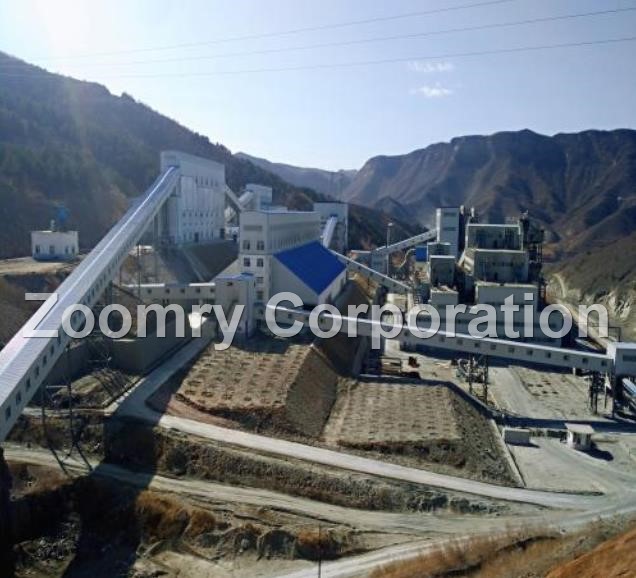

Hubei Wuxue Southeast Mining focuses on the mining, processing and transshipment of iron ore (a core category of sand and gravel aggregates, with a particle size of 5-40mm, moisture content of 4%-7%, high hardness, strong abrasiveness and easy dust generation). With the expansion of production capacity, it is necessary to build a long-distance dedicated conveying line from the mountainous mine crushing area to the plant raw material reserve area, connecting the entire process chain of "mining - crushing - conveying - storage".

Located in rugged mountainous terrain, the mining company's conveying route needs to cross 8,617 meters of sharply undulating terrain and has 7 natural turns. Previously, it adopted a hybrid mode of "ordinary belt conveyor + heavy truck transshipment", which has gradually exposed multiple bottlenecks and become a key obstacle to production capacity expansion:

Due to the constraints of mountainous terrain, the 8,617-meter conveying route requires 4 transshipment stations for ordinary belt conveyors. This not only increases equipment and civil engineering investment, but also leads to a material loss rate of 5.5% due to the high hardness of iron ore and frequent loading and unloading during transshipment; the handling capacity of a single ordinary conveyor is only 1,800 tons per hour, which cannot match Southeast Mining's crushing capacity of 2,500 tons per hour. During peak hours, iron ore is frequently backlogged in the crushing area, with the longest retention time exceeding 8 hours; the open design of transshipment links and truck transportation results in a dust emission of 28mg/m³, far exceeding the limit of 10mg/m³ specified in the Comprehensive Emission Standard for Air Pollutants, leading to frequent environmental complaints from the surrounding area; the sharp undulations of the mountainous terrain and 7 turns make it impossible for ordinary conveyors to be directly adapted, requiring large-scale mountain leveling, which not only damages the ecology but also increases high civil engineering costs; more critically, the core components of the equipment rely on external procurement, with a spare part response cycle of more than 40 days and an annual downtime of more than 120 hours, seriously affecting the continuous production of Southeast Mining's mountainous mining area.

In response to the mountainous terrain, high abrasiveness of iron ore and open-air environment of Southeast Mining, ZOOMRY has designed a full-chain solution of "core conveying equipment + supporting node equipment + independent high-wear-resistant components" to ensure the adaptability and reliability of the system.

Project Overview

Core Requirements

Southeast Mining's requirements revolve around four dimensions: "accurate parameters, scenario adaptation, compliance and reliability, and operation and maintenance support", which are in line with the characteristics of open-air iron ore (sand and gravel aggregate) conveying in mountainous areas:

- Parameter requirements: The core conveying equipment shall have a handling capacity ≥ 2500 tons per hour, a belt width of 1200mm, a conveying length of 8617 meters, and be adapted to 7 horizontal curves (turning radius ≥ 1000 meters, maximum turning angle ≤ 36°). A multi-point drive design shall be adopted to cope with the heavy-load conveying of iron ore;

- Scenario adaptation: The equipment shall withstand extreme temperature differences (42℃ in summer and -10℃ in winter) and rainy weather in the open-air mountainous environment. The protection level of core components (idlers, motors) shall be ≥ IP55. The frame shall resist strong winds and rain erosion in mountainous areas, and at the same time be adapted to the high abrasiveness of iron ore;

- Compliance aspect: Dust emission ≤ 10mg/m³. The equipment shall comply with CEMA standards and domestic environmental protection regulations, and be adapted to the environmental protection requirements for iron ore conveying in the mining industry;

- Operation and maintenance support: The service life of core components (idlers, drums) shall be ≥ 50,000 hours. Relying on localized service outlets, the response time for common spare parts shall be ≤ 7 days. Operation training shall be provided to ensure that Southeast Mining's operation and maintenance team can operate independently.

