In the links of centralized ore stockpiling in mines and bulk material transfer in ports, the issues of "high capacity" and "high flexibility" have always been pressing problems to address. When a mine's daily mining output exceeds 80,000 tonnes and a port's daily cargo unloading volume surpasses 50,000 tonnes, traditional stackers either cause material backlogs due to insufficient capacity, fail to adapt to irregular sites due to their fixed structures, or even face environmental penalties due to material loss and excessive dust emissions.

Core Requirements for Mines and Ports

- Compatibility of high capacity with continuous operation: Mines need to undertake centralized stockpiling of crushed ores (a single production line usually produces 80,000-100,000 tonnes of ores per day), and ports need to quickly transfer unloaded bulk materials (to avoid high costs caused by cargo ship detention at the port). The equipment must achieve stable output with a capacity of 3500 TPH, and be capable of full-load operation for more than 16 consecutive hours without the risk of frequent shutdowns;

- Flexible adaptation to complex sites: Mine stockpiling areas may have terrains such as slopes and soft ground, while port terminals have limited space and need to adapt to unloading positions of cargo ships of different tonnages. The equipment must have three flexible features: "telescoping + radial rotation + mobility" to avoid reduced stockpiling efficiency due to site constraints;

- Equal emphasis on low loss and compliance: For mine ores (such as iron ore and copper ore), excessively high crushing rates during the stacking process will directly affect the subsequent smelting quality; ports need to comply with environmental standards such as EU CE and Russia EAC (dust concentration ≤ 10 mg/m³). Traditional equipment often leads to material spillage and excessive dust emissions due to insufficient sealing, resulting in local regulatory penalties.

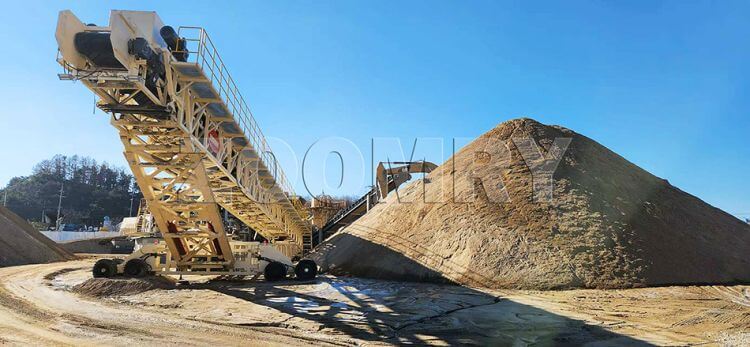

Features of Zoomry 3500TPH Mobile Stacker Conveyor

Zoomry Heavy Industry's Mobile Stacker Conveyor has undergone technical optimizations based on the material characteristics (ore density of 1.6-2.8 t/m³, differences in bulk material fluidity such as coal/aggregates) and operating condition characteristics of mines and ports:

High Capacity Assurance

- Power System: Adopts SEW/FLENDER (optional) gear motor with a power of 55 kW, matched with an electro-hydraulic power pack with a 500-650 L oil tank. This configuration has been tested in Zoomry Heavy Industry's Mechanical Performance Laboratory and can continuously output stable torque within an ambient temperature range of -30℃ to 50℃. Even when facing impact loads from high-hardness ores in mines, there will be no power attenuation;

- Conveying Structure: Uses an EP200-type wear-resistant Conveyor Belt with a width of 1600 mm (flame-retardant and anti-static version optional, suitable for coal mine scenarios). The belt speed is controlled at 2.8 m/s, which not only prevents material spillage caused by excessive speed but also ensures no sagging of the conveyor belt under full load through "dense idler sets" (spacing ≤ 1000 mm), thus guaranteeing stable capacity.

- Stockpiling Efficiency: The radial rotation angle reaches ±110° (far exceeding the industry standard of ±70°), with a telescoping stroke of 20 m and a maximum stacking height of 20 m. In mine stockpiling areas, a single unit can cover a stockpiling area of 432 m², and the stockpiling capacity is 28% higher than that of fixed stackers; in port terminals, the stacking range can be flexibly adjusted according to the positions of cargo ship berths, avoiding secondary material transfer.

