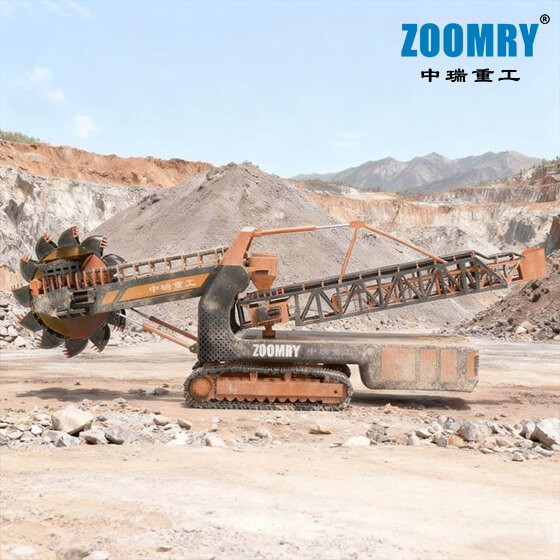

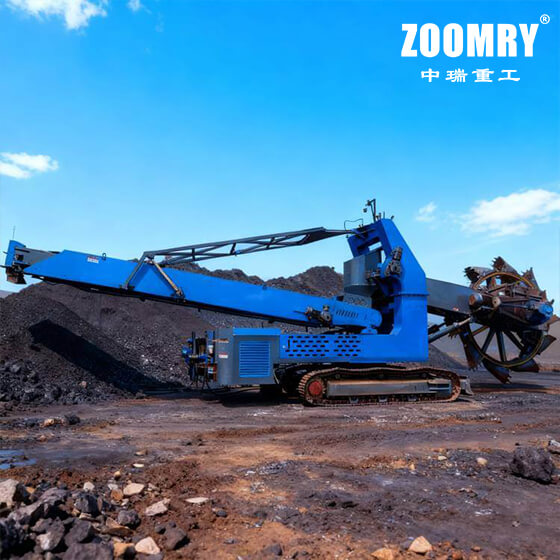

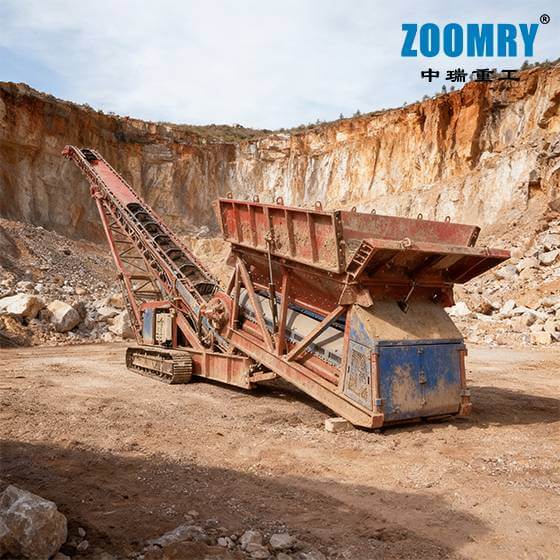

The Mobile stacker Reclaimer from ZOOMRY is a "flexible mobility + integrated stacking and reclaiming" core equipment specially crafted for global multi-scenario bulk material processing, with a wide handling capacity range of 500-3000 m³/h at its core, equipped with 8-12 customized bucket wheels (diameter 5254-8200 mm), fusing a hydraulic-driven track system (ground pressure 125-193 kPa) and ±65-360° full-domain slewing mechanism. It can flexibly move across multiple scenarios without fixed operating points, synchronously completing bulk material stacking and reclaiming. Through CE and EAC international certifications, it excels with "high mobility flexibility, superior stacking and reclaiming efficiency, broad scenario adaptability" as its core advantages, becoming the preferred choice in the field of multi-scenario bulk material processing; it can also serve as supplementary equipment for Bucket Wheel Stacker Reclaimers, meeting the dual demands of global industries for "flexibility + scalability" in bulk material processing.

