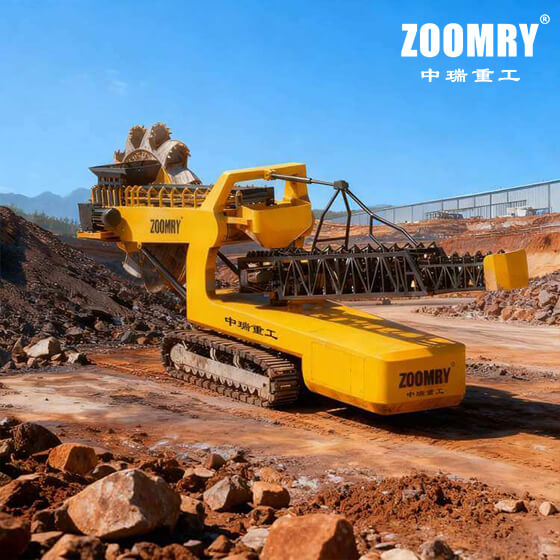

The Bucket Wheel Reclaimer from ZOOMRY, as a professional bulk material reclaiming equipment and Mobile Bucket Wheel unit, has a rated handling capacity covering 500-3000 m³/h, equipped with 8-12 customized bucket wheels (diameter 5254-8200 mm), bucket wheel drive power of 75-1100 kW, combined with a ±65-360° full-angle slewing mechanism and 125-193 kPa low ground pressure track system. It can efficiently meet the demand for precise bulk material reclaiming in multiple scenarios. Through CE and EAC international certifications, it becomes the preferred choice in the field of mine reclaimers and industrial bulk material processing for "precise reclaiming, flexible mobility, stable operation"; it can also serve as a specialized reclaiming supplement for bucket wheel stacker reclaimers, meeting the core demands of global industries for efficient and precise bulk material reclaiming.

Core Highlights of Bucket Wheel Reclaimer

The Bucket Wheel Reclaimer from ZOOMRY takes "reclaiming precision control, operation range coverage, complex site adaptation" as its technical core, specifically solving the pain points of traditional reclaiming equipment such as "large reclaiming deviation, limited operation radius, weak site adaptability." Through coordinated optimization of the bucket wheel, slewing, and track systems, it meets high-precision reclaiming needs while ensuring stable operation in complex environments, aligning with global customers' dual requirements for compliance and durability.

Customized Optimization of Bucket Wheel System

The bucket wheel system, as the execution core for precise reclaiming, adopts an "equidistant circumferential layout + arc surface conforming design," with 8-12 bucket wheels flexibly configured according to reclaiming scale: 8-10 bucket wheels for small to medium capacity scenarios (500-1500 m³/h), 10-12 for large-scale operations (1500-3000 m³/h), single bucket capacity 0.25-0.71 m³, combined with adjustable 2-6 r/min speed, achieving "demand-based reclaiming" precise matching. The bucket wheel blades use 16 mm thick Mn13 wear-resistant manganese steel, with 3 mm tungsten carbide alloy layer welded on the surface, improving wear resistance by 180% over ordinary carbon steel, capable of long-term resistance to impacts from hard materials; the arc surface design allows the blades to closely conform to the stockpile during capture, controlling reclaiming deviation within 2%, far superior to industry average levels.

The inner side of the blades is fitted with PTFE-coated anti-stick guide plates, with material residue rate ≤0.2%, reducing reclaiming volume deviations and manual cleaning frequency; the drive system features load-adaptive torque control, real-time monitoring capture resistance via sensors, automatically reducing speed (minimum 2 r/min) and alarming when encountering large blocks, avoiding bucket wheel jamming or motor damage, ensuring continuous precise reclaiming.

