The ZOOMRY spiral scraper conveyor for Loading is an integrated equipment designed specifically for the full process of “scraping-loading” bulk materials, with a core focus on “efficient and seamless operations,” combining the wear-resistant characteristics of scraper equipment with the convenience of loading functions. Equipped with an 800-1600 mm wide Conveyor Belt and a fixed 4-meter discharge height, it achieves a broad capacity range of 100-2000 tph. Paired with optional rubber or steel tracked chassis and a 100-meter wireless remote control system, it completes the seamless process of “material pile retrieval-belt conveying-truck loading” without requiring additional transfer equipment. Certified by international standards such as CE and EAC, and backed by comprehensive quality control, the equipment is adaptable to various bulk material operations in stockyards, ports, and other scenarios, making it the preferred solution for “reducing process stages, enhancing efficiency, and strong adaptability” in the transfer of bulk materials like gravel, coal, and ore. It also serves as a complementary configuration for similar self-propelled bulk material handling equipment.

Advantages of the spiral scraper conveyor for Loading

The core value of the ZOOMRY Spiral scraper conveyor for loading lies in breaking the inefficient model of traditional bulk material handling, which relies on “multiple equipment coordination and multi-stage transfers.” Through functional integration and structural optimization, it addresses pain points such as site constraints, excessive manual intervention, and long operational cycles, while meeting global clients’ dual demands for equipment compliance and durability.

The conveyor adopts a deeply integrated design of “spiral scraper unit and conveyor belt loading unit.” The spiral system, with a 500-800 mm outer diameter and 2-3.2 m scraping width, efficiently retrieves bulk materials. Its 6-8 mm thick blades are inlaid with high-strength alloy teeth (hardness HRC60), capable of breaking up slightly caked materials and reducing wear, ensuring continuous and clog-free scraping. The retrieved materials are directly transported to the loading end via a 12-15 m long inclined conveyor belt, with a 4-meter discharge height precisely matching the cargo box height of mainstream global freight trucks (3.5-4.2 m), eliminating the need for secondary lifting or transfer, fundamentally reducing material spillage losses. Compared to the traditional stepwise approach of “scraper + transfer conveyor + loader,” this integrated design improves operational efficiency by over 40%, significantly shortening the loading cycle for each batch of bulk materials, while reducing equipment investment and manual operation costs.

The tracked chassis provides all-terrain adaptability. As the core of the self-propelled design, the chassis offers two configurations to handle different operating environments: the rubber tracks, model 4009068 with an effective length of 2.9 m, have a ground pressure of only 0.07 MPa, suitable for soft terrains like wet stockyards or port stacking areas, preventing equipment entrapment and avoiding damage to ground infrastructure, with a minimum turning radius of 5 m for flexible positioning in confined spaces; the steel tracks, model 40013554 with an effective length of 3.6 m, have carburized and quenched track plates (hardness HRC58-62), improving wear resistance by 80%, ideal for rough, hard surfaces like gravel stockyards in mines or port terminals, resisting scratches from sharp materials and extending chassis lifespan. Both chassis types are driven by hydraulic motors paired with planetary reducers, delivering an output torque of up to 3500 N·m, enabling smooth start-stop and steering even under full load. The chassis outer width is 2.3 m, with customizable widening options to further enhance stability on complex terrains, adapting to diverse global climates and site conditions.

The dual-mode control system balances outdoor durability and operational convenience. The equipment is equipped with a 304 stainless steel rainproof control cabinet with an IP65 protection rating, effectively resisting water and dust intrusion in outdoor environments like ports and stockyards, with internal components sourced from internationally renowned brands for long-term stable operation. The wireless remote control handle, with a 100-meter effective range, supports full functionality, including spiral speed adjustment, chassis movement, conveyor belt start-stop, and emergency shutdown, allowing operators to monitor loading progress from the truck cab or a safe area, avoiding close contact with dust and moving equipment, thus enhancing operational safety. Additionally, the control system supports multi-language switching (English, Russian, Spanish, Chinese), with an interface focused on “scraping-loading synergy” needs, capable of one-touch retrieval of three sets of commonly used operational parameters (e.g., spiral speed and conveyor belt speed for different materials), eliminating the need for repeated adjustments when switching material types, significantly reducing the learning curve for operators across different regions and minimizing operational errors due to parameter misconfigurations.

