What Type of Cover Closure is Used for belt conveyors When Mobile Reception and Conveying

Trough belt conveyors are generally in an open state, during bulk material receiving and transportation, rain, wind and snow protection cannot be realized, and dust overflow cannot be avoided. In order to meet the requirements of environmental protection, it is necessary to place the open trough conveyor in a closed environment.There are various ways to realize the closure.

Rain Cover is the standard equipment of the belt conveyor, which is a kind of closed way.The rain cover has various structural forms, and can be semi-closed or fully closed to the conveyor. When unloading at the fixed point, combined with the closed guide chute, it can better realize the whole process of bulk material conveying closed.

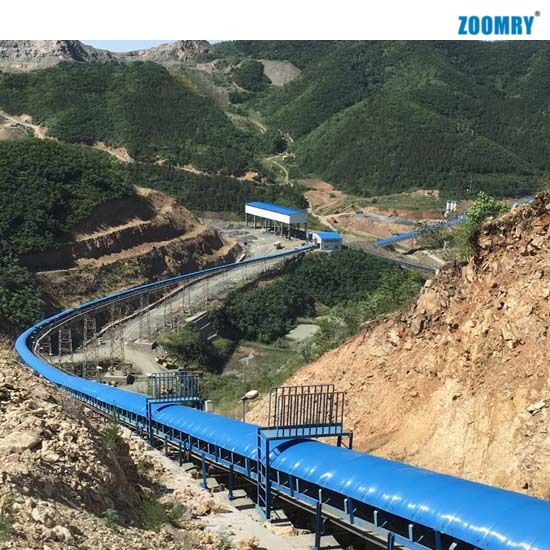

Placing the conveyor throughout the closed gallery as well as the pipe belt machine program are environmentally friendly measures to solve the environmental problems of the conveying process, and can be sheltered from the wind and rain to reduce material loss.

In the face of continuous movement of the receiving material, and can not meet the requirements of environmental protection closed. The following briefly introduces and analyzes several kinds of covering devices of belt conveyor that can realize continuous moving receiving material in the current market.

1. 'Zipper' type cover belt

Herringbone-shaped covering belts of equal width are hung from the tops of both sides of the middle frame of the belt conveyor to completely cover the belt surface. When the ship unloader is moving, use the unloading bracket on the machine to open the herringbone comb. After leaving, the bracket will close automatically. The whole action is like pulling a zipper.

The more prominent problem of this way is that the tape is easy to deform under such working conditions, the sealing becomes worse, and the dust suppression effect is not good.

2.Reversing pulley winding type (belt conveyor covering belt)

This method is the whole belt mounted on the Conveyor Belt conveyor bearing belt above, in order to facilitate the movement of the material, combined with the characteristics of the mobile receiving point, by increasing the reversing pulley group, so that the covering belt winding through the receiving point, the receiving point will be wrapped in the covering, to achieve the effect of the whole process of closure. The end needs to be equipped with a tensioning device to tauten the cover belt.

This kind of covering belt has better dust removal effect and less damage to the belt, but the shortcoming is that it needs to modify the mobile unloading device, increase the redirection of the Reversing Winding pulley and the necessary closed structure.

3.Reversing pulley winding type (closed corridor covering belt)

The nature of this method is the same as the second, also belongs to the reversing pulley winding closed, the difference is that its cover belt is combined with the closed corridor, as part of the closed corridor roof, mobile unloading point through the closed corridor above the passing, the cover belt through the winding in the reversing pulley, upward to avoid the unloading point, and then transversely cover the unloading point, and then folded down to return to the corridor roof.

The combination of mulch strips and enclosed porches adds to the difficulty of designing the enclosed canopy structure and increases the structural cost of enclosing the porch, but the overall enclosure is better.

ZOOMRY

ZOOMRY