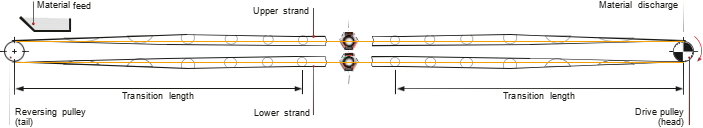

Pipe conveyor is kind of special which is also named tubular conveyor. The belt is folded into a tubular shape with overlap by six idler rolls forming a hexagon. The main benefits of pipe conveyors are their ability to accommodate sharp curves and seal the transported material.

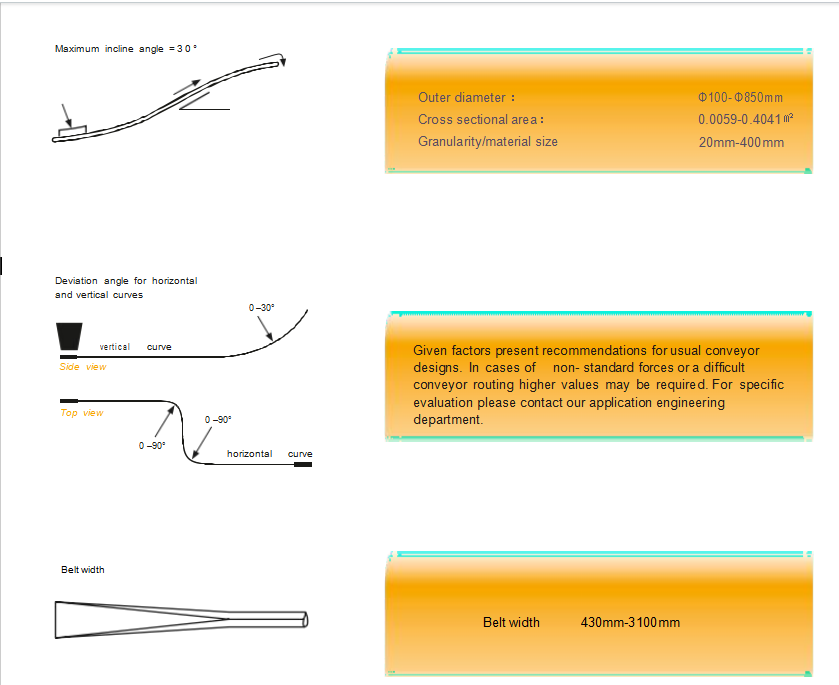

Speciafication

Type

Nominal pipe diameter

Pipe ID(mm)

Belt Width(mm)

CSA (m2)

Granularity Max(mm)

JKGD01

100

100.2

430

0.0059

20~30

JKGD02

150

150.7

600

0.0134

30-50

JKGD03

200

199.1

780(800)

0.0234

50~70

JKGD04

250

263.5

1000

0.0409

70~90

JKGD05

300

285.2

1100(1200)

0.0479

90~100

JKGD06

350

334.3

1300(1400)

0.0658

100-120

JKGD07

400

426.5

1600

0.1071

120~150

JKGD08

500

509.5

1900(2000)

0.1529

150-200

JKGD09

600

603.5

2250

0.2145

200-250

JKGD10

700

690.6

2550

0.2809

250-300

JKGD11

850

828.1

3100

0.4041

300-400

(mm)

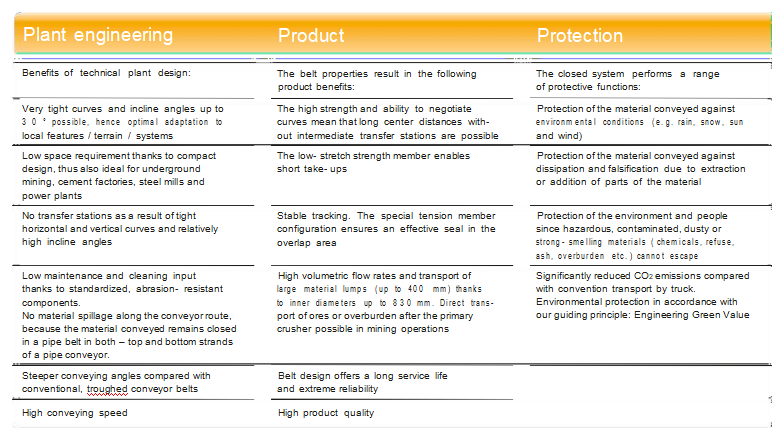

Design and function of the pipe conveyor system

Properties of the pipe belt conveyor system

In addition to consistent quality and technical reliability, highly engineered pipe belt conveyor systems offer a range of other benefits.

Detail

Belt Sway Switch

Detect whether the belt is deviating and send out a slight alarm or shutdown signal. Deviation will damage the belt and cause safety accidents. Deviation switches need to be purchased and installed in pairs

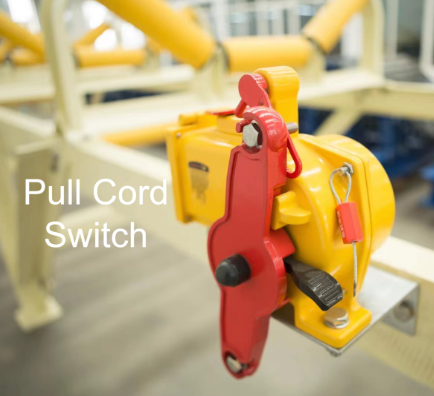

Pull Cord Switch

Pull the wire rope to realize the switch action, which is used for emergency shutdown. It is a safety switch and is arranged along the entire length of the fuselage.

When an emergency occurs on the belt conveyor, the conveyor can be stopped urgently at any position. There are single-sided and double-sided arrangements. They are generally used in conjunction with walkways.

Zero Speed Switch

Detect whether the belt is slipping with the head roller. After slippage occurs, the Conveyor Belt speed will decrease. When the transport volume is overloaded, the belt tension is insufficient, or the rubber layer of the driving roller is worn out, slippage may easily occur. The conveyor belt speed can be monitored (also the rotational speed is calculated) or the drum rotation speed can be monitored.

If the belt conveyor in the stacker encounters an unexpected situation, such as a power outage or a broken wire rope, the stacker has a self-protection function:

1. The winch motor has a self-locking function of 0.01 seconds when the power is cut off

2. The stacker has 2 mechanical mechanisms If stuck, the internal unit will not slip to the bottom all at once. There are two designs in the middle to prevent jamming.

For belt conveyor and mobile telescopic stackers, if to make the machine running for long time, client need to do the vulcanizing at site.

We can supply the vulcanizing machine with the telestacker or long distance belt conveyor system.

The site vulcanizing work can be done with the following steps:

How to do the site Conveyor belt vulcanizing

ZOOMRY

ZOOMRY