How to use?

The high end of the conveying material is fed into the upper shell, and the compressed air is blown into the lower shell by a special blower, and is distributed among the material particles through the air-permeable layer densely covered with pores, so that the material undergoes so-called gasification to change the friction angle of the material , to form a flow state and slide down the slope to achieve the purpose of transportation.

Advantages:

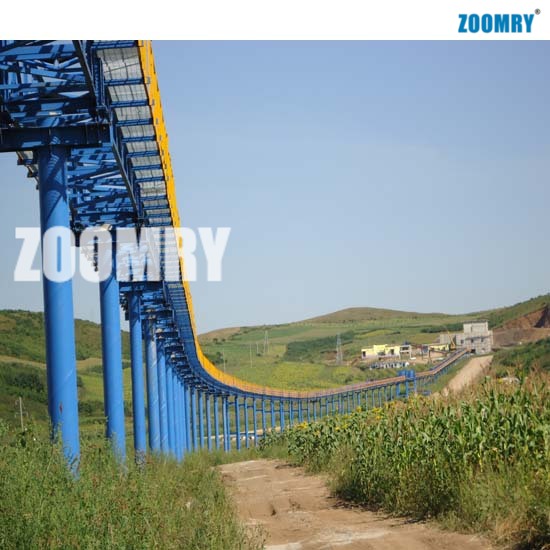

Compared with belt conveyors, screw conveyors, and buried scraper conveyors with the same function, the air chute has no transmission parts in the conveying material, which has less wear, easy maintenance, less power consumption, less material, no noise, and easy operation. At the same time, it is easy to change the conveying direction and has the advantages of multi-point feeding and unloading. Therefore, it has been adopted by many enterprises in recent years.

Technical features:

1. Conveying materials: dry powdery materials.

2. Conveying volume: The conveying volume of the chute is affected by many factors and often changes greatly.

3. Slope: 6% The straight chute is not affected by the flange structure, and the slope can be selected arbitrarily. The slope of the transport cycle grinding coarse material is recommended to be 10%. Generally speaking, when the layout is possible and the wear of the air-permeable layer permits, it is advantageous to use a large slope.

4. Air consumption: 1.5-3 cubic meters per minute, per square meter of breathable layer. Various materials and their states, the condition of the air-permeable layer, and the slope of the chute all have varying degrees of influence on the air consumption. Generally, it can be considered as 2 (cubic meters per minute, square meters of air-permeable layer).

5. Air pressure: 400-600 water column (mm). In the case of large size, long chute, etc., take a larger value. Generally, 500 (mm water column) can be considered.

ZOOMRY

ZOOMRY