Core Objectives

- Efficiency compliance: The handling capacity of the conveying system shall be stably ≥ 2500 tons per hour, with no transshipment throughout the 8617-meter route, completely replacing the truck transshipment mode;

- Environmental protection compliance: Dust emission shall be controlled within 8mg/m³, and the iron ore loss rate shall be reduced to below 1%;

- Terrain adaptation: The equipment shall smoothly adapt to 7 horizontal curves and undulating mountainous terrain without the need for large-scale mountain leveling;

- Operation and maintenance optimization: The annual failure rate of the equipment shall be ≤ 0.5%. Compared with the traditional mode, the annual maintenance cost shall be reduced by 35%, and the spare part response cycle shall be ≤ 7 days.

Customized Solution Design

Core Equipment

In response to the 8617-meter mountainous curved route and the heavy-load requirement of 2500 tons per hour for iron ore, one set of long-distance curved belt conveyor has been custom-produced for Southeast Mining, with key optimizations focusing on "curve adaptation, heavy-load wear resistance and open-air durability":

- Mountain adaptation design: The "multi-section curve coordination + gradual tension control" technology is adopted to adapt to 7 horizontal curves (turning radius of 1000 meters, maximum turning angle of 36°). ZOOMRY's independently developed "friction self-aligning idler group" (diameter 133mm, adapted to 1200mm belt width) is configured, with radial runout ≤ 0.4mm (better than the national standard of 0.5mm) and water inflow ≤ 95g in the 72-hour immersion test (better than ZOOMRY's standard of 100g), which can automatically correct belt deviation and avoid iron ore scattering at mountain turns; for the undulating mountainous terrain, a "segmented gradual slope" design is adopted (maximum slope ≤ 8°), combined with the ST2500 steel cord Conveyor Belt (tensile strength ≥ 2500N/mm, wear-resistant layer thickness 15mm, specially adapted to the high abrasiveness of iron ore), to ensure no belt slipping during heavy-load conveying. The sealing structure with 120mm overlapping of the conveyor belt further blocks dust emission.

- Multi-point drive: The "4-point distributed drive" design is adopted, equipped with 4 630kW variable-frequency motors (total power 2520kW, protection level IP55), matched with hard-tooth surface reducers (transmission efficiency ≥ 96%). The motors are evenly distributed in different sections of the 8617-meter route to avoid excessive belt tension caused by single-point drive, adapting to the heavy-load conveying requirement of iron ore; the belt speed is set to 4.0m/s, and the feeding amount is adjusted in real time through the PLC-linked feeding system to ensure a stable handling capacity of 2500 tons per hour; the drive drum is made of 40Cr forged material (diameter 630mm), with diamond-shaped rubber coating on the surface (friction coefficient ≥ 0.45, wear resistance increased by 60%), and has undergone ultrasonic flaw detection and tempering stress relief treatment, with no internal cracks and a service life of more than 50,000 hours, to cope with the high abrasiveness of iron ore.

- Durability enhancement: The conveyor frame adopts a hot-dip galvanizing process (rust prevention grade reaching Zn12 level in GB/T 13912-2002), which increases the resistance to rain erosion in mountainous areas by 60%; a detachable transparent PC Rain Cover (inclination angle 15°, adapted to rainwater drainage in mountainous rainy areas) is installed above the conveyor belt, which is convenient for inspection, shields from exposure to the sun and rain, and avoids aging of the conveyor belt; the hydraulic tensioning device is equipped with an oil temperature control system, which can work stably in the temperature difference environment of -10℃ ~ 42℃, and automatically compensates for the thermal expansion and contraction of the belt caused by the day-night temperature difference in mountainous areas, ensuring stable belt tension in the curved and undulating sections.

