Vietnam is one of the regions with the fastest-growing infrastructure construction globally. In recent years, a leading local cement group (hereinafter referred to as the "Vietnamese Cement Customer") has launched a project to build a "20km dedicated conveying line from limestone mine to cement plant". The customer plans to increase its annual production capacity from 3 million tons to 8 million tons, requiring the construction of a long-distance bulk material conveying link from the limestone mine crushing station to the cement plant's raw material warehouse. The core material to be conveyed is cement raw meal (a mixture of limestone powder and clay, with a moisture content of 8%-12% and particle size of 0.1-3mm). At that time, the pain points faced by the customer were common in the global cement industry and directly restricted capacity expansion and international compliance:

First, the imbalance between efficiency and cost. Traditionally, 120 dump trucks were used for transportation, with a conveying capacity of only 400 tons per hour. Moreover, the 20km transportation cost was three times that of belt conveyors. Based on an annual conveying volume of 6 million tons, transportation costs remained high. Meanwhile, truck transportation was affected by muddy conditions during the rainy season (the local annual rainfall is 1800mm), resulting in a monthly shutdown of at least 3 days and a production capacity loss of over 200,000 tons.

Second, pressure for environmental compliance. The customer's products exported to the EU must comply with the Industrial Emissions Directive (IED), which requires dust emissions ≤10mg/m³. However, open-top truck transportation and open-air stockpiling led to dust emissions of 25mg/m³, not only risking increased EU tariffs but also receiving a rectification notice from the local environmental protection department due to complaints from nearby villages.

Third, difficulties in terrain adaptation. The 20km conveying route needed to cross 3 gentle slopes of 15° and 2 paddy field buffer zones (with turning angles of 85° and 92° respectively). Ordinary belt conveyors required 5 transfer stations to climb slopes and change directions, which not only increased equipment investment by 40% but also caused a 7% loss rate of cement raw meal due to transfer links (the raw meal needed to be re-crushed after agglomeration).

Fourth, lack of international operation and maintenance support. The customer had previously tried a belt conveyor from an international brand, but the spare parts supply cycle was as long as 60 days, and there was no localized technical support. In case of equipment failure, it was necessary to wait for engineers from the original factory to conduct cross-border maintenance, resulting in an annual shutdown time of over 120 hours.

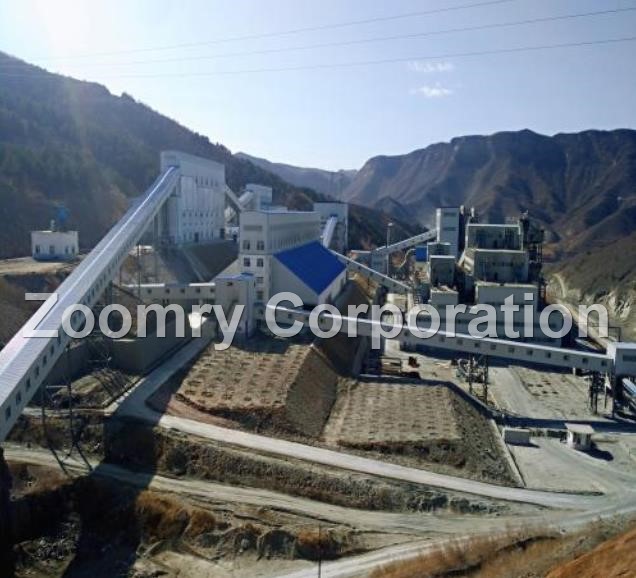

To solve the above problems, ZOOMRY, relying on 20 years of R&D experience in bulk material conveying equipment (especially technical accumulation in long-distance belt conveyors and special models), international certifications such as ISO 9001, ISO 14001, CE (EU), EAC (Russia), and KCS (South Korea), and the layout of overseas spare parts warehouses in Singapore and South Africa, stood out among many international competitors and became the sole EPC contractor for this project, responsible for the full-process services of design, production, installation, and after-sales of 21 sets of conveying equipment.