Key Components of the Spiral scraper conveyor for loading

The long-term stability of the ZOOMRY Spiral Scraper Conveyor for Loading stems from the targeted development of core components for “wear resistance, synergy, and ease of maintenance.” Each component undergoes multi-condition simulation testing and international standard verification to ensure compatibility with various bulk material types and operational intensities worldwide.

The spiral scraper system is the “power starting point” of integrated operations. With 6-8 mm thick blades inlaid with high-strength alloy teeth, it offers 120% higher wear resistance than ordinary carbon steel blades, capable of withstanding long-term impacts from hard materials like gravel and ore. The spiral outer diameter ranges from 500-800 mm, paired with a 2.4-3.6 m material pickup width, allowing flexible adjustment of scraping volume based on material pile density—large-diameter spirals for lightweight materials to achieve high capacity, and medium-to-small spirals for medium-heavy materials to ensure precise speed control and avoid overloading. The drive unit uses 22-75 kW high-power motors, matched to capacity gradients: 22-37 kW for 100-500 tph, 45-55 kW for 500-1200 tph, and 75 kW for 1200-2000 tph, with motor efficiency exceeding 95.5% and an IP55 protection rating to withstand dust and moisture in outdoor environments. The accompanying reducer offers three models: ZQ350 dual output, ZQ400 dual output, and ZLY250 hard-tooth surface dual output, all with transmission efficiencies above 97%, with the hard-tooth surface reducer providing 50% higher load-bearing capacity than standard models, capable of withstanding instantaneous impact loads during spiral scraping, preventing operational interruptions due to drive failures.

