Bulk material handling scenarios in global ports share common characteristics such as diverse material types, large throughput fluctuations, limited operating space, and stringent environmental requirements. Under traditional models, problems such as manual guidance-dependent truck unloading, frequent blockages in the feeding process, material segregation and pollution during shipping are prevalent. These not only lead to low operational efficiency (single-ship loading cycle extended by over 30%) but also result in 10%-15% material loss, along with compliance pressures such as excessive carbon emissions and safety accident risks.

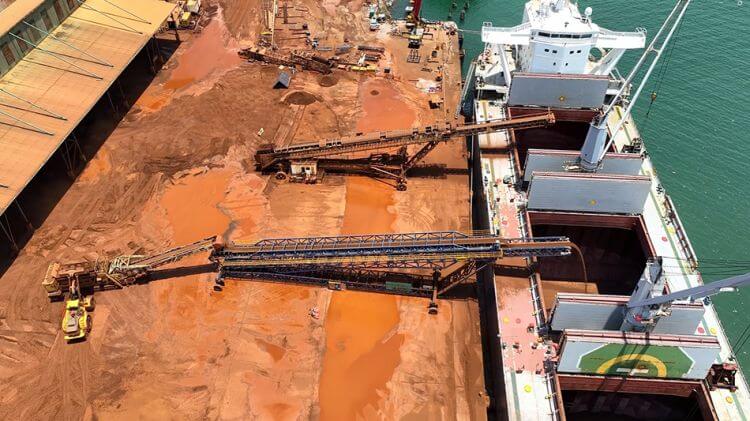

ZOOMRY's integrated solution achieves full-process optimization through functional complementarity of three core equipment: the truck unloader rapidly receives bulk materials from land transport, the hopper feeder completes material buffering, homogenization and stable feeding, and the mobile shiploader efficiently fulfills ship loading. The three form a seamless connection of "land transport - transfer - maritime transport", adapting to site conditions, material characteristics and compliance requirements of different ports worldwide, and achieving significant results in improving operational efficiency, reducing material loss and cutting carbon emissions.

Core Equipment Technical Analysis

mobile shiploader

ZOOMRY's mobile shiploader covers the full range of ship adaptation needs from barges to Capesize vessels (80,000-120,000 DWT), making it the preferred equipment for bulk material maritime transport in global ports.

In terms of technical configuration, the equipment adopts a full hydraulic drive system and PLC automatic control, supporting switching between three modes: fully automatic, remote control and manual operation. Operators can precisely adjust actions such as radial rotation, telescoping and luffing of the equipment through a touchscreen HMI. The maximum rotation angle can reach 110°, far exceeding the 70° limit of traditional belt conveyors, adapting to flexible operations in narrow port spaces. In terms of throughput, the ZRSL series products have a maximum conveying capacity of 3,000 tons per hour, capable of meeting the rapid loading needs of large Panamax and Capesize vessels, with a single-ship loading cycle shortened by 20%-30% compared to traditional equipment.

In terms of environmental protection and material protection, the equipment effectively controls dust diffusion through a closed conveying design and rubber skirt sealing, with noise levels below 45dB, complying with environmental standards of EU CE certification and Russian EAC certification. Meanwhile, the optimized material flow trajectory design reduces material impact and friction, avoiding segregation, crushing and pollution, making it particularly suitable for bulk materials with high quality requirements such as coal, chemical fertilizers and grain. In terms of structural design, the equipment can be disassembled and transported in 40ft high containers, with on-site assembly taking only 10-20 days. Equipped with a tracked or wheeled chassis, it can not only quickly transfer on hardened roads but also adapt to stable operations on soft port sites, significantly reducing infrastructure and transportation costs.

Truck Unloader

ZOOMRY's truck unloader offers two chassis options: wheeled (ZRLS-TU series) and tracked (ZRLD-TU series), with belt widths ranging from 1400mm to 1800mm and throughput from 200 tons per hour to 1800 tons per hour, enabling rapid unloading of bulk materials from trucks of different tonnages. Its core advantage lies in rapid unloading capacity—completing the unloading of 30 tons of bulk cargo in only 3-10 minutes, shortening the time by over 60% compared to traditional unloading methods, and significantly improving truck turnover efficiency. In terms of safety design, the equipment integrates a dual emergency braking system, full protective covers for drive components and CE certification-compliant design, which can brake instantly in case of emergencies, while preventing operators from accidental contact injuries, ensuring safe and stable high-intensity operations in ports.