Full-Angle Design of Slewing Mechanism

The slewing mechanism determines the breadth of the reclaiming range; the bucket wheel reclaiming arm supports ±65-360° full-angle slewing, with the discharge arm adjustable ±90-±105° relative to the reclaiming arm, paired with 15 m upward digging height and 1 m downward digging height; a single unit can cover an 80 m diameter stockpile area, achieving "stockpile edge-center" and "bottom-top" dead-angle-free reclaiming without frequent repositioning. The slewing drive adopts a "dual-motor synchronous + planetary reducer" combination, with output torque of 10000 N·m, slewing precision ≤0.3°, controlling reclaiming position deviation within 100 mm, meeting precision demands for layered reclaiming and fixed-point reclaiming.

The slewing bearing selects four-point contact ball bearing (diameter 3-5 m), with load capacity of 1800 kN, capable of withstanding axial and radial loads and overturning moments simultaneously, with bearing clearance ≤0.1 mm, maintaining high precision in long-term operation; the surface achieves "nitriding + sealing" double protection, improving anti-dust and anti-corrosion performance by 60%, adapting to high-dust, high-humidity operation environments, with service life exceeding 60000 hours.

Low Ground Pressure of Track Travel System

The track travel system is specially designed for complex sites, with drive form optionally "hydraulic motor + reducer" or "motor reducer," operation modes divided into operation mode (0.51 km/h) and transition mode (0-2 km/h); low-speed travel in operation mode ensures precise reclaiming, high-speed repositioning in transition mode improves efficiency. The 600 mm wide track plates control ground pressure at 125-193 kPa, only 1/2 that of traditional wheeled equipment, evenly distributing weight on soft ground to avoid entrapment, while reducing crushing damage to ground facilities.

The track tensioning system uses hydraulic automatic adjustment, with pressure sensors real-time monitoring ground hardness; loosening tension (8-10 kN) on soft ground to increase contact area, tightening (12-15 kN) on hard ground to reduce deviation; adapting to different sites without manual intervention. The track drive wheel and guide wheel use integrally forged steel, with tooth surface quenching hardness HRC60, wear resistance extended to over 12000 hours, lowering component replacement costs.

Core Component Integration of Bucket Wheel Reclaimer

The long-term reliability of the Bucket Wheel Reclaimer from ZOOMRY stems from the deep integration of core components around "precision, high-load resistance, easy maintenance"; each part undergoes multi-condition simulation testing to ensure adaptation to continuous precise reclaiming demands in global industrial scenarios.

Drive Transmission Unit

The bucket wheel drive system centers on "precise speed control + impact resistance," with drive motor power matched by reclaiming scale gradients (75-1100 kW), using high-efficiency permanent magnet synchronous technology, significantly energy-saving compared to ordinary asynchronous motors, with IP55 protection level paired with anti-condensation heating device, capable of resisting high dust and high humidity erosion. The matching hard-tooth surface planetary reducer achieves 97.5% transmission efficiency, 50% higher load capacity than ordinary reducers, capable of withstanding instantaneous impact loads from hard material capture (maximum impact torque 1.8 times rated).

The reducer and bucket wheel shaft use "elastic coupling + positioning pin" dual connection, buffering startup impacts while ensuring bucket wheel coaxiality deviation ≤0.05 mm to avoid eccentric reclaiming deviations; the drive system is equipped with torque monitoring and protection device, real-time feedback load status, automatically reducing speed when load exceeds 120% rated, cutting power when exceeding 150%, effectively protecting core parts and adapting to load fluctuations of different materials.