Product Core Positioning

The core competitiveness of the mobile stacker Reclaimer from ZOOMRY lies in breaking through the industry pain points of traditional fixed equipment "limited operation range" and ordinary mobile equipment "insufficient stacking and reclaiming efficiency," through the deep integration of "track mobility - bucket wheel stacking and reclaiming - slewing coordination," achieving an operation mode of "single unit covering multiple stockpiles, rapid switching across different scenarios"; it simultaneously considers international compliance and long-term durability, reinforcing the core positioning of "mobile bucket wheel machine" and "movable bulk material processor," adapting to the diverse bulk material processing needs globally.

Core Technology of Mobile Stacker Reclaimer

All-Terrain Mobility Technology

The equipment is equipped with a drive system primarily "hydraulic motor + reducer" (optional motor reducer), innovating precise stepless speed adjustment technology, subdivided into "operation mobility (0.51 km/h)" and "transition mobility (0-2 km/h)" dual modes: low-speed mobility during operations precisely controls stacking and reclaiming positions, avoiding material spillage; high-speed repositioning during transitions improves stockpile switching efficiency by 60% compared to traditional equipment. The track plates use 600 mm wide Q690 high-strength alloy steel, after carburizing and quenching treatment (hardness HRC58-62), with wear resistance 80% higher than ordinary tracks, capable of resisting scratches from sharp materials, adapting to long-term mobility across multiple scenarios, with service life exceeding 12000 hours.

The 125-193 kPa low ground pressure design, through the optimized combination of wide tracks and lightweight chassis, achieves even weight distribution: during operations on soft sites with bearing capacity ≤200 kPa, it avoids unit entrapment; on hardened ground, no additional reinforcement is needed, reducing site modification investments; during stacking along stockpile edges, it reduces pile compression and collapse, controlling stockpile layer thickness deviation within 5%. The track tensioning system adopts hydraulic automatic adjustment technology, dynamically adjusting tension force according to ground hardness (8-10 kN on soft ground, 12-15 kN on hard surfaces), adapting to mobility demands across different scenarios without manual intervention, ensuring stable and deviation-free mobility.

Stacking and Reclaiming Coordination Core

With "mobile-stacking and reclaiming rhythm synchronization" as the design core, the bucket wheel and conveyor form efficient coordination: 8-12 bucket wheels are flexibly configured according to handling capacity (8-10 for 500-1500 m³/h, 10-12 for 1500-3000 m³/h), single bucket capacity 0.25-0.71 m³, 2-6 r/min adjustable speed precisely adapts to mobile operations—during reclaiming, speed is synchronously lowered (2-4 r/min) to ensure capture without omission; during stacking, speed is synchronously raised (4-6 r/min), combined with 2.5-5.0 m/s adjustable belt speed, with stacking and reclaiming efficiency 35% higher than fixed bucket wheel machines.

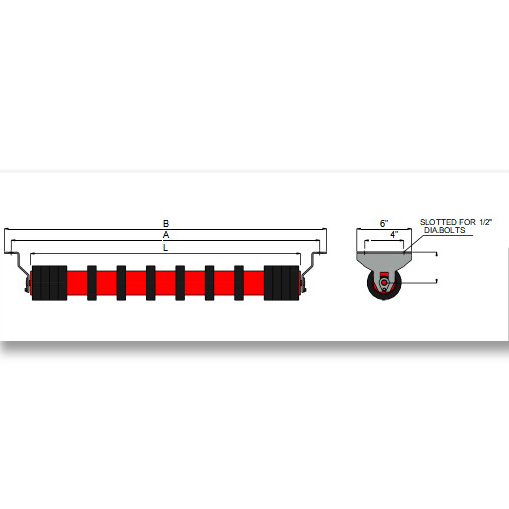

The bucket wheel blades use 16 mm thick Mn13 wear-resistant manganese steel + 3 mm tungsten carbide coating; during reclaiming, they resist hard material impacts, during stacking, they extend service life due to no violent material collisions; the inner side is fitted with PTFE anti-stick guide plates, material residue rate ≤0.2%, avoiding mixing of different batch materials during mobile operations. The Conveyor Belt uses PVG flame-retardant wear-resistant rubber belt (14 mm thickness), with longitudinal tensile strength of 2000 N/mm; the surface diamond anti-slip pattern improves anti-slip performance by 50%, coping with slight vibrations in mobility; both sides with 400 mm high rubber skirts + soft sealing strips, with side leakage rate ≤0.5% in stacking and reclaiming operations, balancing efficiency and material recovery.

