Bintulu Port in Malaysia, a major bulk cargo hub in Southeast Asia located along the coast of Sarawak State, handles over 1.5 million tons of Palm Kernel Expeller (PKE) and Palm Kernel Shell (PKS) annually—60% of the PKE is shipped to China, and 40% of the PKS is supplied to India, making it the "lifeline" for the export of Malaysia’s palm oil industry. The port’s dry bulk berth is 245 meters long with a water depth of 12.5 meters at the berth front, capable of accommodating 40,000 DWT (Deadweight Tonnage) ships. However, its outdated ship loading equipment has long been plagued by issues:

On one hand, material characteristics create efficiency bottlenecks. PKE contains 12%-15% oil and easily adheres to the ship loader belt at temperatures above 30°C. Manual cleaning with scrapers is required after each operation, taking over 3 hours per shift. PKS particles have a hardness of 60 HB, and the dust emission rate exceeds 15% when they fall—this not only contaminates equipment components but also limits the loading and unloading efficiency of traditional ship loaders to just 750 tons per hour. A 40,000 DWT bulk carrier takes 38 hours to load and unload, far exceeding the customer’s expected cycle of 24 hours. On the other hand, the tropical environment accelerates equipment wear. The port has an annual average temperature of 30-35°C and humidity of 85%; high humidity and salt spray cause the annual corrosion rate of the existing equipment’s metal structure to reach 0.3 mm, requiring frame component replacement in less than 3 years. Electrical control cabinets also suffer from 15 failures per year on average due to moisture intrusion, with each shutdown for repair delaying operations by at least 8 hours—seriously disrupting the export rhythm during the palm oil peak season (June-October annually). Furthermore, there is urgent pressure to comply with environmental regulations. In 2024, Malaysia’s Ministry of Environment issued the New Environmental Regulations for Port Bulk Cargo Operations, requiring the dust concentration in bulk cargo operation areas to be ≤ 10 mg/m³. However, the existing equipment lacks dedicated dust removal devices, resulting in a common dust concentration of 18 mg/m³ in operation areas. Failure to upgrade the equipment will lead to a monthly fine of 200,000 Malaysian Ringgit (MYR).

Project Requirements

Combining the characteristics of palm by-products and the port’s actual conditions, Bintulu Port Operations Group has defined clear requirement boundaries for the new equipment, ensuring it "improves efficiency, resists corrosion, meets standards, and is implementable":

- Throughput Requirement: The rated handling capacity of a single ship loader shall be ≥ 1,200 tons per hour, covering two types of ships: barges (100-5,000 tons) and bulk carriers (10,000-35,000 tons). The loading and unloading cycle for 40,000 DWT ships must be ≤ 24 hours to adapt to the port’s peak-season operation volume of 3 ships per day on average.

- Quality Compliance: The equipment shall operate continuously at a high temperature of 35°C and high humidity of 85%. The corrosion resistance grade of the metal structure shall meet Class C5-M of the ISO 12944 standard; the electrical system’s protection class shall be ≥ IP66; and the mold resistance grade shall be Grade 0 (no mold growth).

- Environmental Compliance: Dust control devices shall keep the concentration in the operation area ≤ 8 mg/m³ (stricter than the national standard), and the noise level shall be ≤ 75 dB. Meanwhile, the equipment shall integrate functions such as belt deviation protection, wire rope breakage locking, and emergency shutdown, complying with the requirements of Malaysia’s Port Operation Environmental Protection Code.

- Delivery Cycle: The equipment shall be disassembled into 40”HQ container specifications, with a sea freight + land transportation cycle ≤ 30 days and on-site assembly ≤ 20 days. Zoomry Heavy Industry shall provide English training, ensure the supply of key components within ≤ 7 days, and complete fault repair within ≤ 24 hours.

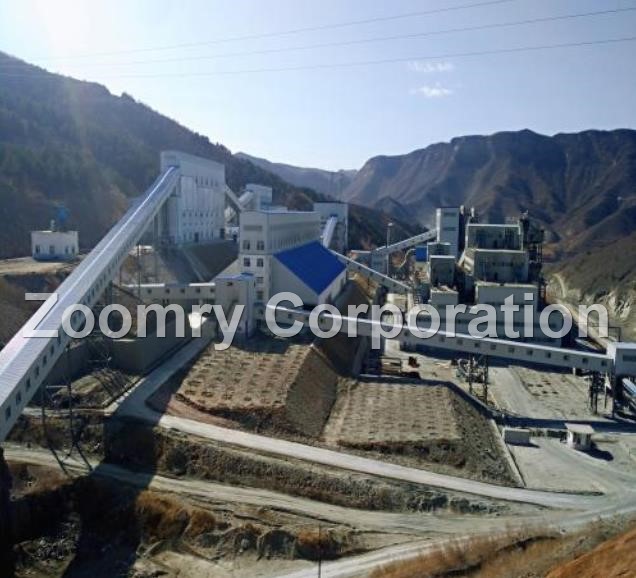

Customized Solution by Zoomry Heavy Industry

To meet the customer’s needs, Zoomry Heavy Industry established a 10-person special team consisting of experts in material engineering, hydraulic systems, and environmental technology. With ZRSL-45 (for barges) and ZRSL-50 (for bulk carriers) mobile ship loaders as the core, the team optimized the equipment for tropical scenarios from three aspects—equipment structure, core components, and intelligent control—forming a closed-loop solution.

