The performance characteristics of troughing idler:

1. The troughing idler has the characteristics of corrosion resistance: it is difficult for acid, alkali and salt to corrode it.

2. Troughing rollers have strong hardness: strong wear resistance.

3. Good sealing: the troughing idler is fully sealed, and the plastic labyrinth seals are installed at both ends, so that the oil and grease will not leak, so that the rolling shaft can be long-term; the troughing idler runs in a fully sealed state.

4. Troughing idler ceramic surface: an oxide film is formed, the surface is smooth, no material is adhered, and the friction coefficient of contact with the Conveyor Belt is small, which reduces the driving force of the hoisting.

5. Long service life of grooved idler: the use time of troughing idler is 2-5 times longer than that of steel idler, and it can reduce belt wear, the belt does not run sideways, and prolongs the service life of the belt.

6. Low operating cost: The troughing idler can reduce the overall cost of the belt conveyor and reduce maintenance man-hours.

Troughing rollers are widely used in open-air dusty and highly corrosive environments, such as mines, power plants, steel mills, stone plants, cement plants, coal washing plants, salt plants, alkali plants, fertilizer plants, docks and other transportation places.

More details:

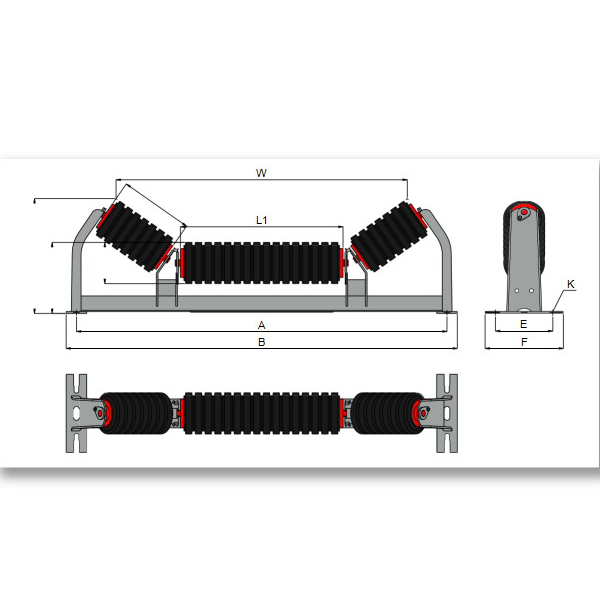

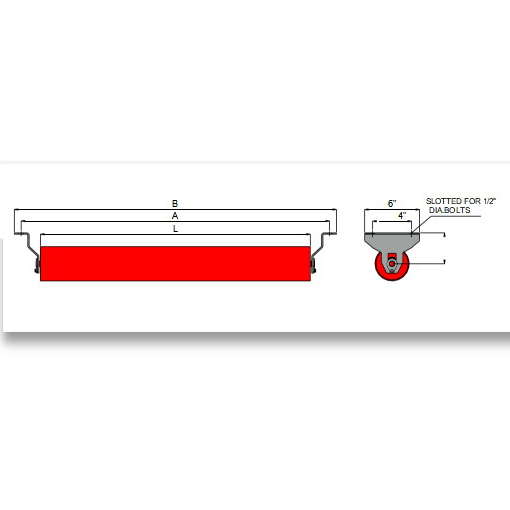

It mainly used for the support of the carrying side of the belt conveyor. It is the principal device for supporting the belt and the conveyed materials.

Material:

Q235 idler, ceramic idler, high frequency welded pipe idler, polymer idler

Why You Choose Zoomry Troughing Carrying Idler?

1. Side brackets with deep created channels for further strength.

2. Center stands that don't clog.

3. Small roller gap sizes.

4. Strong foot pads with bolt mounting.

5. long lifespan.

ZOOMRY

ZOOMRY