Full-Domain Coverage Design

Through flexible adjustment of "slewing angle + operating height," it achieves full-domain coverage in multi-scenarios: the bucket wheel reclaiming arm supports ±65-360° full-angle slewing; during mobility, it can adjust stacking and reclaiming direction through slewing without frequent track repositioning; a single unit covers an 80 m diameter stockpile area, reducing equipment repositioning by 90% in multi-stockpile scenarios; the discharge arm relative to the reclaiming arm ±90-±105° adjustment, paired with 15 m upward digging height (universal for stacking/reclaiming) and 1 m downward digging height (exclusive for reclaiming), can achieve diverse operation needs such as layered stacking and bottom clearing without additional stacking equipment.

The slewing drive adopts dual hydraulic motor linkage technology, with output torque of 10000 N·m; during frequent slewing in mobile operations, it maintains precision ≤0.3°, ensuring precise reclaiming positions and neat stacking boundaries; the slewing bearing selects four-point contact ball bearing (diameter 3-5 m), with load capacity of 1800 kN, capable of withstanding radial loads from mobile reclaiming and overturning moments from stacking; the surface "nitriding + double-lip sealing" design resists dust and corrosion, adapting to outdoor multi-scenario operations, with service life exceeding 60000 hours.

Core System Assurance

Mobile Drive and Chassis System

The mobile drive system is equipped with a graded hydraulic pump station (adapted to overall machine power of 166-1410 kW per specifications), innovating dual-circuit independent oil supply design: one circuit exclusively drives track travel, achieving precise ±0.1 km/h fine-tuning through stepless speed valves, ensuring synchronization with bucket wheel stacking and reclaiming rhythm; the other drives the slewing mechanism, avoiding mutual interference between mobility and slewing actions. Oil tank capacity 1200-2500 L, quadruple high-precision filtration (5 μm precision) ensures hydraulic oil cleanliness at NAS 7 level, with system annual failure rate below 0.3%; in low-temperature environments, built-in heating device achieves ≤30 seconds start response at -30℃, adapting to cold zone operations.

The track chassis frame uses Q690 high-strength alloy steel welding, optimized through finite element analysis for mobile load structures; under vibration loads from uneven ground during mobility, frame deformation ≤2 mm, ensuring stable coordination of bucket wheel and conveyor belt; track drive wheel and guide wheel are integrally forged steel, with tooth surface quenching hardness HRC60, withstanding instantaneous shocks from frequent starts and stops in mobile operations, with tooth wear ≤0.1 mm/1000 hours, extending maintenance cycles.

Intelligent Electrical Control System

The electrical control system centers on "convenience of mobile stacking and reclaiming," with 15-inch high-definition HMI touch screen supporting multi-language switching, interface focusing on "one-click coordination of mobile-stacking and reclaiming parameters," capable of storing 5 groups of multi-scenario operation programs; during switching, it directly invokes preset parameters without repeated debugging, adapting to rapid response in different scenarios.

The system supports three control modes, all optimized for mobile operations:

- PLC full automatic mode: Through laser level meter + infrared positioning sensor collecting stockpile height and equipment position data, automatically plans mobile paths and stacking/reclaiming rhythms, with stacking and reclaiming volume deviation ≤3%, achieving "unattended" mobile operations;

- Remote control mode: 200 m industrial-grade wireless remote controller (IP67 anti-interference compliant), allowing operators in safe areas to real-time fine-tune track speed and bucket wheel speed during stacking to adjust discharge arm angle for pile height control, during reclaiming to fine-tune movement direction to avoid impurities;

- Manual mode: Quick switch in emergencies, equipped with "mobile operation warning" function; when detecting speed and speed mismatch, it automatically prompts adjustment to ensure safety and controllability.

