Product information:

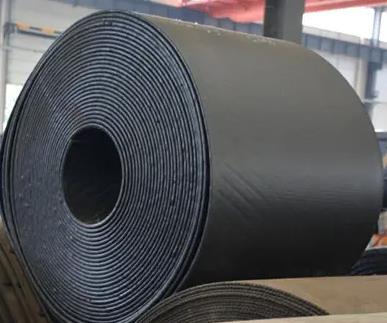

The chain bucket ship unloader is a type of continuous ship unloading equipment for bulk commodities that uses a chain bucket to remove materials from the ship's cabin before using the onboard conveying system to dump the bulk materials onto the pier. Chain reclaiming hoisting mechanism, materials reception mechanism, cantilever crane rotation mechanism, cantilever crane pitching mechanism, traveling mechanism, belt-type conveyor system, etc. are the components that make up the chain-type ship unloader. The chain bucket may remove the materials from the ship cabinet when it is unloaded. Finally, utilize the belt-type conveyor system on the dock to transport the goods by using the central funnel and discharging belt-type conveyor.

Why you choose chain bucket ship unloader?

1. High ship unloading efficiency: While the grab ship unloader only accounts for 45%–50% of the rated production efficiency, the average ship unloading efficiency can account for 55%–60% after the ship unloader has entered the stripping stage.

2. It has low pollution: Dust cannot easily escape since the material conveyance pathways are blocked, with the exception of the reclaimer head.

3. Low energy usage: the grab ship unloader's energy consumption ranges from 1.62 to 1.8MJ/t.

4. Stable operation: The continuous operating mode is the primary cause.

5. Its operation is simple to automate: It is simple to operate and straightforward to automate and semi-automate.

ZOOMRY

ZOOMRY