110° radial rotation angle, covering different cargo hold sizes from barges (100-5000DWT) to Panamax ships (60000-80000DWT). One equipment can meet the loading needs of fertilizers, sulfur, and coal simultaneously, with a switching time of ≤30 minutes.

- High capacity output: Adopting a 55kW-90kW hydraulic drive system, the single-machine hourly loading capacity can reach 800-1500 tons. Compared with traditional fixed ship loaders, through the "radial stacking + continuous conveying" mode, the utilization rate of the wharf site is increased by 28%, and the loading and unloading time per ship is shortened by 15-20%.

Intelligent Operation

- PLC fully automatic control: Equipped with a programmable logic controller, supporting preset loading processes (such as "layered stacking" and "edge distribution"), and realizing one-key operation through an HMI touch screen. In the unattended mode, the equipment can automatically adjust the unloading position according to the data from the cargo hold level sensor, with the precision controlled within ±30cm.

- Remote monitoring and diagnosis: Equipped with 4G/5G communication modules, which can upload operating data (such as motor temperature and conveyor belt speed) to the cloud platform in real-time. Zoomry Heavy Industry's overseas technical team can realize fault diagnosis through remote access, with an average response time of ≤2 hours, solving the after-sales pain points of overseas customers.

Stability and Reliability

- Strict testing and certification: All ship loaders must pass the "extreme working condition tests" of Zoomry Heavy Industry's quality inspection center, including 72-hour continuous full-load operation, -20℃ to 50℃ high and low-temperature environment tests, etc., to ensure stable performance in extreme climates. The equipment has obtained international certifications such as ISO 9001, CE, and EAC, directly adapting to mainstream markets such as Europe, America, and Russia.

- Low maintenance and long service life: Key components (such as rollers and bearings) adopt maintenance-free design, with a service life of ≥50000 hours; The hydraulic system is equipped with oil filtration and cooling devices, extending the oil change interval to 2000 hours, reducing maintenance costs by 50% compared to the industry average. Meanwhile, the entire machine provides a 5-year warranty, and core components have an extended warranty of up to 8 years, significantly reducing the customer's whole-life cycle costs.

ZOOMRY

ZOOMRY