Modular design is another highlight, supporting the selection of 2-lane or 4-lane truck ramps, combined with optional configurations such as radio remote control and hydraulic slope adjustment. Users can flexibly adjust according to port site size and truck flow. In terms of environmental protection, it reduces material dust by optimizing the unloading process, while reducing the frequency of trucks traveling to and from storage yards, indirectly reducing fuel consumption and carbon emissions, in line with the global trend of port green transformation.

Hopper Feeder

ZOOMRY's hopper feeder adopts a large-caliber hopper design (width 3.5m-5.7m, capacity 5-24m³ customizable), combined with 60-70° inclined sidewalls and 6mm hardened steel liners, effectively preventing blockages and hopper wear. It can directly receive feeding from loaders, excavators or grab cranes without prior stacking and transfer, with operational efficiency improved by 40%-60% compared to traditional methods. The conveying system is divided into belt conveying (light/medium models, suitable for 0-250mm bulk materials) and chain plate conveying (heavy-duty models, suitable for large ore lumps). Equipped with PLC frequency conversion speed regulation technology, it can accurately match the processing capacity of downstream mobile shiploaders, avoiding conveying interruptions caused by too fast or too slow feeding.

In terms of power selection, three modes are available: diesel-hydraulic (no power supply scenario), hybrid (energy-saving type) and pure electric (environmental protection scenario). Among them, pure electric and hybrid models comply with EU Stage V/Tier 4 Final international emission standards, and the electrical system reaches IP65 dust and water resistance level, adapting to environmental compliance requirements in different regions such as Europe, America and Southeast Asia. In terms of mobility, the tracked chassis has low ground pressure (80kPa), adapting to soft port grounds; the wheeled chassis enables flexible transfer, and static models are suitable for fixed operating areas, fully meeting the needs of different port site conditions.

Trinity Synergistic Advantages

Efficiency Multiplication

The three pieces of equipment form a continuous operation chain of "truck unloading - hopper buffering - shipping output". After the truck unloader rapidly unloads materials, the hopper feeder provides stable feeding through homogenization, avoiding frequent start-stop of the mobile shiploader caused by uneven material supply. The automated control and large throughput design of the mobile shiploader achieve precise matching of "unload as much as possible, convey as much as possible, load as much as possible".

Cost Reduction and Efficiency Improvement

- Equipment Level: Modular design reduces transportation and installation costs (the mobile shiploader can be disassembled for transportation, reducing on-site assembly costs by 30%);

- Operational Level: Automatic control reduces labor demand by 80%, improved truck turnover efficiency lowers transportation costs, and material loss is reduced from 10%-15% to below 3%;

- Maintenance Level: ZOOMRY has its own production lines for core components such as idlers, rollers and cleaning scrapers. The service life of equipment wearing parts is 30% longer than the industry average. The centralized lubrication system and large-size access door design reduce maintenance time and costs by 50%.

Environmental Compliance

The sealed design of the truck unloader and hopper feeder, and the dust control technology of the mobile shiploader jointly control the port operation dust concentration below 5mg/m³, complying with EU GB 28661-2012 and US EPA environmental standards. The power selection of pure electric and hybrid models reduces energy consumption and carbon emissions by 20%-25%, helping ports achieve the "carbon neutrality" goal. The equipment noise is below 45dB, creating a low-noise operating environment and adapting to the stringent global environmental requirements for ports.

Safety and Reliability

Full-process safety design covers equipment operation, operators and material transportation: the mobile shiploader is equipped with steel wire rope breakage mechanical limit and power-off automatic locking system; the truck unloader is equipped with dual emergency braking and anti-miscontact protective covers; the hopper feeder is equipped with blockage alarm and emergency stop protection. All equipment has passed international safety certifications such as CE, EAC and KCS, complying with ISO 9001 quality system and ISO 14001 environmental system standards. It can achieve 24/7 continuous and stable operation in harsh port environments such as high temperature, high humidity and high dust, with a mean time between failures (MTBF) exceeding 5,000 hours.