Supporting Node Equipment

To realize the smooth flow of iron ore from mine trucks to conveyors, two types of equipment independently developed by ZOOMRY are provided as supporting facilities, with parameters accurately matching the core conveyor and adapted to the heavy-load and high-abrasiveness characteristics of iron ore:

- ZRLS-TU1400 wheeled truck unloader: Installed in the raw material receiving area near the mountain crushing area of Southeast Mining, with a belt width of 1400mm and a handling capacity of 200-1000 tons per hour, adapted to the 50-ton dump trucks commonly used by the mining company (dedicated for heavy-load iron ore transportation). The equipment is equipped with 2 hydraulically adjustable ramps (slope 6.7°, in line with the climbing capacity of heavy-load trucks in mountainous areas), allowing trucks to drive directly onto the ramp for unloading without reversing. The bottom of the ramp is equipped with a double-layer rubber sealing skirt to reduce iron ore dust emission during the unloading process; at the same time, it is equipped with a high-frequency vibration feeding device (adapted to the high-density characteristics of iron ore), which can adjust the unloading speed in real time according to the operation status of the conveyor to avoid iron ore accumulation in the receiving area and achieve a matched rhythm of "unloading - conveying".

- ZR series hopper feeder: Installed between the unloader and the conveyor, adopting an enlarged 12cbm receiving hopper (adapted to the intermittent unloading rhythm in mountainous areas and the heavy-load requirement of iron ore), equipped with a 37kW variable-frequency speed-regulating motor, which can adjust the feeding amount in real time (2000-2500 tons per hour) to ensure uniform iron ore flow into the conveyor and avoid overloading or underloading; the inner wall of the hopper is paved with a 15mm thick wear-resistant ceramic liner (specially designed to cope with the high abrasiveness of iron ore), and the top is equipped with a dust cover and a rain edge to reduce dust dispersion and rainwater entry in the open-air mountainous environment, and avoid iron ore caking due to moisture.

Core Components

All key components are independently produced by ZOOMRY, with performance better than national standards and CEMA standards. They are designed to be enhanced for the high abrasiveness of iron ore, providing support for the long-term stable operation of Southeast Mining in mountainous areas:

- Idlers and drums: In addition to the friction self-aligning idlers in the curved sections, high-wear-resistant and low-noise idlers (diameter 133mm) independently developed by ZOOMRY are selected for the straight sections, with a rotational resistance ≤ 2N (better than the national standard of 3N) and an operating noise ≤ 45dB (better than the national standard of 55dB). The surface is treated with a wear-resistant coating, and the water inflow in the 72-hour immersion test is ≤ 95g, adapting to the humid environment and iron ore dust abrasion in mountainous areas; the direction-changing drum is made of 40Cr seamless steel pipe (diameter 500mm), with the surface treated by thermal spraying of tungsten carbide (wear resistance increased by 80%) and an ovality < 1.5mm, ensuring stable operation of the belt in the undulating mountainous route.

- Cleaning and safety components: One set of high-hardness PU cleaning scrapers (adapted to the cleaning of residual iron ore) is installed at each of the head and tail of the conveyor, with a fitting degree of ≥ 98% with the conveyor belt, effectively removing residual iron ore particles on the belt surface and avoiding belt deviation caused by material adhesion; at the same time, "triple safety protection" is equipped - belt deviation switch (automatic alarm when deviation exceeds 5mm), emergency rope break system (shutdown within 0.01 seconds when the steel rope breaks), and overload protection device (automatic power-off when the motor is overloaded), complying with international mining safety regulations; a non-powered dust removal chute (with a built-in air flow buffer chamber, adapted to dust control during iron ore unloading) is installed at the discharge end to further reduce dust emission during the unloading process in mountainous areas.

Project Implementation

Preliminary Survey

ZOOMRY dispatched an 8-person technical team to Southeast Mining in Wuxue, Hubei, and completed three key tasks within 18 days: constructing a 3D topographic model of the 8617-meter route through UAV aerial photography and total station surveying, accurately marking the center positions, turning radii of the 7 horizontal curves and the slope distribution of the undulating mountain sections, optimizing the installation height of the conveyor frame, and avoiding waterlogged areas and soft mountain bodies in the mountainous rainy season (to avoid affecting the safety of heavy-load iron ore conveying); collecting iron ore samples to test fluidity, abrasiveness and moisture content in the laboratory, and determining key parameters such as idler spacing (1.2 meters) and belt tension (22kN) in combination with the characteristics of mountainous conveying (adapted to the high-density characteristics of iron ore); formulating a special open-air equipment protection plan with reference to the local meteorological data of the past 5 years (high temperature, low temperature, rainy season distribution), such as the inclination angle of the rain cover and the setting of the hydraulic oil temperature control threshold.