Scenario Adaptability

- Mobility and Support Design: Adopts a dual-option crawler/wheeled chassis (crawler type for soft terrain in mines, wheeled type for hardened ground in ports). The chassis frame is made of integrally forged high-carbon steel, and key load-bearing joints are inspected via ultrasonic flaw detection, capable of withstanding the total weight of the equipment's own weight plus full-load materials (over 60 tonnes); at the same time, it is equipped with hydraulic jacks, which can quickly fix the equipment during stacking operations to prevent machine tilt caused by slight ground settlement;

- Self-Power Supply and Emergency Support: Considering that some mines and ports lack stable power supply, the equipment can be pre-installed with a diesel generator to achieve "self-powered operation" without relying on external power sources. In case of a sudden power outage, the hydraulic winch system will automatically lock the telescopic arm within 0.01 seconds, and the steel cables will trigger dual mechanical limits simultaneously, ensuring the safety of the equipment and materials and avoiding the risk of boom falling caused by power outages.

- Low Loss and Environmental Protection: A 15 mm thick polyurethane liner is installed inside the chute, controlling the crushing rate of materials during falling to within 1.5% (lower than the industry average of 3%); the two sides of the conveyor belt are equipped with 150 mm high wear-resistant rubber side guards, which cooperate with the three-stage sealing (elastic plate + wear-resistant steel + brush) of the head guide chute. The material loss rate is ≤ 0.3%, and the dust concentration can be controlled at 8 mg/m³, complying with the EU EN 15251 environmental standard.

Intelligent Control

- Three-Mode Operation: Supports full-automatic PLC, remote control, and manual operation. In full-automatic mode, trajectories such as "fan-shaped stacking" and "layered stacking" can be preset. Through the HMI touchscreen (supporting multiple languages including English, Spanish, and Russian), the equipment automatically completes coordinated movements of telescoping, rotation, and luffing. A single unit can reduce 2 operators, saving over 120,000 US dollars in annual labor costs;

- Fault Prediction and Diagnosis: The equipment is equipped with built-in temperature and vibration sensors to monitor the status of core components such as idlers (temperature ≤ 80℃) and motors (vibration frequency ≤ 2.5 mm/s) in real time. Once abnormalities occur, early warning information will be immediately sent to the operation and maintenance team; in case of a fault, technicians can access the equipment operation logs through remote video calls. 70% of common faults (such as idler jamming and conveyor belt deviation) can be resolved by guiding local personnel, without the need to dispatch engineers across borders.

Choose Zoomry Heavy Industry's 3500TPH Mobile Stacker Conveyor

Multi-Standard Adaptation and Compliance Certifications

- Design Standards: Supports mainstream industry standards such as CEMA (USA), AS (Australia), and GB (China), and can adjust structural parameters according to the technical requirements of target markets; for highly corrosive operating environments, customized stainless steel idler brackets can be provided to enhance rust resistance; for explosion-proof operating scenarios, the conveyor belt can be made of anti-static and flame-retardant material to meet the ATEX certification standard, ensuring safe operation in flammable and explosive environments;

- Compliance Certifications: The equipment has obtained CE (EU), EAC (Russia), and KCS (South Korea) certifications, and also complies with the requirements of ISO 9001 quality management system and ISO 14001 environmental management system. The entire process from design, production to delivery follows international standards, avoiding market access issues caused by lack of certifications and ensuring the smooth implementation of overseas projects.

Efficient Assembly and Component Support

- Pre-Assembly Design: Most components of the equipment (such as telescopic arms and hydraulic systems) are pre-assembled in the factory. On-site assembly and commissioning can be completed in only 10-20 days. Compared with the 30-40 day installation cycle of competitors' products, it can be put into operation 20 days earlier;

- Component Supply: Zoomry Heavy Industry independently produces core components such as idlers, rollers, and cleaning scrapers, and maintains sufficient inventory (the idler inventory can meet the replacement needs of 50 equipment units worldwide). Components are shipped via international logistics (DHL/FedEx). Regular components can be delivered to overseas project sites within 72 hours, and emergency components can be delivered directly via air freight within 48 hours.

Localized Technical Support

- Training and Materials: Upon equipment delivery, 2-3 days of on-site practical training is provided to help the customer's team master daily inspection (such as checking hydraulic oil level daily and cleaning chute residues weekly) and emergency handling skills;

- Remote Support: A 24/7 overseas technical hotline is set up, staffed with professional engineers proficient in English and Russian. They can provide video guidance for operations such as idler replacement and conveyor belt vulcanization. At the same time, operation and maintenance video tutorials are provided to ensure that customers can maintain stable equipment operation without relying on external teams.

ZOOMRY

ZOOMRY