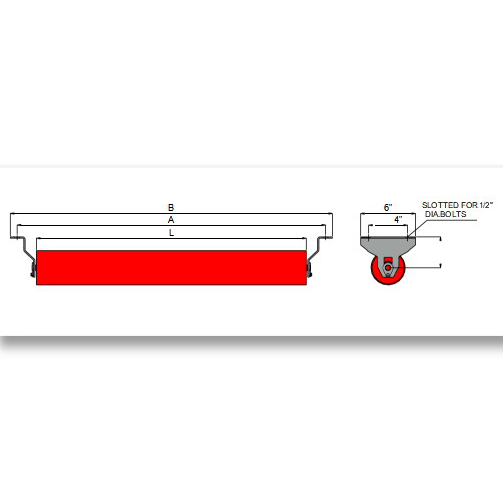

Conveyor Connection System

The conveyor system, as the "reclaiming-transport" core connection, focuses on "stable + low residue": Conveyor Belt width 1200-1600 mm, belt speed 2.5-5.0 m/s, precisely matched to reclaiming volume—1200-1500 m³/h with 1200 mm belt width + 2.5-3.0 m/s belt speed, 1500-3000 m³/h with 1400-1600 mm belt width + 3.0-5.0 m/s belt speed, ensuring synchronized reclaiming and conveyance rhythm.

The conveyor belt selects high-wear-resistant PVG flame-retardant rubber belt (14 mm thickness), with longitudinal tensile strength of 2000 N/mm; surface "diamond anti-slip pattern + polishing" treatment improves anti-slip performance by 50%, avoiding slippage of damp materials; both sides equipped with 400 mm high wear-resistant rubber skirts + soft sealing strips, side leakage rate ≤0.5%. The system is equipped with passive hydraulic aligning idlers (alignment response ≤2 seconds) and "heavy-duty polyurethane scraper + brush" combination (cleaning rate 99.8%), thoroughly clearing residual materials, reducing belt wear, extending service life to over 3 years.

Electrical Control and Hydraulic Integration

The electrical control system centers on "precision planning of reclaiming paths," with 15-inch high-definition HMI touch screen supporting multi-language switching, storing 5 groups of reclaiming scenario programs, with one-click invocation during switching without repeated debugging. The system supports three control modes, all adapted to precise reclaiming:

- PLC full automatic mode: Through laser level meter + infrared positioning sensor collecting data, automatically plans layered reclaiming, fan-shaped reclaiming, and other paths, synchronously controlling bucket wheel speed, track travel, and slewing angle to achieve unattended precise reclaiming with deviation ≤3%;

- Remote control mode: 200 m industrial-grade wireless remote controller (IP67 anti-interference compliant), allowing operators in safe areas to real-time adjust reclaiming parameters, ensuring uniform reclaiming layer thickness;

- Manual mode: Quick switch in emergencies, equipped with reclaiming volume warning function, automatically reducing speed and alarming when load exceeds rated threshold, ensuring precise and controllable operation.

The hydraulic system provides power for track travel and slewing mechanisms; the graded hydraulic pump station is adapted to overall machine power of 166-1410 kW per specifications, oil tank capacity 1200-2500 L, quadruple filtration device (5 μm accuracy) ensures hydraulic oil cleanliness at NAS 7 level, reducing hydraulic element wear, with system annual failure rate below 0.3%. Hydraulic pipelines use stainless steel fittings + high-pressure hoses (working pressure 31.5 MPa), with excellent anti-corrosion performance adapting to multi-dust and high salt spray environments; modular quick-connect design shortens local fault replacement time to within 1.5 hours.

Compliance and Quality Control

As a precise reclaiming equipment for global markets, the Bucket Wheel Reclaimer from ZOOMRY ensures regulatory compliance in different countries and regions through multiple international certifications and specialized quality testing, while guaranteeing reliability in continuous operation.

International Compliance Certification

The equipment passes EU CE certification (Machinery Directive 2006/42/EC, Electromagnetic Compatibility Directive 2014/30/EU), completing 14 specialized safety tests for precise reclaiming equipment, including reclaiming mechanism load strength (simulating 3 times rated load), slewing emergency braking response (≤0.5 seconds), electrical safety protection (IP65), resistance to strong electromagnetic interference, etc., allowing direct entry into the European Economic Area market; it passes Russian Customs Union EAC certification, meeting low-temperature operation demands, with technical documents provided in Russian versions, including low-temperature lubrication and anti-freeze startup, facilitating local regulatory review.