Core Equipment Configuration

- Ship Type Coverage: The ZRSL-45 is suitable for 100-5,000 ton barges (clearance height 0-3 meters), and the ZRSL-50 for 10,000-35,000 ton bulk carriers (clearance height 4-8 meters). Both models feature radial adjustment (maximum angle ±30°), telescopic operation (8-meter telescopic section for ZRSL-45, 12-meter telescopic section for ZRSL-50), and luffing (pitching angle -5°~25°), enabling coverage of the entire ship hatch without the need for forklift-assisted adjustment.

- Handling Efficiency: The rated handling capacity of a single unit is 1,200 tons per hour, with a peak capacity of 1,500 tons per hour. Calculated based on 24-hour operation, the daily average handling capacity of one unit reaches 28,800 tons. Two units can meet the 21-hour loading and unloading requirement for 40,000 DWT ships, far exceeding the customer’s 24-hour cycle requirement.

- Transportation and Assembly: The equipment is disassembled into 5 modules of 40”HQ containers, with on-site assembly taking only 16 days—20% shorter than the customer’s requirement—reducing port operation downtime.

PKE/PKS Material Adaptation

- Cleaning System: Adopts a "dual PU cleaner + high-frequency vibration device" configuration. The front PU cleaner fits closely to the belt surface, removing 90% of PKE residues; the rear PU cleaner handles residues on the return section of the belt; an additionally installed 20Hz high-frequency vibration device shakes off PKE residues in the belt grooves through micro-vibration of the belt, resulting in a final residue rate of ≤ 0.3% and completely eliminating manual cleaning.

- Dust Control: The primary stage uses a "non-powered dust collection chute" with 3 layers of guide plates inclined at 30°, reducing the falling speed of PKS from 5 m/s to 2 m/s to minimize air disturbance. The secondary stage is equipped with a pulse bag filter (filter area 150 m²), achieving a 99.6% capture rate for dust particles larger than 0.5 μm. The actual measured concentration in the operation area is 7.2 mg/m³, meeting the ≤ 8 mg/m³ requirement.

- Material Protection Design: Conveying parameters are adjusted based on the characteristics of PKE/PKS. For PKE conveying, the belt speed is set to 2.2 m/s and the chute drop to 2.5 meters to avoid compaction and caking. For PKS conveying, the belt speed is 2.5 m/s, and the inner wall of the chute is lined with 5 mm thick rubber to reduce the breakage rate (controlled within 1%), ensuring the quality of exported materials.

Environmental Protection

- Anti-Corrosion Upgrade: The equipment frame is made of Q355ND weathering steel. After Sa2.5-level sandblasting for rust removal, three layers of fluorocarbon coating (dry film thickness 220 μm) are applied, achieving a salt spray resistance of 5,000 hours. Key bolts are made of 316L stainless steel to avoid electrochemical corrosion, and the annual corrosion rate of the metal structure is expected to drop to 0.05 mm.

- Electrical Moisture Protection: The control cabinet is equipped with an industrial air conditioner (cooling capacity 5 kW) and a dehumidifier (dehumidification capacity 1.2 L/h), stabilizing the internal temperature at 25±3°C and humidity at ≤ 55%. The PLC uses the Siemens S7-1500 tropical model (withstanding high temperatures of 70°C), and motors and sensors all have IP66 protection. Cable joints are filled with waterproof sealant to prevent moisture intrusion.

- High-Temperature Resistance of Hydraulic System: Grade 46 high-temperature anti-wear hydraulic oil (applicable temperature range -10~80°C) is used. The oil tank is equipped with a dual-circuit cooling system—air cooling is used when the oil temperature is ≤ 60°C, and it automatically switches to water cooling when the temperature exceeds 60°C—ensuring the hydraulic oil viscosity remains stable at 150-200 cSt and avoiding power reduction caused by high temperatures.

Safety and Intelligent Control

- Safety Protection: Equipped with belt deviation switches (automatic adjustment when deviation exceeds 5 mm), dual mechanical limits for wire rope breakage, and emergency pull-cord switches (one every 10 meters). The hydraulic winches have an automatic locking function with a response time of 0.01 seconds, enabling instant shutdown in extreme conditions.

- Bilingual Intelligent Control: A 10-inch touchscreen HMI supports English/Malay language switching, enabling three operating modes: PLC full automatic, remote (within 50 meters), and manual. In full automatic mode, two programs—"uniform loading" and "fast loading"—are preset, and real-time data such as handling capacity, temperature, and fault codes are uploaded to the port management platform, realizing "unmanned operation + remote monitoring".