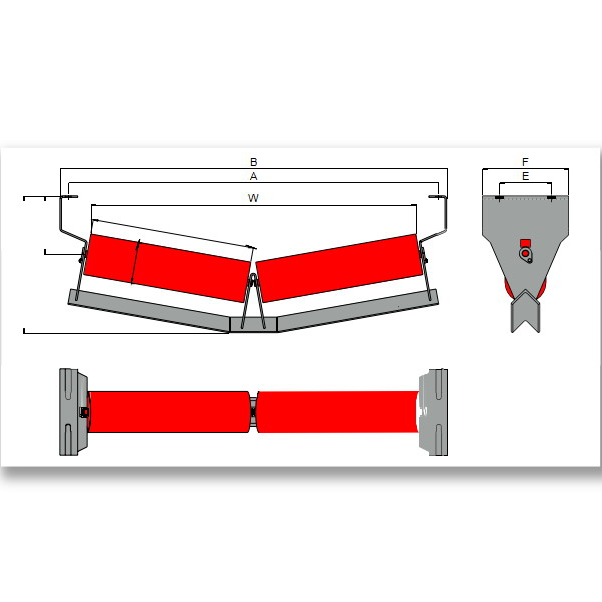

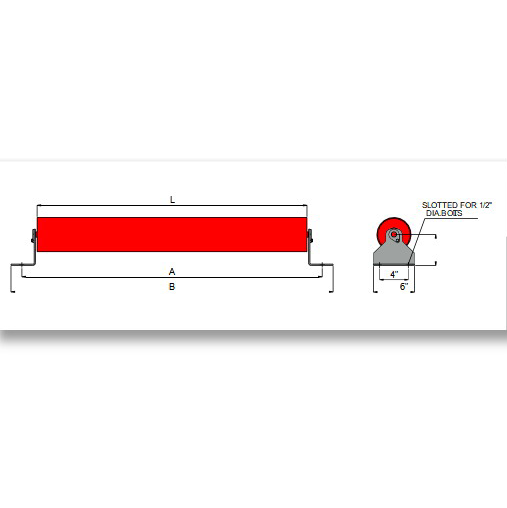

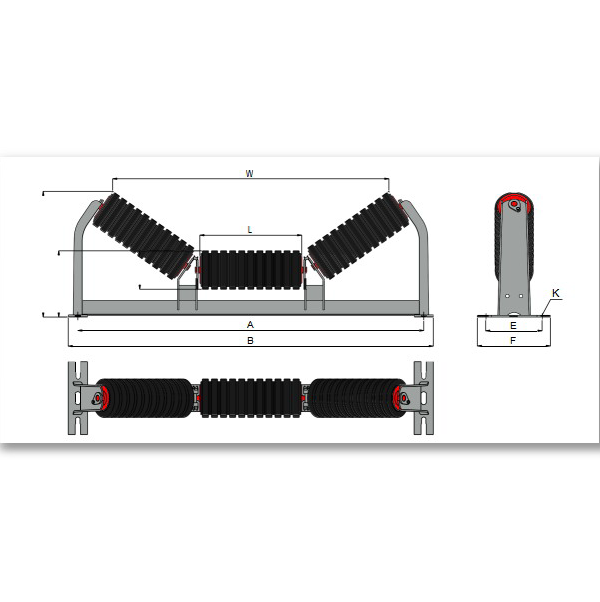

The conveyor belt loading system is the critical link between “scraping and loading.” The belt width ranges from 800-1600 mm, flexibly selected based on capacity and material block size: 800-1000 mm for 100-800 tph, and 1200-1600 mm for 800-2000 tph. The conveyor belt is made of nylon-core anti-slip rubber with a longitudinal tensile strength of 1600 N/mm, featuring an 8 mm deep diamond-patterned surface that enhances anti-slip performance by 40%, preventing slippage of wet coal or sticky gravel during transport. Both sides are equipped with 350 mm high wear-resistant rubber skirts with embedded steel wire frameworks to reduce material side leakage, meeting the needs of “continuous loading without loss.” The drive uses a 15-30 kW electric drum, eliminating the need for additional motor and reducer installations, offering a compact structure and easy maintenance. The electric drum has an IP54 protection rating with built-in overheat protection, automatically stopping at temperatures above 120℃ to prevent burnout risks. The conveyor belt length of 12-15 m, paired with a 4-meter fixed discharge height, perfectly matches mainstream global freight trucks, enabling direct loading without secondary transfers, a key advantage distinguishing it from ordinary scraper conveyors.

The hydraulic and chassis system provides power support for flexible operations. The core is an 11-18.5 kW hydraulic pump station, matched to chassis type and spiral specifications: 11 kW for rubber tracked chassis, and 15-18.5 kW for steel tracked chassis and large spiral specifications. The pump station has a 200 L oil tank with dual filtration devices (filtration accuracy of 10 μm), achieving a hydraulic oil cleanliness level of NAS 8, reducing wear on hydraulic components with an annual system failure rate below 0.5%. The hydraulic pipelines use high-pressure hoses (30 MPa working pressure) with stainless steel connectors, offering excellent corrosion resistance suitable for complex environments like high-salt-spray ports or dusty mines. The chassis travel system, linked with the hydraulic motor, supports stepless speed regulation (travel speed 0-3 km/h), adjustable to loading rhythms. It also features hydraulic shock absorbers to mitigate jolts on uneven terrain, preventing material spillage and vibration damage to core components, ensuring “stable scraping and loading during movement” to meet the needs of flexible operations across multiple piles and berths.

Global-Compatible Transport and Installation Solutions

Addressing the pain points of global clients, such as “complex cross-border transport and long on-site installation cycles,” the ZOOMRY Spiral Scraper Conveyor for Loading adopts a “modular disassembly + high pre-assembly ratio” design, ensuring integrated performance while significantly reducing transport and installation barriers, enabling rapid project commissioning in different regions.

The modular disassembly design ensures globally compliant transport. The equipment can be disassembled into four standard units: spiral scraper module, conveyor belt module, tracked chassis module, and control module, each sized to fit a 40-foot high-cube container (12.03 m long × 2.35 m wide × 2.69 m high). The spiral module folds hydraulically to a height below 2.5 m and weighs under 18 tons; the conveyor belt module splits into 2-3 segments, each no longer than 6 m and weighing no more than 10 tons; the chassis and control modules are integrated into waterproof enclosures, requiring no permits for oversized or overweight transport. Compared to the traditional “special transport + oversized customs clearance” model for integrated equipment, this design reduces cross-border logistics costs by 40%. Core components are factory-packaged with anti-rust and waterproof materials to prevent damage from jolts or moisture during transport, accommodating logistics conditions in regions like Europe, Southeast Asia, and Africa.

