Integrating the full-process intelligent protection of "monitoring-triggering-braking-locking", it achieves stable braking of 0.2-0.5m/s² through mechanical + hydraulic dual triggering. With graded braking force of 50-1500kN, wide belt width adaptation of 650-2200mm, and full inclination angle coverage of -25°~+32°, it accurately responds to the risks of belt breakage, slipping and deviation. It provides highly reliable safety protection meeting international standards for bulk material transportation in mining, port, power, building materials, chemical and other industries.

Core Product Parameters Table

| Product Series | Rated Braking Force (kN) | Applicable Belt Width (mm) | Trigger Mode | Applicable Inclination Angle | Applicable Belt Strength (N/mm) | Installation Type | Core Applicable Scenarios |

|---|---|---|---|---|---|---|---|

| Light-Load | 50-200 | 650-1200 | Pure Mechanical + Gravity Drive | -15°~+20° | 800-1800 | Fixed/Suspended | Light-load Conveying in Light Industry, Grain Depots, etc. |

| General-Purpose | 300-600 | 800-1800 | Mechanical + Hydraulic Auxiliary | -20°~+28° | 1200-3000 | Fixed/Suspended | Medium-load Conveying in Building Materials, Chemical, Ports |

| Heavy-Load | 800-1500 | 1400-2200 | Mechanical + Hydraulic Auxiliary | -25°~+32° | 1800-4000 | Fixed (Bolt Reinforcement) | Heavy-load Long-distance Conveying in Mining, Power Plants |

Core Advantages of Belt Broken Protective Device

Full-Scenario Seamless Adaptation

Covering the full load range from light to heavy load, it has a wide adaptation range of belt width and inclination angle. There is no need to distinguish the operation direction of the conveyor, and it is universally applicable for upward, downward and horizontal conveying. Compatible with ZOOMRY's own and various domestic and foreign belt conveyors, the modular design enables quick matching without large-scale modification of existing equipment, reducing procurement and installation costs.

Stable Operation Under Extreme Working Conditions

The operating temperature ranges from -40℃ to +60℃. The protective structure is optimized for corrosion resistance, dustproofness and moistureproofness, capable of withstanding erosion from high dust in mines, salt spray in ports and corrosive environments in chemical industry. The frame is welded with high-strength steel, passing stress testing and flaw detection, and can withstand long-term heavy-load impact, featuring long design life and low failure rate.

Sufficient Safety Redundancy

The dual-trigger mechanism combines mechanical reliability and hydraulic stability. The braking deceleration is precisely controlled to avoid secondary damage to the belt and material splashing. The capture mechanism contacts the belt evenly, locking firmly without scratching the belt. It can be quickly reset after an accident, reducing downtime.

Technical Features of Belt Broken Protective Device

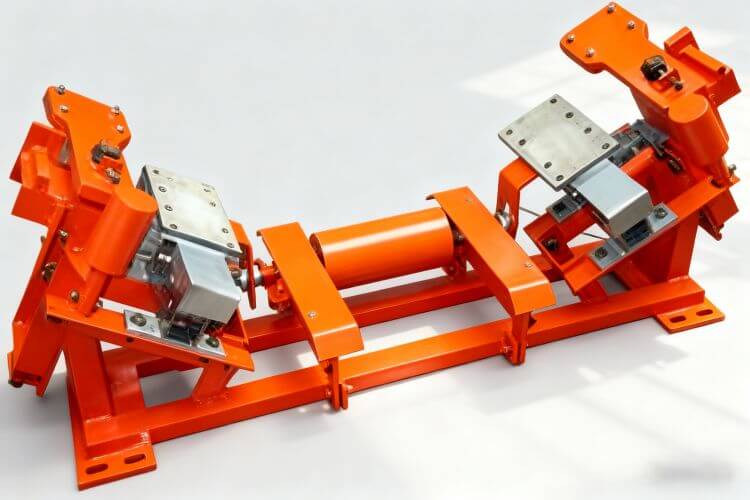

Millisecond-Level Dual-Trigger System

The belt broken protective device integrates mechanical and hydraulic triggering technologies. The mechanical structure quickly captures the belt slack signal, and the hydraulic system synchronously boosts pressure to drive capture, completing braking and locking in milliseconds. Light-load models rely on pure mechanical + gravity drive, requiring no external power supply, and are suitable for powerless and extremely low-temperature scenarios; general-purpose and heavy-load models are equipped with hydraulic assistance, adapting to high-belt-speed and high-throughput heavy-load working conditions, with braking force automatically adapting to different loads.

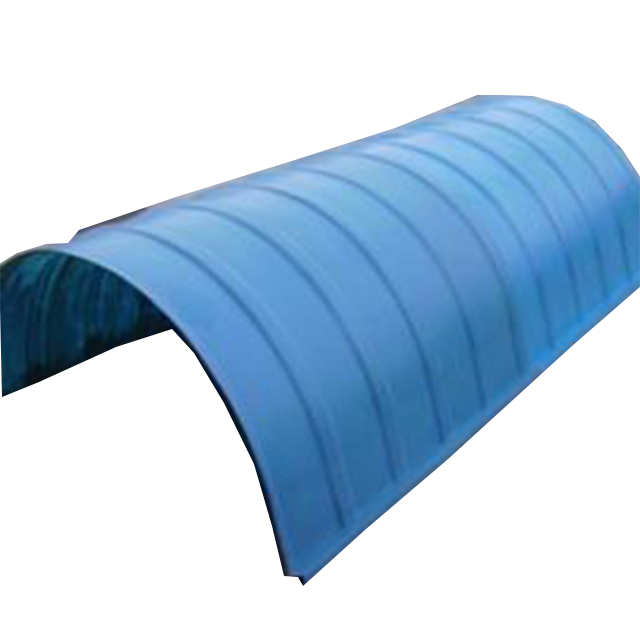

Full-Belt Bidirectional Capture Structure

The equipment adopts a large-area wear-resistant capture mechanism to achieve full-belt bidirectional locking, responding to multiple risks such as belt breakage and deviation simultaneously. There is no need to distinguish the operation direction of the conveyor, and one device meets the protection needs of multiple directions, greatly improving protection flexibility and reducing enterprise equipment investment.

