Product Description

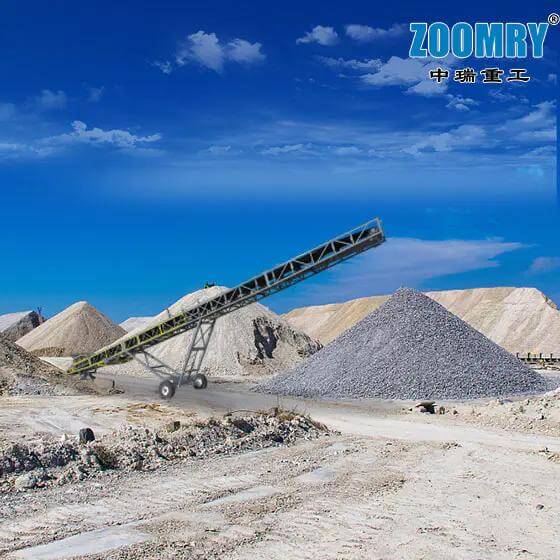

The long-distance curve conveyor is a conveyor developed to adapt to complex terrain and long-distance transportation needs in the wild. It can be installed following the undulations of the ground and avoid obstacles and buildings through curved turns. The length of a single conveyor can reach more than 15km.

Long-distance curved belt conveyors are widely used in mines, docks, cement plants, sand and gravel aggregates, container terminals, and various raw material factories. They are used to replace conventional multiple belt conveyor overlapping or road transportation.