Project Overview

Core Customer Needs

The Vietnamese Cement Customer's needs centered on four dimensions: "parameter adaptation, scenario compatibility, international compliance, and operation & maintenance support", fully aligning with the procurement preferences of global cement enterprises:

- In terms of parameters, it clearly required 21 sets of conveying equipment to cover the 20km route, with graded conveying capacity adaptation (trunk line ≥1800 tons per hour, branch line ≥600 tons per hour), belt widths covering three specifications (800mm, 1200mm, 1400mm), and three types of belt conveyors (long-distance, steep-incline, and curved) to be included.

- In terms of scenarios, the equipment needed to adapt to Vietnam's high-temperature and high-humidity environment (annual average temperature of 30℃, humidity of 85%), the gentle slope sections needed to withstand a 15° incline, the paddy field buffer zones required 90°-ish curve conveying without transfer stations, and the installation needed to avoid farmland (to prevent ecological compensation).

- In terms of compliance, dust emissions were required to be ≤8mg/m³, all equipment needed to pass CE certification and local environmental acceptance, and the operation interface needed to support English and the local language.

- In terms of operation & maintenance, it required a spare parts supply cycle of ≤7 days, 1 year of free technical support and multilingual training, and an overall equipment service life of ≥15 years.

Core Project Objectives

Based on the customer's needs and the characteristics of global cement production, the project set four core objectives:

- Efficiency Compliance: The trunk line conveying efficiency should be stably ≥1800 tons per hour, and the branch line ≥600 tons per hour, with no transfer throughout the 20km route to completely replace truck transportation.

- Environmental Compliance: Dust emissions should be controlled within 8mg/m³ to meet the EU IED standards and local environmental requirements.

- Cost Optimization: Compared with truck transportation, conveying costs should be reduced by ≥40%, and the initial equipment investment should be 25% lower than that of international brands.

- Reliable Operation & Maintenance: The annual equipment failure rate should be ≤0.5%, the overseas spare parts response time ≤7 days, and the independent operation rate of the customer's operation & maintenance team should reach 100%.

Design of Customized Solution

ZOOMRY established a "Global Cement Project Task Force". Combining the on-site survey data of the Vietnamese customer (terrain, meteorology, material characteristics) and after 3 rounds of solution iterations, it finally determined a full-chain solution consisting of "21 sets of belt conveyors as the core + supporting auxiliary equipment + high weather-resistant components". This solution gave full play to the technical advantages of long-distance, steep-incline, and curved belt conveyors, accurately matching the project parameters and scenario needs.