Production and Manufacturing

All equipment and components are produced in ZOOMRY's Hebei factory, and the entire process is included in the ISO 9001 quality management system and ISO 14001 environmental management system, with enhanced quality control for the high abrasiveness and heavy-load characteristics of iron ore: the drive drum of the long-distance curved belt conveyor must pass a 24-hour static load test with 1.2 times the rated load (designed according to the heavy load of iron ore) to be qualified without deformation; the idlers must undergo a 1500-hour no-load test run (simulating the iron ore dust abrasion environment) to verify the sealing performance and rotational resistance; the ST2500 conveyor belt must complete tension, wear and bending tests (special tests for iron ore abrasion conditions) to ensure adaptation to the heavy-load conveying requirement in mountainous areas. Southeast Mining sent representatives to the factory for acceptance, and all parameters met the contract requirements. In particular, the open-air durability test results (high and low temperature cycles, rain test, strong wind simulation) were excellent, fully adapting to the iron ore conveying environment in mountainous areas.

Installation and Commissioning

ZOOMRY dispatched a 12-person installation team to the site of Southeast Mining, adopting a "modular splicing + section-by-section commissioning" mode to address the difficulties of mountain construction: dividing the 8617-meter conveyor into 43 sections (each 200-210 meters), pre-assembling them in the factory in advance, and only requiring bolt connection and belt vulcanization on site, which greatly reduced the on-site construction volume in mountainous areas (reducing interference with mining production); the installation period was only 45 days (the industry average period is 60 days) and avoided the mountainous rainy season; the commissioning phase was carried out in three steps: first, conducting a no-load test of a single equipment (verifying the operation status of the motor and idler under voltage fluctuations in mountainous areas, adapting to the heavy-load start-up requirement of iron ore), then carrying out the system linkage test of the unloader - feeder - conveyor, and finally conducting a 72-hour full-load test run (simulating high temperature, gust conditions in mountainous areas and continuous iron ore conveying), optimizing the PLC program, so that the handling capacity of the conveyor was stably maintained at 2550 tons per hour, exceeding the required standard of 2500 tons per hour.

Operation and Maintenance Training

A 20-day special training was provided for 10 operation and maintenance personnel of Southeast Mining, with content designed around the characteristics of iron ore conveying equipment in mountainous areas: covering daily inspection of open-air equipment in mountainous areas (idler rotation status, hydraulic oil level, rain cover tightness, mountain landslide risk inspection), common fault handling (belt deviation, motor overload, electrical faults caused by rainwater) and regular maintenance (idler lubrication, scraper replacement, equipment drainage in rainy season); in view of the high abrasiveness of iron ore, additional training on skills such as "idler wear judgment" and "scraper adaptation adjustment" was provided; the training adopted Chinese and English bilingual operation manuals and video cases of iron ore conveying faults in mountainous areas. Relying on ZOOMRY's domestic service outlets, common spare parts can be quickly allocated through regional warehouses with a response time of ≤ 7 days. At the same time, a 24-hour technical hotline is opened to ensure timely response to the operation and maintenance needs of Southeast Mining's mountainous mining area.

Project Results

After the project was put into operation, the equipment operated stably for a long time in the open-air mountainous environment of Southeast Mining, and all indicators exceeded expectations, creating significant value for the mining company:

- Efficiency and production capacity release: The 8617-meter route realizes conveying without transshipment throughout the whole process. The actual handling capacity of the conveyor is stably maintained at 2550 tons per hour, fully matching Southeast Mining's crushing capacity of 2500 tons per hour, and there is no longer iron ore backlog during peak hours; the conveying cycle is shortened from 12 hours in the traditional "conveyor + truck transshipment" mode to 3.4 hours, reducing the production downtime caused by insufficient conveying by about 60 hours per year and indirectly increasing the production capacity value; the smooth adaptation of 7 horizontal curves saves the investment and maintenance costs of 4 transshipment stations, and at the same time avoids the 5.5% iron ore loss in the transshipment link. Based on an annual conveying volume of 20 million tons, the annual loss is reduced by about 1.1 million tons.

