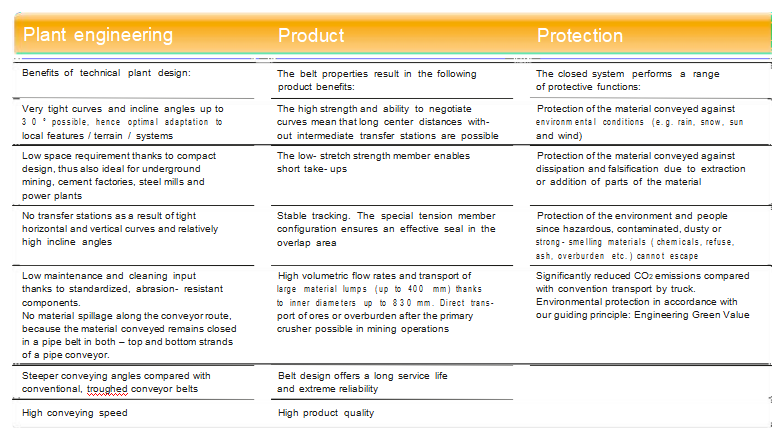

A Pipe conveyor differs from a conventional,troughed belt in its design and splicing technology and performs special conveying tasks.Mining and industrial applications often require relatively large inclines and tight curves to be overcome in tight spaces and at high mass flow rates.

The particular features of modern pipe belt conveyors include:no transfer points,no material spillage along the conveyor route,and tight30°curves.Pipe belt conveyors save space thanks to their compact design,navigate natural and infrastructural terrains,including steep conveyor angles up to 30°.