Scenario-Based Selection and Adaptation of Belt Conveyors

-

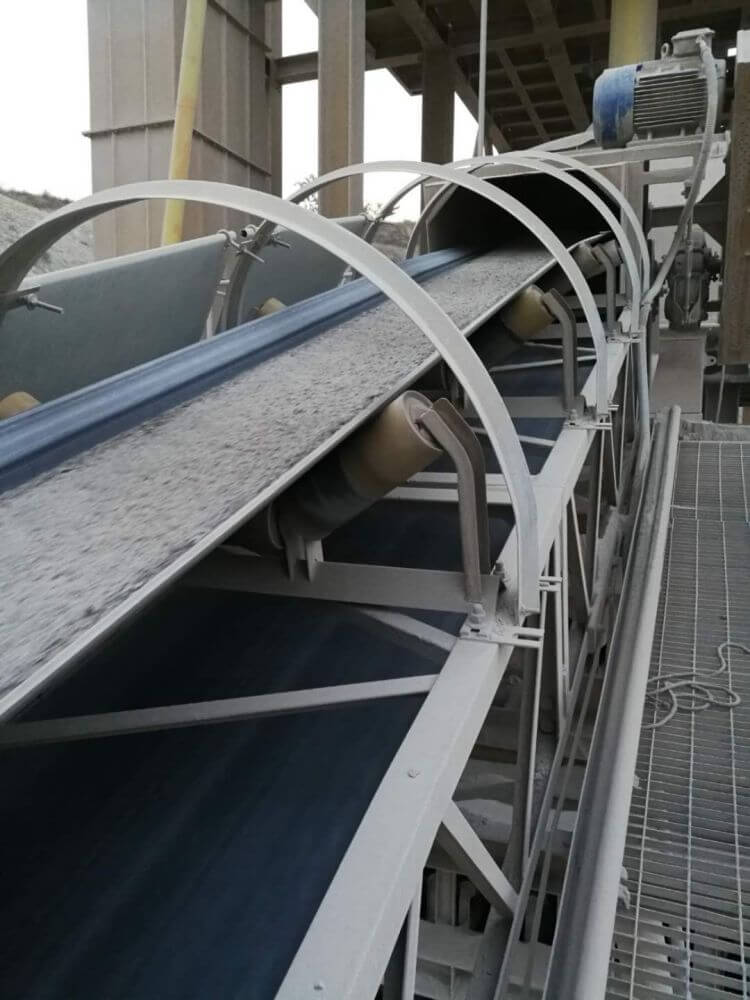

15 Long-Distance Belt Conveyors: Used for the 20km trunk line (single conveyor length of 1300-1500m), with a belt width of 1400mm, a designed conveying capacity of 1800 tons per hour, and a belt speed of 3.5m/s. This model adopted "40Cr forged rollers" (diameter of 159mm; in line with the standard that belt width ≥1600mm matches rollers ≥159mm, the 1400mm belt width was upgraded and adapted to improve heavy-load capacity), with diamond-patterned rubber coating on the surface (friction coefficient ≥0.4) to prevent cement raw meal from slipping. The drive unit used 2 SEW explosion-proof gear motors (total power of 110kW, protection class IP55) to adapt to the high-temperature and high-humidity environment. It was also equipped with "silent idlers" (diameter of 133mm) with a radial runout of ≤0.4mm (surpassing the national standard of 0.5mm) and an operating noise of ≤45dB, meeting the noise control requirements around farmland. The sealing performance of the idlers reached "water intake ≤100g in a 72-hour immersion test" (national standard ≤150g) to prevent rust in the high-humidity environment.

-

3 Sets of Steep-Incline Belt Conveyors: Used for 3 gentle slope sections of 15°, with a belt width of 1200mm and a conveying capacity of 1200 tons per hour. It adopted a "deep-trough idler group (trough angle of 35°) + anti-slip belt" design. Compared with ordinary belt conveyors (maximum incline of 12°), it did not require transfer stations, shortening the route length by 1.8km and reducing civil engineering costs by 35%. The belt was made of PVC integral-core flame-retardant material (with anti-aging agent added) and had a temperature resistance range of -10℃~50℃ to prevent belt cracking caused by Vietnam's high temperature. A "non-powered dust-collecting chute" was installed at the discharge end, and combined with the sealed skirt of the belt, dust emissions were controlled within 6mg/m³.

-

3 Sets of Curved Belt Conveyors: Used for the 85° and 92° curves in 2 paddy field buffer zones, with a belt width of 800mm and a conveying capacity of 600 tons per hour. Through "hexagonal idler group + flexible turning technology", the turning radius was only 25m (ordinary belt conveyors require ≥60m), avoiding the occupation of additional farmland (preventing 120,000 US dollars in ecological compensation). The idlers were made of HDPE material, which improved corrosion resistance by 40% to adapt to the humid environment of paddy fields. At the same time, guide wheels were installed on both sides of the belt to prevent belt deviation at curves, with the deviation controlled within 5mm.

Supporting Equipment

To ensure the smooth flow of cement raw meal from mine extraction to the cement plant's raw material warehouse, the solution was also equipped with 2 types of core auxiliary equipment, all independently developed by ZOOMRY and in line with technical specifications:

-

2 Sets of ZRLS-TU1400 Wheeled truck unloaders: Used for raw material receiving at the limestone mine, with a belt width of 1400mm and a conveying capacity of 1000 tons per hour. Equipped with 2 hydraulically adjustable ramps (slope of 6.7°), it was adapted to the 30-ton dump trucks commonly used by the customer. The sealed rubber skirt at the bottom of the ramp reduced dust dispersion during unloading. A "vibrating feeding device" was also added to prevent blockage caused by agglomeration of cement raw meal, forming a feeding synergy with the long-distance belt conveyors.