- Environmental protection and compliance: The fully sealed design of the system reduces the dust emission from 28mg/m³ to 7.8mg/m³, far exceeding the national standard. Since then, Southeast Mining has not received any environmental complaints from the surrounding area, avoiding the risk of environmental penalties; the iron ore loss rate is reduced from 5.5% to 0.9%, significantly improving the material utilization rate; the design of the rain cover and sealed conveyor belt reduces the iron ore caking rate from 12% to 1.8% in the rainy season, eliminating the need for additional crushing processes, which not only saves energy consumption but also reduces the impact of mountain rainwater on iron ore processing.

- Reliability and mountain adaptation: The core components of the equipment (idlers, drums, motors) have operated for more than 40,000 hours without large-scale replacement. Only regular replacement of the conveyor belt and cleaning scraper is required. The annual maintenance frequency is reduced from 15 times to 4 times, and the maintenance cost is reduced by 42%; even in the mountainous environment with a temperature difference of -10℃ ~ 42℃, strong winds and heavy rains, the annual failure rate of the equipment is only 0.3%, far lower than the target of 0.5%, and there has been no major failure due to extreme weather or mountain terrain; when Southeast Mining plans to upgrade its production capacity for the second time, it only needs to fine-tune the motor power and PLC program to adapt to the new requirement of 2800 tons per hour, and the equipment expandability far exceeds expectations.

- Cost and ecological optimization: Compared with the traditional mode, the civil engineering and equipment investment for 4 transshipment stations is saved, and at the same time, the ecological damage caused by mountain leveling is avoided (in line with the environmental protection requirements of the mining industry); the localized operation and maintenance service shortens the spare part response cycle from 40 days to 7 days, and the annual downtime is reduced from 120 hours to 25 hours, indirectly reducing economic losses.

The person in charge of the project at Hubei Wuxue Southeast Mining said: "What we were most worried about before was the stability of conveying heavy loads of iron ore along the 7 curves in the mountainous area. ZOOMRY's equipment not only runs stably along the 8-kilometer route, but also withstands heavy rains in summer and low temperatures in winter, and has no problem dealing with the high abrasiveness of iron ore. Last time we needed to replace an idler, it was delivered from the local spare part warehouse in 5 days, and our technical team replaced it by ourselves with remote guidance from ZOOMRY's technicians, without delaying production at all. When we expand to other mining areas in the future, we will definitely give priority to ZOOMRY's solutions, after all, the equipment adaptability and service are very in line with the needs of our mining industry."

Core Advantages of ZOOMRY

- Customization capability for mining scenarios: In response to the 7 curves in the mountainous area of Southeast Mining and the heavy-load and high-abrasiveness characteristics of iron ore, relying on the independently developed "curve tension control technology" and "segmented drive design", the full set of solutions was completed in only 3 months. Compared with the design cycle of more than 6 months for international brands, the project implementation time is greatly shortened; at the same time, the equipment protection and dust control structure are optimized in combination with the mountainous climate and mining environmental protection requirements to ensure adaptability and reliability.

- Full-chain equipment coordination advantage: From wheeled truck unloaders, hopper feeders to long-distance curved belt conveyors, the full range of equipment is independently developed by ZOOMRY, with seamlessly matched parameters (such as the accurate coordination between unloading speed and feeding amount, the adaptation between the conveyor and the slope of the mountainous terrain, and the matching between the wear-resistant design of components and the characteristics of iron ore), avoiding compatibility problems of equipment from different brands; core components are independently produced, with performance better than national standards and CEMA standards, ensuring the overall reliability of the system.

- Localized operation and maintenance service guarantee: Relying on the extensive domestic service outlets and spare part warehouses, the response time for common spare parts is within 7 days. The 24-hour multilingual technical hotline quickly solves the operation and maintenance problems of Southeast Mining's mountainous mining area, completely getting rid of the long wait for imported spare parts, and is especially suitable for the operation and maintenance needs of mining areas in inconvenient transportation areas.

ZOOMRY

ZOOMRY