Flexible Adaptability

The solution has strong adaptability and can be flexibly adjusted according to port scale, material type, ship tonnage and site conditions:

- Material Aspect: Adapts to more than 10 types of bulk materials such as coal, iron ore, grain, cement and biomass, efficiently handling particle sizes from 0-250mm;

- Ship Aspect: Covers the full range from barges (100-5,000 DWT), handy-sized ships (10,000-35,000 DWT), Panamax ships (60,000-80,000 DWT) to Capesize ships (80,000-120,000 DWT);

- Site Aspect: Wheeled and tracked chassis adapt to hardened roads, soft sites and narrow spaces, while static models are suitable for fixed operating areas, meeting the differentiated needs of ports worldwide.

International Port Application Case

In an iron ore handling project at a large international hub port, the customer faced core challenges such as high throughput demand, diverse ship types (from barges to Panamax ships), and stringent environmental and safety compliance requirements. Based on the customer's actual operating scenario, ZOOMRY customized a combined solution of "ZRLS-TU1800 wheeled truck unloader + heavy-duty tracked hopper feeder + ZRSL-50 mobile shiploader":

- Efficiency Improvement: The 1800mm wide truck unloader rapidly receives ore from transport trucks with a maximum throughput of 1,800 tons per hour. Combined with the hopper feeder with 24m³ hopper capacity and 3,000 tons per hour throughput for stable feeding, the mobile shiploader accurately matches the loading needs of Panamax ships. The single-ship loading cycle is shortened by over 50% compared to the traditional model, and the overall operational efficiency is significantly improved;

- Cost Optimization: The automated control process greatly reduces the number of on-site operators. The material loss rate is reduced from the traditional 12% to 2.8%, significantly lowering labor and material loss costs. The hybrid power configuration reduces equipment energy consumption by 23%, greatly saving energy-related expenditures, and demonstrating prominent long-term operational cost advantages;

- Compliance Achievement: Through full-process sealed design and environmental technology optimization, the on-site dust concentration is controlled below 3mg/m³, and the noise is below 42dB, fully meeting stringent international environmental and safety standards, helping the customer successfully pass relevant port certification audits.

The successful implementation of this project fully verifies the adaptability and practical value of ZOOMRY's integrated solution in large international port scenarios. It has now become the core support system for bulk material handling at this port and is referenced and adopted by many international ports as a high-quality case.

Choose ZOOMRY

Founded in 2002, ZOOMRY is a professional bulk material handling equipment manufacturer and EPC contractor. Its core competitiveness stems from technical accumulation, quality control and global service network, providing comprehensive guarantees for the integrated solution:

- Technical Level: The company has four testing centers including chemical laboratory, hardness laboratory and idler laboratory, with more than 60 testing equipment. Products comply with international standards such as ISO 9001, ISO 14001, CEMA, CE, EAC and KCS. Core components (idlers, rollers, cleaning scrapers, etc.) are independently produced, with idler radial runout ≤ 0.4mm (better than the national standard of 0.5mm) and service life exceeding 50,000 hours, ensuring long-term stable operation of equipment;

- Service Level: ZOOMRY provides "EPC+M+O" full-life-cycle services, including solution design, equipment manufacturing, on-site installation, commissioning and training, spare parts supply, equipment overhaul and upgrade. It has established service outlets on five continents worldwide, responding to customer needs 24/7 to ensure uninterrupted port operations;

- Global Layout: The company's products have been exported to more than 30 countries and regions in Europe, Russia, Southeast Asia, South America, etc., adapting to port standards, environmental requirements and cultural backgrounds in different regions. It has completed thousands of bulk material handling projects and served nearly 200 global customers, establishing a good reputation in industries such as mining, ports, power and cement.

Under the global trend of port bulk material handling transforming towards "efficiency, green, intelligence and compliance", ZOOMRY's integrated solution of "mobile shiploader + truck unloader + hopper feeder" provides practical, quantifiable and replicable value solutions for global port customers through equipment synergy, technical upgrading and full-process optimization. Whether it is capacity improvement of small and medium-sized ports or international upgrading of large hub ports, the solution can help customers stand out in fierce international competition with its flexible adaptability, international standard compliance and cost advantages.

ZOOMRY

ZOOMRY