Transportation, Installation, and Compliance Quality Control

Global-Adapted Modular Transportation

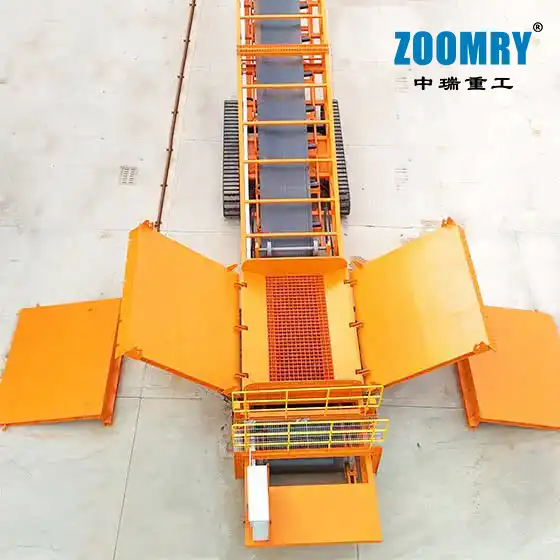

For the pain points of cross-border transportation and on-site installation differences, the equipment is disassembled into "bucket wheel reclaiming module, track mobility module, slewing drive module, electrical control module, hydraulic module" 5 standard units, all strictly adapted to 40-foot high containers: the track mobility module is divided into left and right two parts (single weight ≤45 tons), height ≤2.4 m after hydraulic folding, movable via ordinary forklifts at the project site; the bucket wheel reclaiming module weighs ≤32 tons after arm folding, the slewing drive module integrates stacking and reclaiming drive unit (weight ≤28 tons); electrical control and hydraulic modules are waterproof boxes, requiring no special transport permits.

Core mobile components (track plates, hydraulic motors) undergo "anti-rust + anti-collision" double-layer packaging before leaving the factory to avoid precision damage from transport vibrations; compared to traditional equipment, cross-border logistics costs are reduced by 40%, adapting to global multi-region logistics conditions.

High Pre-Assembly for Rapid Commissioning

Before leaving the factory, the equipment completes 85% pre-assembly, focusing on "mobile-stacking and reclaiming coordination function": splicing and no-load travel testing of track mobility module, bucket wheel-conveyor stacking and reclaiming coordination debugging, hydraulic pipeline 72-hour sealing test, and 100-hour full-load trial run of "simulated multi-scenario mobile stacking and reclaiming," ensuring no faults during on-site installation.

On-site deployment only requires three steps: first, high-strength bolt splicing of modular units (3 people 3 hours); second, hydraulic and electrical quick-connect docking (with anti-error design, ≤1.5 hours); third, laser calibration of mobile stacking and reclaiming parameters (≤1 hour). An experienced team can complete all deployment within 1.5 days, 50% shorter than industry cycle, adapting to rapid commissioning needs.

International Compliance and Specialized Quality Control

The equipment passes EU CE certification and Russian EAC certification, completing 14 specialized safety tests for mobile bulk material equipment, allowing direct entry into global mainstream markets; it complies with ISO 9001/14001 systems, with full traceability of the production process; each process has detailed quality records.

Quality testing focuses on mobile stacking and reclaiming core: the mobility system undergoes 500-hour multi-scenario mobility test (track plate wear ≤0.5 mm, deviation ≤5 mm/100 m); the stacking and reclaiming coordination system undergoes 100-hour full-range mobile stacking and reclaiming test (reclaiming deviation ≤2%, stacking layer thickness deviation ≤5%); the hydraulic and electrical control system undergoes low-temperature startup, high-pressure sealing, and anti-interference tests, with normal function and no failures. Each unit must pass 18 strict tests before leaving the factory, and is delivered only after qualification.