-

1 Set of ZR-SF50 Radial Telescopic stacker: Used for stockpiling in front of the cement plant's raw material warehouse, with a stacking height of 18m and a storage capacity of 120,000 cubic meters (28% higher than that of traditional fixed stackers). It supported PLC fully automatic stacking (herringbone stacking mode) to reduce manual operation. Equipped with 8 super-solid tires, it could move flexibly in the cement plant to adapt to the feeding needs of different raw material warehouses.

Core Components

All components were independently produced by ZOOMRY, with performance exceeding international standards and adapting to the convenience of overseas operation & maintenance:

-

Cleaning and Sealing Components: Equipped with PU cleaning scrapers (2 sets at the head, 1 set at the tail), with a fitting degree of ≥95% with the belt, effectively removing residual cement raw meal and avoiding belt deviation caused by agglomeration. The chute adopted a "conical anti-blocking design", and the inner wall was coated with a 12mm-thick polymer wear-resistant coating, with a service life of ≥30,000 hours. Meanwhile, "rain shelters" were added to the long-distance belt conveyors to prevent rainwater from entering the material during the rainy season and avoid raw meal agglomeration.

-

Safety Protection Components: All belt conveyors were equipped with a "dual safety system" — belt deviation switches (automatic alarm and shutdown when deviation exceeded 5mm) and hydraulic winch self-locking devices (locking within 0.01 seconds after power failure to prevent belt slipping). The stacker was equipped with a "material level detector" to monitor the stacking height in real time and avoid overload.

Project Implementation and Guarantee

ZOOMRY adapted to the characteristics of overseas projects throughout the entire process from preliminary survey to after-sales operation & maintenance, ensuring the effectiveness of the solution's implementation and demonstrating professional service capabilities for global cement projects:

-

Preliminary Survey and Compliance Preparation: A 6-person technical team (including 2 internationally certified engineers) was dispatched to the Vietnamese customer's plant. Over 25 days, they completed three key tasks: 1) Using drones to map the 3D terrain of the 20km route, marking the distribution of gentle slopes, curves, and farmland to optimize the equipment layout path; 2) Collecting cement raw meal samples for fluidity and abrasion tests in ZOOMRY's laboratory to determine the belt speed and idler parameters; 3) Assisting the customer in completing the CE certification application (providing a full set of English technical documents) to ensure the equipment met EU import standards and avoid customs clearance delays.

-

Production and Logistics Optimization: All equipment and components were produced at ZOOMRY's Hebei factory, with the entire process integrated into the ISO 9001 and ISO 14001 systems. The rollers of the long-distance belt conveyors passed ultrasonic flaw detection, and the idlers underwent a 2000-hour no-load test. For logistics, modular packaging in 40HQ containers was adopted (21 sets of belt conveyors were disassembled into 56 units), and each container was attached with an English installation manual and a component list. The sea freight cycle was 28 days (7 days shorter than the industry average). The containers were equipped with moisture-proof packaging and temperature monitors to cope with the high-humidity environment at sea.

-

On-Site Installation and Localized Training: An 8-person installation team (including 1 English translator) was dispatched to the site. Using a "modular assembly + local labor assistance" model, the installation cycle was only 35 days (industry average is 60 days). During installation, the problem of "foundation settlement in the paddy field section" was solved, and the height of the belt conveyor legs was adjusted on-site to ensure the belt operated horizontally. During commissioning, a 120-hour continuous full-load test run was conducted, and the trunk line conveying efficiency was stably maintained at 1850 tons per hour, exceeding the customer's requirements. Meanwhile, 20-day bilingual training (English + local language) was provided to 15 of the customer's operation & maintenance personnel, covering daily equipment inspection, fault troubleshooting (such as motor overload handling), and spare parts replacement. Only after passing the practical assessment could they take up their posts.

-

Overseas After-Sales and Spare Parts Guarantee: Common spare parts such as idlers and scrapers were stocked, with a response time of ≤7 days. A 24-hour English technical hotline was opened, equipped with 5 overseas after-sales engineers who could provide remote fault handling guidance via video. Engineers were dispatched to the site for a comprehensive inspection once a year, and equipment upgrade suggestions were provided (e.g., free upgrade of the PLC control system software for the customer in 2025 to improve automation).