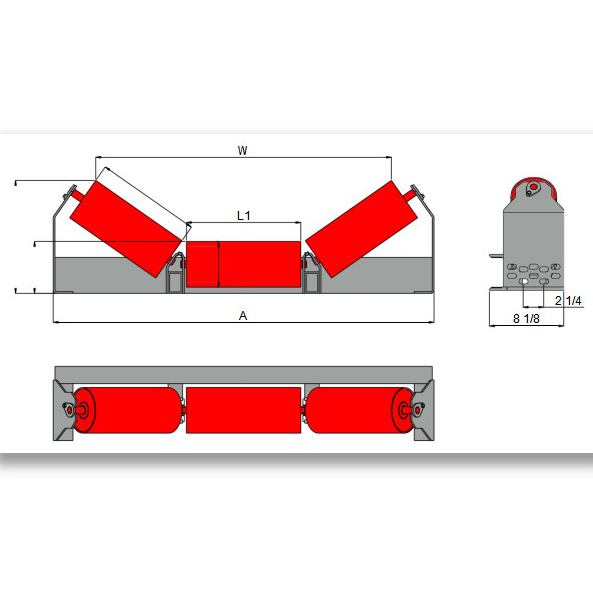

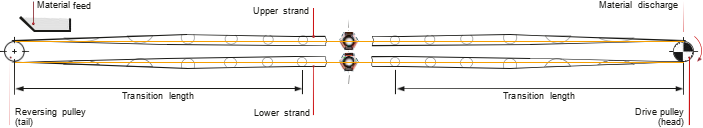

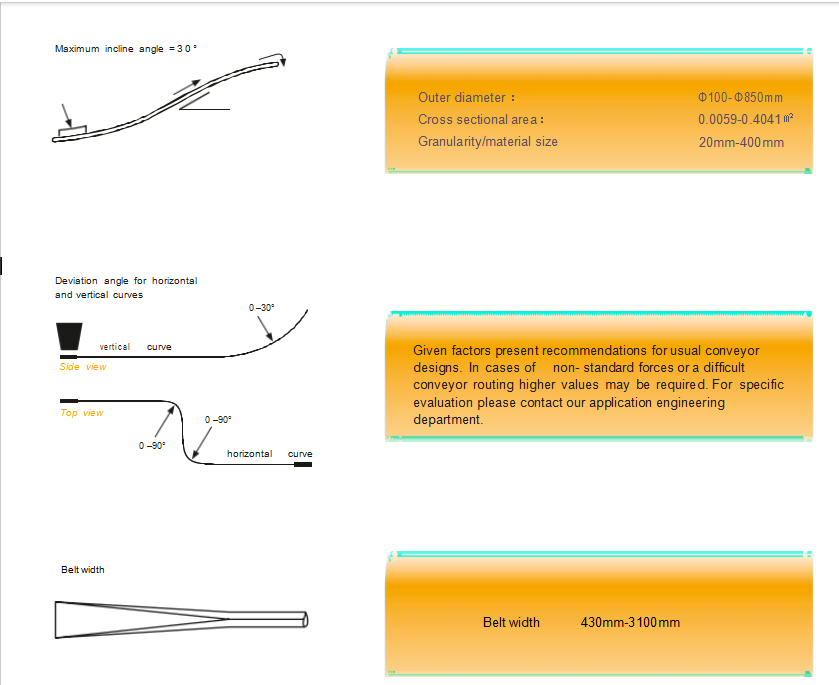

Design and function of the pipe conveyor system

Properties of the pipe belt conveyor system

In addition to consistent quality and technical reliability,highly engineered pipe belt conveyor systems offer a range of other benefits.

Details

Belt Sway Switch

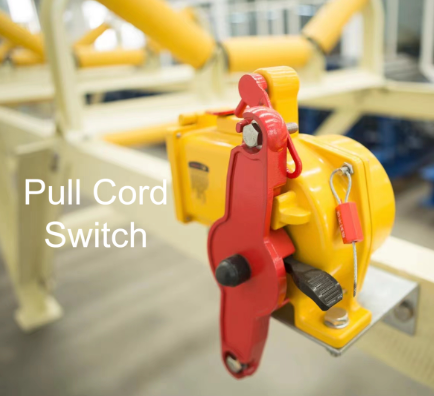

Detect whether the belt is deviating and send out a slight alarm or shutdown signal.Deviation will damage the belt and cause safety accidents.Deviation switches need to be purchased and installed in pairsPull Cord Switch

Pull the wire rope to realize the switch action,which is used for emergency shutdown.It is a safety switch and is arranged along the entire length of the fuselage.When an emergency occurs on the belt conveyor,the conveyor can be stopped urgently at any position.There are single-sided and double-sided arrangements.They are generally used in conjunction with walkways.

Zero Speed Switch

Detect whether the belt is slipping with the head roller.After slippage occurs,the Conveyor Belt speed will decrease.When the transport volume is overloaded,the belt tension is insufficient,or the rubber layer of the driving roller is worn out,slippage may easily occur.The conveyor belt speed can be monitored(also the rotational speed is calculated)or the drum rotation speed can be monitored.If the belt conveyor in the stacker encounters an unexpected situation,such as a power outage or a broken wire rope,the stacker has a self-protection function:

1.The winch motor has a self-locking function of 0.01 seconds when the power is cut off

2.The stacker has 2 mechanical mechanisms If stuck,the internal unit will not slip to the bottom all at once.There are two designs in the middle to prevent jamming.

ZOOMRY provides knowledge,experience,a globally encompassing and competent network and a broad product range to give your conveyor belt applications a technological lead.More than 20 years of Material transportation and storage expertise make us a strong partner,enabling our customers to benefit from the synergies within the ZOOMRY corporation.We implement innovative conveyor belt technology reliably,sustainably and safely from development to commissioning and after-sales service.

Video

For belt conveyor and mobile telescopic stackers,if to make the machine running for long time,client need to do the vulcanizing at site.

We can supply the vulcanizing machine with the telestacker or long distance belt conveyor system.

The site vulcanizing work can be done with the following steps:

ZOOMRY

ZOOMRY