Technical Parameters

| Item | Specification Parameters |

|---|---|

| Equipment Positioning | Hydraulic-Driven Mobile Bucket Wheel (Integrated Stacking and Reclaiming) |

| Rated Handling Capacity (m³/h) | 500-3000 |

| Overall Machine Weight (t) | 65-750 |

| Overall Machine Power (kW) | 166-1410 |

| Bucket Wheel Configuration | 8-12, diameter 5254-8200 mm, single bucket capacity 0.25-0.71 m³ |

| Bucket Wheel Speed (r/min) | 2-6 (Self-Adaptive for Mobile Stacking and Reclaiming Operations) |

| Bucket Wheel Drive Power (kW) | 75-1100 |

| Slewing Angle | Reclaiming Arm ±65-360°, Discharge Arm Relative to Reclaiming Arm ±90-±105° |

| Operating Height (m) | Upward Digging 15 (Universal for Stacking/Reclaiming), Downward Digging 1 (Exclusive for Reclaiming) |

| Reclaiming Conveyor Belt | Width 1200-1600 mm, Belt Speed 2.5-5.0 m/s (Synchronized with Mobile Stacking and Reclaiming Rhythm) |

| Track Travel | Speed 0-2 km/h (Operation 0.51 km/h, Transition 0-2 km/h), Drive Form Hydraulic Motor + Reducer/Motor Reducer, Ground Pressure 125-193 kPa, Track Plate Width 600 mm (Q690 High-Strength Steel) |

| Electrical Control System | 15-Inch HMI Touch Screen, Multi-Language Support, PLC Full Automatic (Mobile Stacking and Reclaiming Coordination)/Remote/Manual Three Modes |

| Protection Rating | IP65 (Electrical Control Cabinet), IP55 (Motor) |

| Applicable Ambient Temperature (℃) | -30~60 (Resistant to Extreme Climates) |

| Adapted Material Types | Mine Ores, Power Plant Coal, Port Bulk Materials, Aggregates, etc. |

| Optional Configurations | Laser Level Meter (Mobile Stacking and Reclaiming Calibration), Bucket Wheel Wear-Resistant Coating, Conveyor Belt Rain Cover, Low-Temperature Hydraulic Oil Heating System, Central Control Linkage Module |

Choosing ZOOMRY

Core Customer Value

- Multi-Scenario Adaptation Reduces Costs: Low ground pressure requires no site modification, adapting to multiple operation environments, reducing site preparation investment; single unit covers 80 m stockpile, replacing multiple fixed units, lowering initial investment;

- Mobile Coordination Improves Efficiency: "Mobile-stacking and reclaiming" integrated design reduces equipment switching and repositioning time, significantly improving operation efficiency; fast transition speed, 40% higher equipment utilization in multi-stockpile scenarios;

- Worry-Free Operation and Maintenance Optimization: High-wear-resistant components extend replacement cycles, hydraulic and electrical control system annual failure rate <0.3%, reducing maintenance frequency; modular design shortens maintenance time by 40%, lowering downtime losses.

Comprehensive Service Support

- Professional Technical Support: Providing multi-language mobile operation dedicated technical documents, covering multi-scenario parameter settings, troubleshooting guides; 24-hour online technical consultation, engineer response time not exceeding 3 hours, familiar with pain points of multi-scenario mobile operations;

- Efficient Spare Parts Assurance: Relying on global supply chain to pre-stock core spare parts; after customer demand, rapid shipment through international logistics, conventional spare parts delivery cycle 5-10 days; for key customers, providing "advance spare parts planning service," formulating replenishment plans according to operation intensity and vulnerable parts cycles to avoid operation interruptions;

- Specialized Skill Training: Conducting "mobile bucket wheel machine operation specialized training," covering matching of mobility and stacking/reclaiming rhythm, multi-scenario parameter optimization, emergency fault handling; through theory + practice, ensuring customer teams master core skills.

ZOOMRY

ZOOMRY