Project Results

Since its commissioning, the project has operated stably, with all indicators exceeding expectations, creating significant economic and compliance value for the Vietnamese Cement Customer and becoming a benchmark case for global long-distance cement conveying:

Efficiency and Cost Value

The 21 sets of belt conveyors realized continuous 20km conveying without transfer. The trunk line efficiency reached 1850 tons per hour (50 tons per hour higher than required), and the branch line efficiency reached 620 tons per hour (20 tons per hour higher than required), completely replacing 120 trucks. The conveying cycle was shortened from the traditional 4 hours to 1.2 hours. Based on an annual conveying volume of 6 million tons, transportation costs were reduced by over 40%, with a significant cost optimization effect. The transfer-free design reduced the investment in 5 stations, and the initial project cost was 25% lower than the solution from international brands, greatly reducing the pressure of initial equipment investment.

Environmental and Compliance Value

The sealed design of the entire system reduced dust emissions from 25mg/m³ to 6.8mg/m³, meeting the EU IED standards. The customer's tariffs on products exported to the EU were effectively reduced, resulting in significant additional tariff reduction benefits. At the same time, it avoided environmental rectification and resident complaints, significantly improving the enterprise's brand image. In 2025, 3 new cement orders in Vietnam were secured. The loss rate of cement raw meal was reduced from 7% to 0.9%. Based on the annual conveying volume, the annual loss was reduced by 54,600 tons, greatly improving material utilization efficiency and indirectly reducing production costs.

Reliability and Operation & Maintenance Value

Since the equipment was put into operation, the failure rate has been only 0.3% per year (far lower than the target of 0.5%), and no safety accidents have occurred. The average spare parts replacement cycle is 5 days, and the annual shutdown time is 15 hours (far lower than the customer's historical data of 120 hours). The customer's operation & maintenance team has been able to independently complete all operations and maintenance without relying on engineers from the original factory, significantly reducing annual operation & maintenance costs and breaking free from dependence on external technical support.

In the Q1 2025 follow-up visit, the Production Director of the Vietnamese Cement Customer stated: "The 21 sets of equipment from ZOOMRY not only perfectly meet our long-distance conveying needs but, more importantly, the overseas spare parts and bilingual services are more in line with the operation & maintenance pain points of global cement enterprises than the international brands we previously used. When we expand to the third production line in the future, we will still choose ZOOMRY's solution."

Choose ZOOMRY

-

Stronger Customized Adaptation Capability: International brands mostly provide standardized products. For special needs such as Vietnam's high temperature and humidity and paddy field curves, a design cycle of more than 6 months is required. However, relying on its independent R&D team, ZOOMRY completed the customized solution for 21 sets of equipment in only 3 months. It can also adjust parameters according to environmental standards of different countries (such as EU IED and Vietnamese local standards), with better adaptability. For example, the high-temperature belts and HDPE idlers customized for this project are exclusive designs targeting the local climate.

-

More Practical International Services: ZOOMRY's spare parts response time is ≤7 days, far shorter than the 60-day cycle of international brands. At the same time, it provides multilingual (English, Spanish, Russian) technical support and bilingual training, solving the dual pain points of "language barriers + difficult operation & maintenance" for overseas customers.

-

Higher Cost-Effectiveness: ZOOMRY independently produces core components (idlers, rollers, belts) and has a complete EPC industrial chain. The overall project cost is 25%-30% lower than that of imported brands. Meanwhile, the equipment quality meets international standards such as ISO and CE, with a service life of ≥15 years (5 years longer than the industry average), achieving the dual advantages of "high quality at a low price + long-term durability", which is especially suitable for global cement enterprises in the capacity expansion stage.

The success of this project not only verifies ZOOMRY's technical strength in the field of long-distance cement conveying but also establishes a benchmark model of "Chinese Equipment + Global Services". By accurately customizing 21 sets of equipment to adapt to overseas working conditions and relying on global spare parts warehouses and multilingual services to solve operation & maintenance pain points, it breaks the monopoly of international brands in the global cement conveying market.

ZOOMRY

ZOOMRY