Project Implementation

Adhering to the principles of "compliance, efficiency, and safety", Zoomry Heavy Industry connected all process links to ensure the successful commissioning of the equipment at Bintulu Port.

Design and Production

- Compliance-Oriented Design: SolidWorks 3D modeling software was used to complete the overall equipment design, with a focus on conducting high-temperature finite element analysis of the telescopic boom at 35°C (maximum deformation ≤ 0.4 mm). The electrical system was designed in accordance with SIRIM certification requirements, and the MS IEC 60335 safety report was submitted, obtaining Malaysia’s import permit within 25 days.

- Core components (idler rollers, drums, hydraulic winches) were produced at the Zaoqiang (Hebei) base in accordance with the ISO 9001 standard:

- 10% of each batch of idler rollers was sampled for a 72-hour continuous operation test (rotational resistance ≤ 2 N);

- Drums were made of 40Cr forged material (diameter ≥ 200 mm), processed via CNC four-roll rounding (ovality < 1.5 mm), and subjected to ultrasonic testing after welding;

- The locking response time of hydraulic winches was tested to ensure it was ≤ 0.01 seconds.

Logistics and On-Site Installation

- Zoomry Heavy Industry dispatched 2 engineers to the site to cooperate with the local team, advancing operations during the 3 hours of daily low tide (when the port’s water level is stable):

- First, the chassis levelness was calibrated (error ≤ 0.1%), then the telescopic boom and hydraulic pipelines were installed (no leakage detected in the 1.2x rated pressure test);

- The negative pressure of the dust control system was commissioned to -5.5 kPa, and the braking distance of the travel mechanism on slippery roads was verified (≤ 3 meters);

- Bilingual Training: A 12-day training session was conducted for 15 operators, covering "tropical maintenance key points (daily inspection of hydraulic oil temperature, cleaning of air filters) and fault code interpretation", with supporting bilingual operation manuals provided.

Multi-Dimensional Acceptance

- Efficiency Test: Loading and unloading of a 30,000 DWT bulk carrier took only 20.5 hours. The average handling capacity of the ZRSL-50 was 1,280 tons per hour, 6.7% higher than the rated value.

- Environmental Test: Third-party testing showed the dust concentration in the operation area was 7.2 mg/m³ and the noise level was 66 dB, both lower than the standards.

- Environmental Adaptation Test: Continuous operation was simulated for 96 hours at 35°C and 85% humidity, with no equipment failures and the electrical cabinet temperature remaining at 26°C.

- Safety Test: When belt deviation and power failure scenarios were triggered, the equipment locked within 0.008 seconds, confirming the effectiveness of the safety functions.

Project Achievements

Capacity Improvement

- The berth turnover rate increased by 45%: The loading and unloading cycle per ship was reduced from 38 hours to 20.5 hours, allowing the port to handle 4 more bulk carriers per month. The export volume of PKE/PKS increased from 120,000 tons per month to 150,000 tons, even reaching 180,000 tons in the peak month of October—a year-on-year increase of 25%.

- The equipment availability rate reached 99%: Downtime due to PKE adhesion was reduced from 3 hours per day to 0.3 hours. There was only 1 failure in the tropical environment (a loose sensor, repaired within 2 hours), far exceeding the customer’s expected 95% availability rate.

Operation and Maintenance Cost Reduction

- Environmental Cost Savings: After meeting dust standards, annual fines of 800,000 MYR (calculated at 200,000 MYR per month) were avoided, and labor costs for dust cleaning were reduced by 15,000 MYR per month.

- Spare Parts and Maintenance Cost Reduction of 35%: The service life of idler rollers and drums exceeds 50,000 hours, with no core components replaced in 6 months. Compared with the old equipment (which required idler roller replacement every 2 years), 180,000 MYR in spare parts costs was saved. The anti-corrosion design extended the maintenance cycle from 3 months to 6 months, reducing maintenance man-hours by 50%.

A leader of Bintulu Port Operations Group stated: "As someone in charge of equipment technology, my biggest initial concern was ‘technical adaptability’. The high-humidity and salt-spray environment at Bintulu Port causes severe corrosion to equipment metal structures and electrical components—previous equipment required major overhauls in less than two years. Moreover, we had never found a complete solution to the problems of PKE adhering to belts and PKS wearing down components. However, Zoomry’s mobile ship loaders have greatly changed my perception: The anti-corrosion coating on the equipment frame shows no rust at all after half a year; the dehumidification device in the electrical cabinet is very effective—even when humidity exceeds 90% during the rainy season, there has not been a single short-circuit failure. The idler rollers and drums are really durable—based on their current wear condition, a 50,000-hour service life is completely feasible, eliminating the need for frequent shutdowns for component replacement. What’s more convenient is the equipment’s modular design—once we needed to adjust the operation position, the disassembly and reinstallation took 3 days faster than expected, without delaying the shipping schedule at all. When we expand new berths in the future, we will give priority to purchasing belt conveyors from Zoomry Heavy Industry to deepen our cooperation."

ZOOMRY

ZOOMRY