ZOOMRY Broken Belt Catcher takes full-belt bidirectional synchronous locking as its core, equipped with a dual-mode trigger system to achieve millisecond-level response of ≤0.3 seconds. With graded braking force of 50-1500kN covering light, medium and heavy loads, it is compatible with full-specification belt widths of 650-2200mm and full inclination angles of -25~+32°, and works seamlessly with ZOOMRY's own and mainstream global brand conveying equipment. It provides a one-stop solution for blind-spot-free, highly reliable and fully compliant belt breakage protection for the mining, port, power plant and building materials industries.

Core Product Parameters Table

| Parameter Name | Light-Load Type | General-Purpose Type | Heavy-Load Type |

|---|---|---|---|

| Rated Braking Force (kN) | 50-200 | 300-600 | 800-1500 |

| Applicable Belt Width (mm) | 650-1200 | 800-1800 | 1400-2200 |

| Belt Strength Adaptation Range (N/mm) | 800-1800 | 1200-3000 | 1800-4000 |

| Capture Method | Full-Belt Bidirectional Capture | Full-Belt Bidirectional Capture | Full-Belt Bidirectional Capture |

| Trigger Mode | Pure Mechanical + Gravity Drive | Mechanical + Hydraulic Assistance | Mechanical + Hydraulic Assistance |

| Applicable Inclination Angle (°) | -15~+20 | -20~+28 | -25~+32 |

| Braking Deceleration (m/s²) | 0.2-0.3 | 0.2-0.4 | 0.3-0.5 |

| Installation Spacing (Upward/Downward Conveying) (m) | 30-80/80-150 | 20-60/50-120 | 10-30/30-80 |

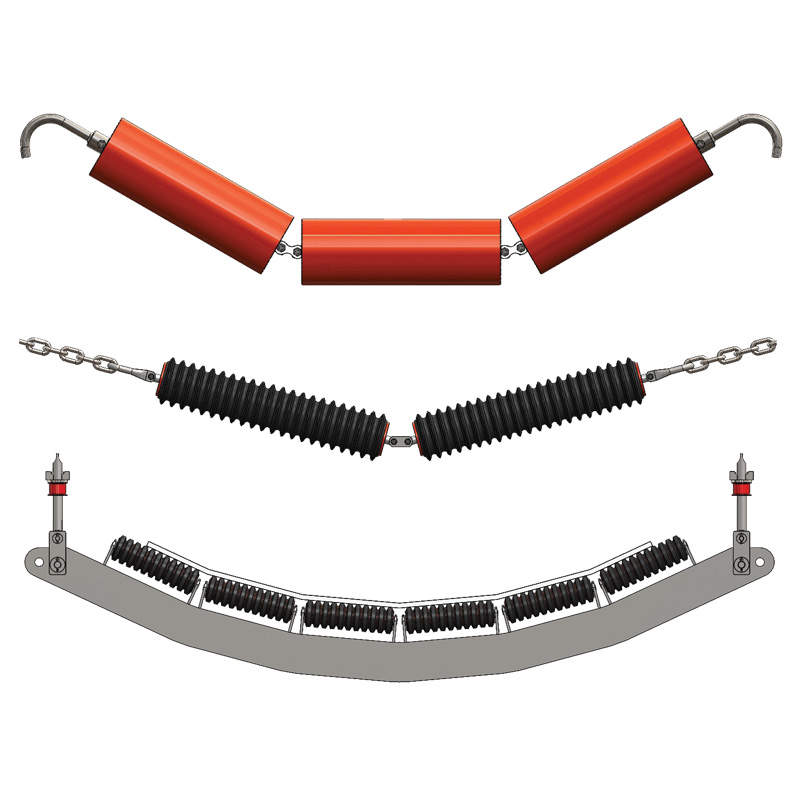

| Frame Type | Fixed/Suspended | Fixed/Suspended | Fixed |

| Operating Temperature (℃) | -40~+60 | -40~+60 | -40~+60 |

Technical Features of Broken Belt Catcher

Full-Section Synchronous Locking

Breaking through the limitation of traditional single-side capture, it adopts a symmetrical wedge-shaped brake block structure. At the moment of belt breakage, the brake blocks on both sides synchronously tighten towards the center of the belt, locking both the carrying section and the return section simultaneously to achieve 100% full-section coverage. This completely eliminates secondary risks such as belt slipping, stacking and material falling. The frame is made of Q355B high-strength section steel and alloy steel composite, inspected by ultrasonic flaw detection, and can withstand instantaneous impact of 1.5 times the design load. Combined with buffer braking technology, it precisely controls deceleration to avoid equipment damage.

Full-Scenario Modular Adaptation

Adopting modular precise parameter configuration, it fully covers from light load to heavy load and from small belt width to large belt width. There is no need to distinguish the conveying direction, and it is universally applicable for upward, downward and horizontal conveying. It features standardized interface design with ZOOMRY's own host equipment such as belt conveyors, bucket wheel stacker-reclaimers and Mobile Ship Loaders, enabling quick matching without additional modification. For conveying equipment of other brands, customized adaptation services can be provided by adjusting frame size and installation interfaces to achieve seamless cross-brand and cross-equipment compatibility.

Full-Standard Compliance Guarantee

Following the design principle of "global standard integration", it fully complies with core standards such as China's NB/T 11464-2023, EU EN 12895, North American ASTM D3794 and international ISO 5048. It has obtained CE Certification, ATEX Explosion-Proof Certification, MA Coal Mine Safety Mark Certification and REACH Compliance Certification. Whether for the domestic market or overseas markets such as Europe, North America and Southeast Asia, it can directly meet access requirements without additional adaptation and modification.