The high pre-assembly ratio shortens on-site commissioning time. The equipment is 85% pre-assembled at the factory, including precise spiral-to-motor connections, conveyor belt installation and tuning, initial hydraulic pipeline connections, and control system parameter calibration, undergoing 80 hours of full-load testing (simulating scraping-loading synergy across different capacities) to ensure fault-free on-site installation. On-site installation requires only three core steps: first, modular unit assembly, connecting the spiral module to the chassis and the conveyor belt module to the frame with high-strength bolts, completed by two people in 2 hours; second, final connection of hydraulic pipelines and electrical plugs using quick leak-free connectors, taking no more than 1 hour; third, no-load testing and parameter fine-tuning, checking scraping-loading synergy and remote control functions, completed by a skilled team in one day for full commissioning. ZOOMRY provides a multi-language technical manual with step-by-step operation guides, highlighting special considerations for heavy equipment installation, such as bolt tightening torque and hydraulic system venting procedures, along with 24-hour online technical support via video guidance to assist clients in resolving installation issues, enabling deployment without a professional installation team and accommodating technical capability differences across regions.

Quality Compliance and Global Operational Assurance

As equipment designed for global markets, the ZOOMRY Spiral Scraper Conveyor for Loading ensures compliant use in various countries and regions through multiple international certifications and comprehensive quality control, guaranteeing long-term operational reliability.

International certifications cover mainstream market entry standards. The equipment has passed EU CE certification, covering the Machinery Directive (2006/42/EC) and Electromagnetic Compatibility Directive (2014/30/EU), completing 12 specialized tests for bulk material handling equipment safety requirements, including structural load-bearing strength, emergency braking response, electrical safety protection, and electromagnetic compatibility, enabling direct entry into the European Economic Area (EEA) market. It also holds EAC certification from the Russian Customs Union, meeting the operational requirements of “low-temperature, high-dust” environments in CIS countries, with technical documentation provided in Russian, including scraping-loading operation guidelines and low-temperature maintenance points for local regulatory reviews. Additionally, the equipment complies with ISO 9001 quality management and ISO 14001 environmental management systems, with a fully traceable production process from raw material intake to finished product delivery, with detailed quality records for each step to ensure consistency and compliance in mass production.

Comprehensive quality testing ensures multi-scenario reliability. ZOOMRY’s in-house quality testing center is equipped with a chemical laboratory, hardness laboratory, spiral performance testing laboratory, and hydraulic system high-pressure testing laboratory, featuring over 60 professional testing devices. Core components undergo rigorous testing: spiral blades and alloy teeth are subjected to 1000 hard gravel impact tests (50 kg per block) and 500-hour wear tests to ensure no significant wear or deformation; the conveyor belt undergoes 100-hour full-load tensile testing and -30℃ to 60℃ weathering tests to ensure no breakage or aging, adaptable to global climates; the hydraulic system undergoes 72-hour sealing tests (30 MPa working pressure) to ensure no leaks; the control system undergoes 100-hour rain tests (verifying IP65 protection) and 100-meter wireless signal anti-interference tests to ensure normal functionality. Each unit undergoes 15 rigorous tests before delivery, including “scraping-loading synergy tests (100-2000 tph capacity switching),” “tracked chassis climbing tests (slope ≤15°),” and “low-temperature startup tests (-30℃),” with delivery only upon meeting standards, ensuring reliable operation across global multi-scenario applications.