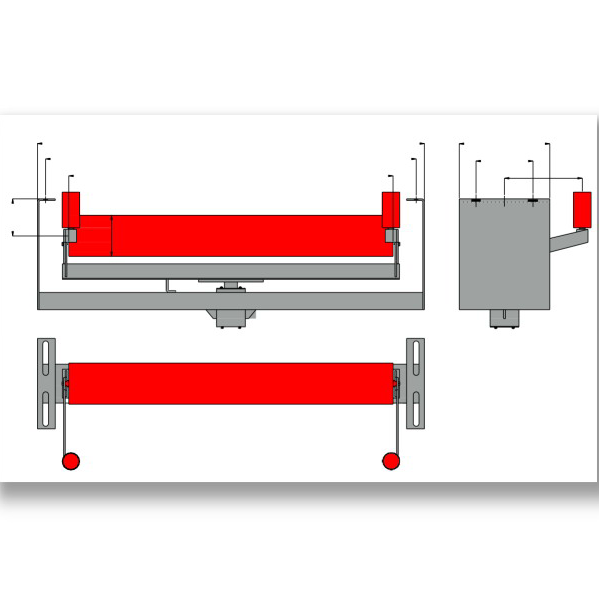

Convenient Installation and Maintenance Design

Two installation methods are available: fixed and suspended (heavy-load models are fixed), adapting to different installation spaces and conveyor structures with simple installation processes. Core components adopt modular design, and wearing parts have strong versatility. Maintenance does not require professional tools and can be operated after simple training, reducing operation and maintenance costs.

Applicable Scenarios of the Product

Mining Industry

Suitable for long-distance and large-inclination conveyors in underground and open-pit mines, providing customized design for explosion protection, dustproofness and moisture resistance. Heavy-load products can handle high-inclination and heavy-load ore conveying, avoiding material falling, equipment damage or roadway safety risks caused by belt breakage, and ensuring continuous production.

Ports and Terminals

The protective coating is optimized for the high humidity and high salt spray environment of maritime climate, adapting to conveyors supporting ship loaders and unloaders. It prevents bulk material spillage and operation interruption caused by belt breakage, ensuring the safe transfer of bulk materials such as coal and ore, and adapting to the large-scale conveying needs of ports.

Power Industry

The heat dissipation and dustproof structures are optimized, suitable for the 24-hour continuous conveying systems of coal, desulfurization gypsum and other materials in power plants. It maintains stable performance under high-temperature and high-dust working conditions, avoiding power generation interruption caused by belt breakage and ensuring continuous energy supply.

Building Materials Industry

Meeting the high-wear and high-load conveying needs of cement, sand, gravel, aggregate and other materials, the capture mechanism adopts wear-resistant materials to extend service life. It accurately protects against belt breakage accidents, avoiding production line stagnation and ensuring the smooth flow of building materials production processes.

Chemical Industry

For corrosive material conveying scenarios, corrosion-resistant materials and sealing designs are adopted to prevent equipment erosion by acid-base environments. It ensures protection performance under special working conditions and guarantees the safety of chemical bulk material transportation.

How to Select the Suitable Belt Broken Protective Device

-

Select by working condition intensity: For light-load working conditions (such as light industry, grain depots), choose the 50-200kN series; for medium-load working conditions (such as building materials, chemical industry), choose the 300-600kN series; for heavy-load working conditions (such as mining, power plants), choose the 800-1500kN series, and accurately match with belt width and belt strength parameters.

-

Select by environmental conditions: For explosion-proof scenarios (such as underground coal mines), choose models with mining product safety mark certification; for corrosive environments (such as ports, chemical industry), select products with high corrosion resistance level; for extremely low-temperature scenarios, prioritize light-load models with pure mechanical drive.

-

Select by installation and supporting needs: For the transformation of existing conveyors, prioritize quick-installation models; for matching ZOOMRY's own hosts, directly select the corresponding adapted models; for remote operation and maintenance scenarios, customized models with condition monitoring function can be chosen.

ZOOMRY Service Support

Full-Process Quality Control

Famous brand raw materials are selected and undergo material and performance testing; advanced processes such as CNC machining and automated welding are adopted in production, with key processes traceable throughout. The product has passed multiple authoritative certifications including ISO9001 quality management system, CE, and mining product safety mark, with technical indicators reaching the international advanced level.

Professional Technology R&D and Customization

The R&D team consists of experts in mechanical design, hydraulic control and automation fields, cooperating with universities and scientific research institutions to track industry technological trends. It can provide one-on-one customized design according to customers' conveyor parameters and working conditions, ensuring the product accurately meets the needs.

Comprehensive Service Support

Provide on-site installation guidance, commissioning and acceptance services to assist in quick put into use; offer training on operation, maintenance and troubleshooting for customers to improve operation and maintenance capabilities. Establish a 7×24 global technical consultation hotline to quickly respond to after-sales issues. Wearing parts are conveniently supplied to ensure long-term stable operation of the equipment.

ZOOMRY

ZOOMRY