Core Advantages of Broken Belt Catcher

Full Protection Coverage

The full-section synchronous locking design achieves 100% protection coverage, far exceeding traditional single-side capture equipment. The rated braking force reserves sufficient safety redundancy, enabling stable capture even under extreme loads. The braking deceleration is precisely controllable, balancing protection effect and equipment protection, and fundamentally eliminating various safety accidents caused by belt breakage.

Wide Adaptation Range

The Broken Belt Catcher covers 50-1500kN braking force, 650-2200mm belt width, 800-4000N/mm belt strength, and adapts to full inclination angles of -25~+32°, meeting the needs of different scenarios such as light-load small conveyor lines and heavy-load large belt conveyors. It reduces the complexity of customer selection and the cost of spare parts storage, and one product family can cover full-scenario protection needs.

Stable Operation in Extreme Environments

The operating temperature ranges from -40~+60℃, adapting to complex environments such as extreme cold in frigid zones, high temperature in tropical zones, salt spray in coastal areas, and high dust in mines. With a protection level of IP65-IP67 and corrosion resistance level complying with C4-C5-M standard, key components undergo special anti-corrosion treatment, capable of resisting erosion from humidity, dust and corrosive gases, and the failure rate is much lower than the industry average.

Convenient Operation and Maintenance

Core components adopt a modular design. Wear parts are common with ZOOMRY's existing components such as idlers and cleaning scrapers, facilitating procurement and replacement. The design life is no less than 10 years. Daily maintenance only requires regular visual inspection and brake block wear detection, no complex professional tools are needed, and the long-term operating cost is significantly lower than that of similar imported products.

Adaptable Equipment and Scenarios

Mining Industry

Suitable for underground inclined shaft belt conveyors and open-pit mine supporting belt conveyors, coping with harsh working conditions such as high inclination angles, high dust, humidity and no electricity. The heavy-load Broken Belt Catcher has passed explosion-proof certification with a protection level of IP67. Mechanical + hydraulic auxiliary triggering ensures instant locking at the moment of belt breakage, avoiding ore falling and equipment damage; the general-purpose product adopts pure mechanical + gravity drive, adapting to extreme climates in open-pit mines, and collaborates with bucket wheel stacker-reclaimers to ensure continuous production.

Port Industry

The anti-corrosion design is optimized for the port's high salt spray and high humidity environment, adapting to mobile ship loader supporting belt conveyors and bulk material belt conveyors. The heavy-load product adopts a compact frame, adapting to large belt width and high belt speed working conditions, and full-section locking avoids high-speed belt slipping; the general-purpose product supports quick-installation without modifying existing equipment, and links with the port automatic control system to reduce operation interruption time and improve transfer efficiency.

Power Plant Industry

Suitable for power plant coal conveying belt conveyors and transfer belt conveyors, meeting the demand for 24-hour continuous operation. The general-purpose product adopts pure mechanical + gravity drive, not relying on external power supply, avoiding protection failure during power outages, and the sealed structure prevents coal dust intrusion; the light-load product features flexible installation and simple maintenance, providing full-process protection for the coal conveying system and avoiding power generation interruption caused by belt breakage.

Building Materials Industry

Adapts to cement plant aggregate belt conveyors and mixing station fly ash conveying belt conveyors, coping with high-wear and high-dust working conditions. The general-purpose product adopts a wear-resistant rubber composite braking surface to extend service life, and the anti-corrosion coating resists cement dust erosion; the light-load product's full-section capture prevents material leakage, ensuring production compliance with environmental protection requirements and avoiding production line stagnation caused by belt breakage.

Broken Belt Catcher Selection Guide

-

Select by core parameters of equipment: According to the belt width, inclination angle, belt strength and load condition of the conveying equipment, choose the 50-200kN series for light-load working conditions, 300-600kN series for medium-load working conditions, and 800-1500kN series for heavy-load working conditions to ensure precise matching.

-

Select by environmental grade: Choose IP65 protection and C4 corrosion resistance models for conventional environments; IP67 protection and C5-M corrosion resistance models for harsh environments; prioritize pure mechanical drive (for frigid zones) or matching heat dissipation structures (for tropical zones) for extreme temperature scenarios.

-

Select by compliance requirements: Products for the domestic market must comply with NB/T 11464-2023 standard, and MA certification is required for coal mine scenarios; products for the European market need CE, ATEX certification and REACH compliance; products for the North American market must comply with ASTM D3794 standard, and select models with corresponding certifications as needed.

ZOOMRY Service System

Full-Process Quality Control System

Establish a production control process in line with ISO 9001 standards. Core components are made of high-quality materials, undergoing multiple inspections such as ultrasonic flaw detection, dynamic load testing, high-low temperature environment testing and simulated belt breakage testing. Each product is provided with a complete test report before leaving the factory, and key performance indicators are recorded throughout the process to ensure quality meets standards.

Full-Experience Technical Endorsement

ZOOMRY has been deeply engaged in the field of bulk material conveying equipment for many years. The engineer team has rich practical experience in global projects and is familiar with industry standards and working condition characteristics in different regions. Product technology iteration is based on feedback from real working conditions, targeting optimization of core structures and materials to ensure technical practicality and advancement.

Full-Cycle Service Guarantee

In the early stage, provide one-on-one selection consultation and mechanical calculation reports, and customized design for special working conditions; in the middle stage, provide detailed installation guidance, 3D drawings, etc., and on-site commissioning for large-scale projects; in the later stage, establish equipment files, regularly remind maintenance nodes, provide 7×24-hour technical consultation, and offer graded warranty (2 years for light-load models, 3 years for general-purpose models, 5 years for heavy-load models). Free repair or replacement is provided for non-human-caused failures during the warranty period.

ZOOMRY

ZOOMRY