The equipment overall complies with ISO 9001 quality management system and ISO 14001 environmental management system; the production process is fully traceable, from raw material entry detection to finished product exit; each process has detailed quality records, ensuring consistency and precision in batch production.

Specialized Quality Testing

ZOOMRY's self-built reclaiming equipment specialized testing laboratory is equipped with over 60 professional devices, conducting targeted tests on core components:

- Bucket wheel system: After thousand-times layered reclaiming simulation test (reclaiming layer thickness deviation ≤50 mm) and 500-times large block material impact test, blades without deformation or cracks;

- Slewing and conveyor system: 360° slewing precision test (deviation at any angle ≤0.3°), 100 hours continuous slewing test (support temperature ≤65℃), 100 hours full-load conveyance test (deviation ≤10 mm, residue rate ≤0.2%);

- Electrical control and hydraulic system: 100 hours electromagnetic interference test, 200 m wireless remote signal stability test, 100 hours high-pressure sealing test (no leaks), -30℃ low-temperature startup test (normal function).

Each unit must pass full-range reclaiming deviation test, -30℃ low-temperature startup test, track climbing test (slope ≤12°), slewing emergency braking test, and other 18 strict tests before leaving the factory, and is delivered only after qualification, ensuring reliable operation in global scenarios.

Modular Transportation and Rapid Installation

For global industrial projects' "difficult cross-border transportation, long installation cycles" pain points, the equipment adopts "reclaiming-specific modular disassembly + high-ratio pre-assembly" design; while ensuring precise reclaiming performance, it substantially reduces deployment difficulty, ensuring rapid commissioning.

Globally Adapted Modular Transportation Solution

Based on "reclaiming function priority" principle, the equipment is disassembled into 5 standard units: "bucket wheel reclaiming module, slewing drive module, track chassis module, electrical control module, hydraulic module," all adapted to 40-foot high containers without special transport permits. The bucket wheel reclaiming module reduces height to 2.4 m via hydraulic folding, weight ≤32 tons; the track chassis module is divided into left and right parts (single weight ≤45 tons); electrical control and hydraulic modules are integrated into waterproof boxes (1.5 m × 1.2 m × 2.0 m), adapting to global multi-region logistics conditions.

Core reclaiming parts (bucket wheel, slewing bearing, etc.) undergo "anti-rust + anti-collision" double-layer packaging before leaving the factory to avoid precision damage from transport bumps; compared to traditional integral equipment, cross-border logistics costs are reduced by 40%.

Efficient Pre-Assembly Process for Rapid Deployment

Before leaving the factory, the equipment completes 85% pre-assembly, focusing on reclaiming core functions: precise docking of bucket wheel and reclaiming arm (coaxiality deviation ≤0.05 mm), no-load debugging of slewing drive system (precision ≤0.3°), hydraulic pipeline sealing test (72 hours leak-free), electrical control system reclaiming program pre-setting, and 100-hour simulated full-load trial run, ensuring no faults during on-site installation.

On-site, only three steps are needed for commissioning: first, modular unit splicing, with high-strength bolts (M36, torque 2200 N·m) connecting bucket wheel module and slewing module, left and right track chassis parts, 3 people cooperating 3 hours to complete; second, hydraulic pipeline and electrical plug final docking, using quick-connect fittings + color-coded anti-error design, with different interfaces marked with corresponding scenario parameters, time ≤1.5 hours; third, universal parameter fine-tuning, calibrating bucket wheel reclaiming height and slewing angle via laser positioner to adapt to on-site stockpile layout at the project, time ≤1 hour. An experienced team can complete all installation, debugging, and commissioning within 1.5 days, 50% shorter than industry average, adapting to different installation capability differences of global customers.

ZOOMRY provides multi-language technical manuals including reclaiming precision calibration guides, highlighting key and difficult operations; equipped with 24-hour online technical support, through video guidance assisting in resolving installation queries without requiring professional heavy equipment installation teams.

