-

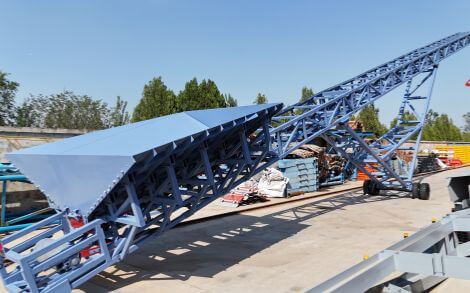

Mobile Truck Unloader Conveyor: An Efficient Transfer Solution for Global Bulk Material Unloading

In the global bulk material handling industry, the efficiency and stability of the unloading and transfer process directly determine the smoothness of the entire production chain. Whether it is ore turnover in mining, bulk cargo distribution in ports, or aggregate transport in the construction materials industry, traditional unloading methods often face challenges: excessive reliance on manual coo… -

What is a Hopper Feeder Conveyor?

Also known as grasshopper conveyor and portable stacker, the hopper feeder conveyor is a bulk material equipment integrating material receiving, quantitative conveying, and multi-terrain movement. It can work efficiently with belt conveyors, mobile ship loaders, etc., and is suitable for global bulk material handling scenarios such as mining, ports, chemical engineering, and power generation.… -

Capacity Improvement Solution for Limestone Radial Stackers

As a core raw material for cement production, limestone brings many challenges to most enterprises in the stacking process: the existing limestone radial stackers are limited by their designed capacity and cannot match the combined output capacity of the crushing system, forcing the crushers to operate at reduced capacity; the equipment consumes excessive energy during operation, with power consum… -

How to Use Telescopic Shiploaders for Iron Ore Bulk Material Conveying

transportation and port transshipment: high-load equipment vulnerability, difficulty adapting to multiple ship types, high material loss from spillage, and frequent failures in complex environments. Traditional fixed shiploaders, due to insufficient flexibility and limited adaptability, struggle to meet the high-efficiency and low-loss requirements of modern iron ore bulk material conveying. The t… -

What Are the Application Scenarios Suitable for Mobile Stacker Conveyors

In the global bulk material handling system, from the transfer and storage of industrial raw materials to the circulation of civil materials, "scenario adaptability" directly determines the efficiency and cost of bulk material handling. As a key piece of equipment in bulk material conveying systems, mobile stacker conveyors, with the combination of movable chassis and adjustable stacking mechanism… -

Port Bulk Material Conveying Solution Using Multiple Hopper Feeders

In the global field of port bulk material conveying, "efficient connection, low consumption & environmental protection, and flexible adaptation" are the core demands of enterprises. Whether it is the full link of unloading-stockpiling-loading for bulk materials such as coal and ore, the dynamic adaptation of ships of different tonnages, or the challenge of height difference operations caused by po… -

Cost-Effective and High-Efficiency 500tph Radial Stacker

In the bulk material handling process of mines, ports, and aggregate plants, "high investment with low output" and "low efficiency in limited space" are two major pain points faced by global customers: traditional stacking equipment either requires high civil engineering costs to adapt to the site or slows down production due to insufficient throughput. The 500tph radial stacker developed specific… -

2025 Global High-Rated Mobile Truck Unloader Conveyor

Traditional unloading equipment faces challenges in various scenarios: in mines, it struggles to adapt to rugged terrain and complex road conditions, causing frequent congestion during unloading; at ports, space constraints limit single-model unloading equipment from flexibly handling light trucks, heavy trucks, semi-trailers, and other multi-tonnage vehicles, leading to low site utilization; in r… -

Fully Adaptable Mobile Shiploader for Mines and Ports

In the global bulk material handling industry, the rough terrain of mines, the demand for multiple ship types in ports, and the differences in material characteristics of sand and gravel yards have plunged enterprises into a dilemma of "difficult equipment selection, high costs, and low efficiency". If specialized transfer equipment is configured for mines, it is necessary to replace it with a shi…

ZOOMRY

ZOOMRY