Technical Parameters

| Item | Specification Parameters |

|---|---|

| Equipment Type | Tracked spiral scraper conveyor for Loading (Integrated Operations) |

| Capacity Range (tph) | 100-2000 |

| Applicable Material Types | Gravel, coal, grain, ore, aggregates, etc. |

| Spiral Outer Diameter (mm) | 500-800 |

| Spiral Scraping Width (m) | 2-3.2 |

| Material Pickup Width (m) | 2.4-3.6 |

| Blade Configuration | 6-8 mm blades + inlaid alloy teeth |

| Motor Power (kW) | 22-75 |

| Reducer Model | ZQ350 dual output / ZQ400 dual output / ZLY250 hard-tooth surface dual output |

| Conveyor Belt Width (mm) | 800-1600 |

| Conveyor Belt Length (m) | 12-15 |

| Conveyor Belt Power (kW) | 15-30 (electric drum) |

| Conveyor Belt Material | Nylon-core anti-slip rubber belt |

| Discharge Height (m) | 4 |

| Hydraulic Pump Station Motor Power (kW) | 11-18.5 |

| Tracked Chassis | Rubber tracks (4009068, effective length 2.9 m); Steel tracks (40013554, effective length 3.6 m), chassis outer width 2.3 m (supports widening) |

| Control System | Stainless steel rainproof control cabinet (IP65), 100 m wireless remote + local control |

| Motor Protection Rating | IP55 (spiral/pump station motor), IP54 (electric drum) |

| Applicable Ambient Temperature (℃) | -30\~60 (resistant to extreme climates) |

| Optional Configurations | Spiral blade wear-resistant coating, conveyor belt Rain Cover, material level sensor, chassis widening kit |

Why Choose ZOOMRY

Client Value

Choosing the ZOOMRY Spiral Scraper Conveyor for Loading provides global clients with significant value in efficiency, cost, and adaptability. In terms of efficiency, the integrated “scraping-loading” design eliminates 1-2 transfer stages, significantly improving operational efficiency compared to traditional equipment combinations, while the 100-meter wireless remote control reduces manual intervention, with a single unit replacing multiple operators, lowering labor costs. The 4-meter discharge height precisely matches trucks, avoiding secondary lifting losses, shortening single-batch loading times, and enhancing overall operational continuity.

In terms of cost, the 100-2000 tph capacity range covers small, medium, and large-scale operations, eliminating the need for separate equipment for different capacities, reducing initial investment. High-wear-resistant components (e.g., alloy teeth, nylon-core conveyor belt) extend replacement cycles, reducing maintenance costs by 35% compared to ordinary scraper conveyors. The equipment’s low failure rate (annual failure rate <0.8%) minimizes downtime losses, ensuring long-term stable operations and further controlling comprehensive operational costs.

In terms of adaptability, the dual rubber/steel tracked chassis adapts to soft and hard terrains, requiring no additional site modifications. The multi-language control system and CE/EAC certifications accommodate operational habits and regulatory requirements across global regions. The modular transport design reduces cross-border logistics costs, meeting project deployment needs in regions like Europe, Southeast Asia, and Africa, enhancing the equipment’s global applicability.

Service Support

ZOOMRY has established a comprehensive service system of “technical support + spare parts assurance + specialized training” tailored to global client needs, ensuring long-term stable equipment operation. For technical support, multi-language technical documentation is provided, including operation manuals, maintenance guides, and troubleshooting manuals, covering scraping-loading parameter settings for different materials, tracked chassis maintenance, and control system fault handling, accompanied by clear diagrams. 24-hour online technical support (email: oversea@zoomry.cn; phone: +86-13164016717) offers rapid engineer responses, with video guidance to resolve equipment debugging and troubleshooting issues. Assigned engineers have over 5 years of bulk material equipment service experience, familiar with equipment pain points in global multi-scenario applications.

For spare parts assurance, ZOOMRY leverages an efficient global supply chain collaboration system, pre-stocking common spare parts such as spiral blades, alloy teeth, conveyor belts, and hydraulic filters. Upon client request, parts are shipped quickly via international logistics, with delivery cycles optimized based on the client’s region. For key clients, a “spare parts pre-planning service” is offered, developing procurement and storage plans based on equipment operation frequency and wear part replacement cycles, using bulk shipments or phased restocking to avoid downtime due to part shortages.

For specialized training, ZOOMRY offers online and offline training services for client teams in different regions, covering scraping-loading synergy parameter optimization, tracked chassis maintenance, and emergency fault handling (e.g., spiral material jams, remote signal interruptions). Through a combination of theoretical and practical training, clients’ teams master key equipment operation points, accommodating technical capability differences across regions and supporting efficient client operations.

ZOOMRY

ZOOMRY