Technical Parameters

| Item | Specification Parameters |

|---|---|

| Equipment Positioning | Track-Type Precise Reclaiming Dedicated Bucket Wheel Reclaimer |

| Rated Handling Capacity (m³/h) | 500-3000 |

| Overall Machine Weight (t) | 65-750 |

| Overall Machine Power (kW) | 166-1410 |

| Bucket Wheel Configuration | 8-12, diameter 5254-8200 mm, single bucket capacity 0.25-0.71 m³ |

| Bucket Wheel Speed (r/min) | 2-6 (Adjustable for Precise Reclaiming) |

| Bucket Wheel Drive Power (kW) | 75-1100 |

| Slewing Angle | Reclaiming Arm ±65-360°, Discharge Arm Relative to Reclaiming Arm ±90-±105° |

| Operating Height (m) | Upward Digging 15, Downward Digging 1 |

| Reclaiming Conveyor Belt | Width 1200-1600 mm, Belt Speed 2.5-3.0/5.0 m/s (Synchronized with Reclaiming Rhythm) |

| Track Travel | Speed 0-2 km/h (Operation 0.51 km/h, Transition 0-2 km/h), Drive Form Hydraulic Motor + Reducer/Motor Reducer, Ground Pressure 125-193 kPa |

| Electrical Control System | 15-Inch HMI Touch Screen, Multi-Language Support, PLC Full Automatic (Reclaiming Path Planning)/Remote/Manual Three Modes |

| Protection Rating | IP65 (Electrical Control Cabinet), IP55 (Motor) |

| Applicable Ambient Temperature (℃) | -30~60 (Resistant to Extreme Climates) |

| Adapted Material Range | Power Plant Coal, Mine Ore, Aggregates, Coal Gangue, and Other Bulk Materials |

| Optional Configurations | Laser Level Meter (Reclaiming Precision Calibration), Bucket Wheel Wear-Resistant Coating, Conveyor Belt Rain Cover, Low-Temperature Hydraulic Oil Heating System, Central Control Linkage Module |

Choosing ZOOMRY

Core Customer Value

- Precision Optimization: Reclaiming Deviation ≤3%, far superior to industry average, reducing material mixing and improving material utilization value;

- Scenario Adaptation: Low ground pressure design requires no site modification, reducing upfront investment; 360° slewing + track travel covers large-range stockpiles, single unit can replace multiple fixed reclaimers, lowering equipment investment;

- Worry-Free Operation and Maintenance: High-wear-resistant components extend replacement cycles, reducing maintenance costs by 50% compared to ordinary reclaimers; annual failure rate <0.5%, significantly lowering downtime losses; modular design shortens maintenance time by 40%.

Comprehensive Service Support

- Technical Support: Providing multi-language dedicated technical documents for reclaiming (including operation manuals, precision calibration guides, troubleshooting manuals), content covering different scenario reclaiming parameter settings, low-temperature environment maintenance points; 24-hour online technical consultation, engineer response time not exceeding 3 hours, assigned personnel with 8 years of precise reclaiming equipment service experience, familiar with high dust, high load scenario pain points;

- Spare Parts Assurance: Relying on efficient global supply chain, pre-stocking bucket wheel blades, slewing bearings, hydraulic filter elements, and other core spare parts; after customer demand, rapid shipment via international logistics, conventional spare parts delivery cycle 5-10 days; for key customers, providing "advance spare parts planning service"—formulating replenishment plans according to reclaiming intensity and vulnerable parts cycles to avoid reclaiming interruptions;

- Specialized Training: Conducting "precise reclaiming operation specialized training" (online + offline), content including reclaiming precision calibration methods, different material parameter optimization, emergency fault handling, ensuring customer teams proficiently master core precise reclaiming skills, adapting to continuous operation needs.

ZOOMRY

ZOOMRY