Conveyor impact bed is a device installed at the loading point of a Conveyor Belt to absorb shock and impact from falling material. The conveyor impact bed is designed to cushion live loads. It absorbs a large amount of energy from the material falling onto the belt at the loading point. The chain, UHMW blocks and rubber supports work in concert to absorb heavy loads at the transfer point.

Features:

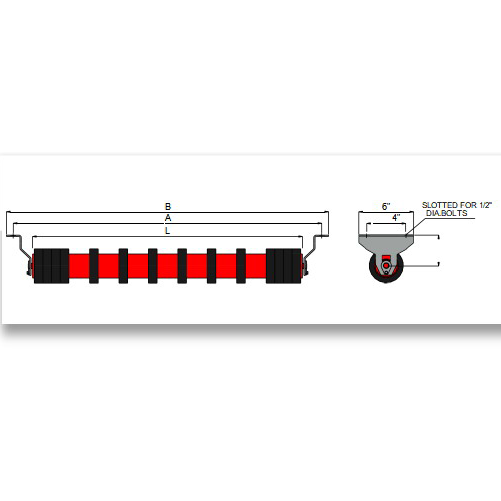

1. Low friction UHMW for the top layer and high impact SBR rubber for the bottom layer.

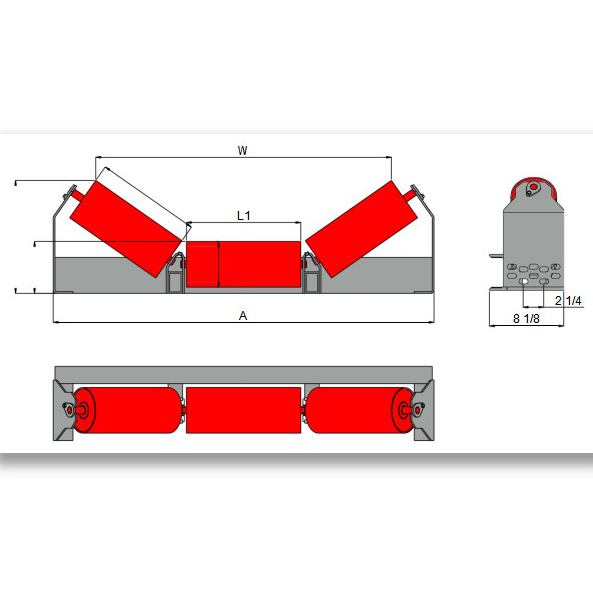

2. Wings adjust to 20°, 35° and 45° to accommodate material transferred to the loading area.

3. Strong, structurally sound frame provides additional support.

4. Extends the life of the main conveyor belt by up to 3 times.

5. Reduces belt perforation and damage.

6. Reduces cushion roller consumption.

7. Increases equipment availability.

8. helps to increase the tonnage of the conveyor belt.

Applications:

Mining: Impact beds are commonly used in the mining industry to protect conveyor belts from falling rocks and debris.

Material Handling: Impact beds are used in material handling systems to absorb the shock of falling packages and other items.

Aggregate Conveying: In the aggregate industry, impact beds protect conveyor belts from impact damage caused by heavy loads.

Overall, the use of a conveyor impact bed can increase the longevity of a conveyor system, reduce maintenance costs, and ensure smooth, safe operations.

Specifications table:

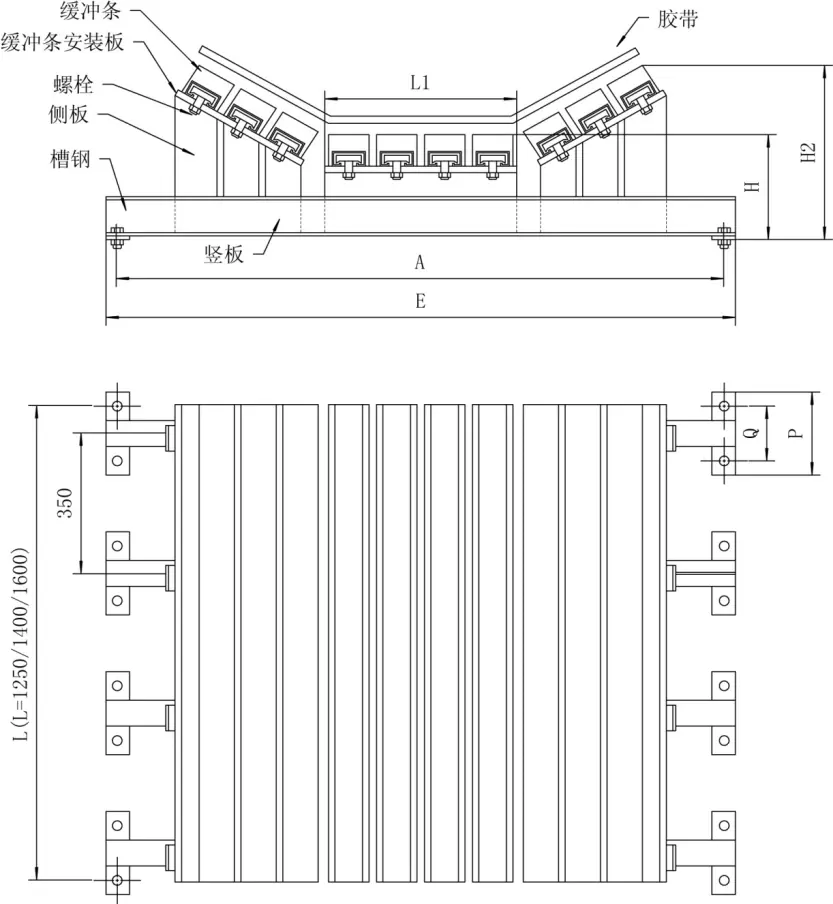

Parameter analysis: belt conveyor belt width: B=(1200) mm;

The belt conveyor groove angle is (35) degrees; H is (179) mm; the buffer strip length is (1400) mm.

The distance from the bottom of the belt frame to the center of the horizontal buffer idler in our factory is 179mm, and the distance from the bottom of the belt frame to the surface of the upper belt is 248mm.

What should you tell our engineers?

Some conveyor dataBelt width (inches)

Belt speed (FPM)

Buffer bed length e.g. 300mm

Material (type and maximum block size)

Material density (lbs/ft3 or t/m³)

Chute roller angle and roller diameter

Material drop height

Selected operating data

Conveyor name/label

Conveyor capacity (sTPH)

Altitude (ft)

Operation (days/year)

ZOOMRY

ZOOMRY