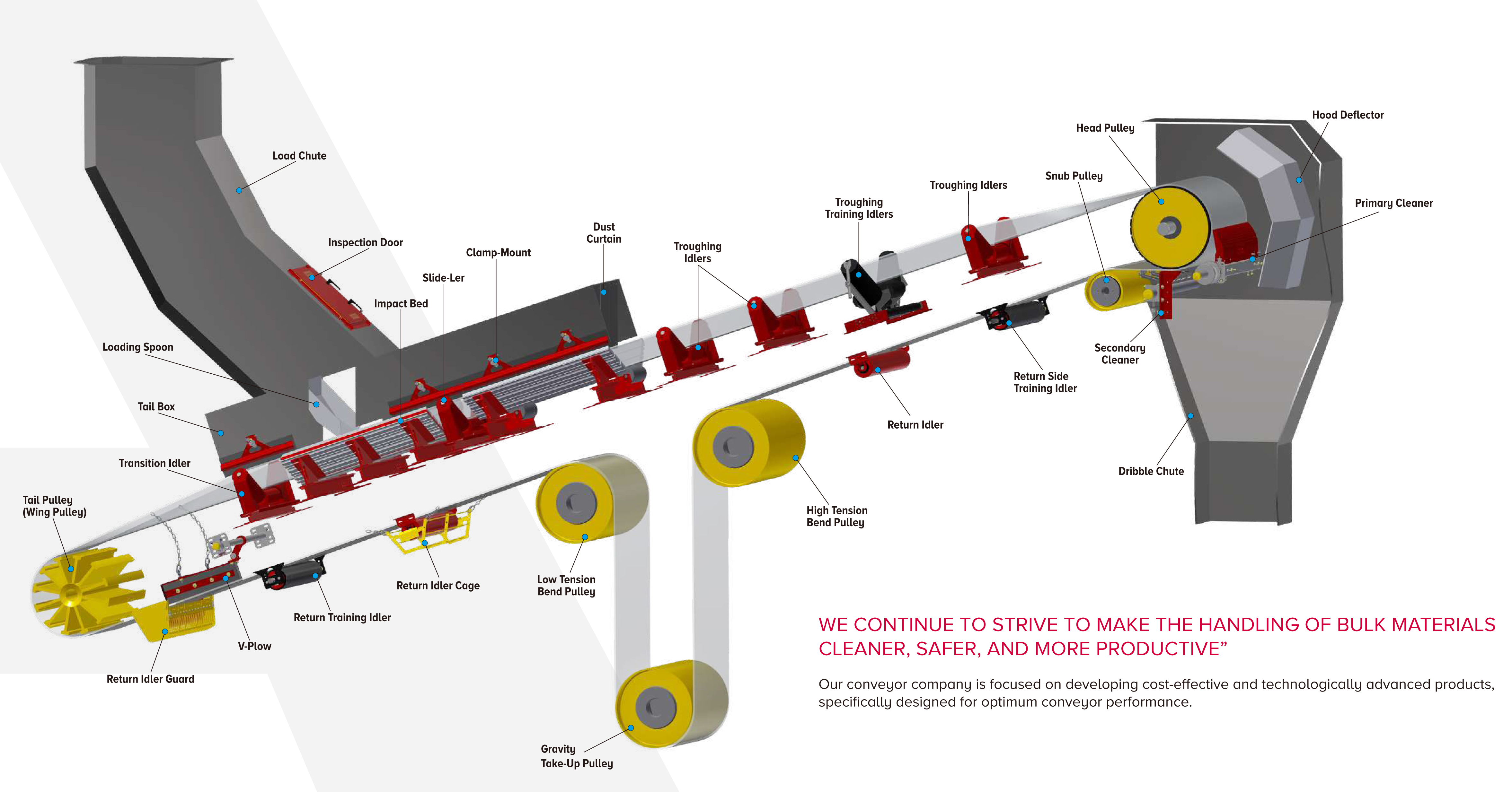

Details

Belt Sway Switch

Detect whether the belt is deviating and send out a slight alarm or shutdown signal. Deviation will damage the belt and cause safety accidents. Deviation switches need to be purchased and installed in pairs

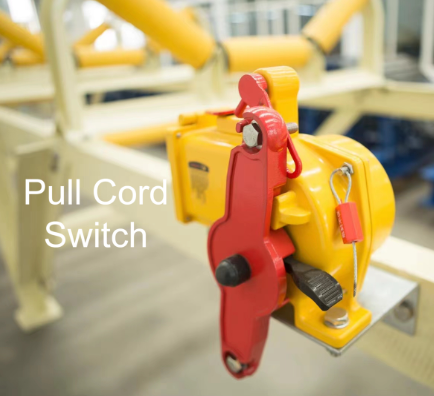

Pull the wire rope to realize the switch action, which is used for emergency shutdown. It is a safety switch and is arranged along the entire length of the fuselage.

When an emergency occurs on the belt conveyor, the conveyor can be stopped urgently at any position. There are single-sided and double-sided arrangements. They are generally used in conjunction with walkways.

Zero Speed Switch

Detect whether the belt is slipping with the head roller. After slippage occurs, the Conveyor Belt speed will decrease. When the transport volume is overloaded, the belt tension is insufficient, or the rubber layer of the driving roller is worn out, slippage may easily occur. The conveyor belt speed can be monitored (also the rotational speed is calculated) or the drum rotation speed can be monitored.

If the belt conveyor in the stacker encounters an unexpected situation, such as a power outage or a broken wire rope, the stacker has a self-protection function:

1. The winch motor has a self-locking function of 0.01 seconds when the power is cut off

2. The stacker has 2 mechanical mechanisms If stuck, the internal unit will not slip to the bottom all at once. There are two designs in the middle to prevent jamming.

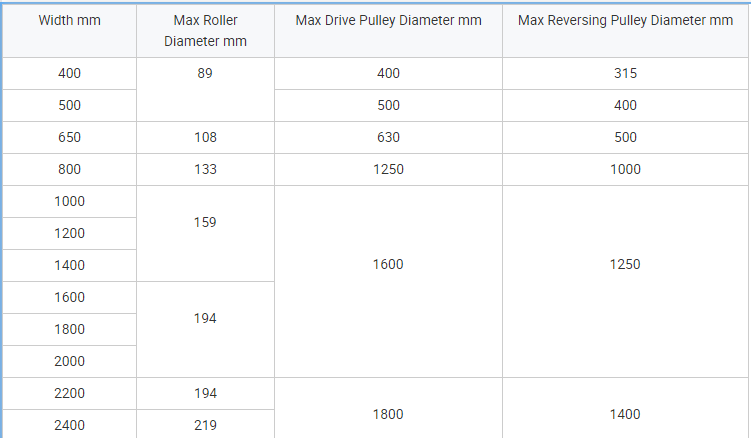

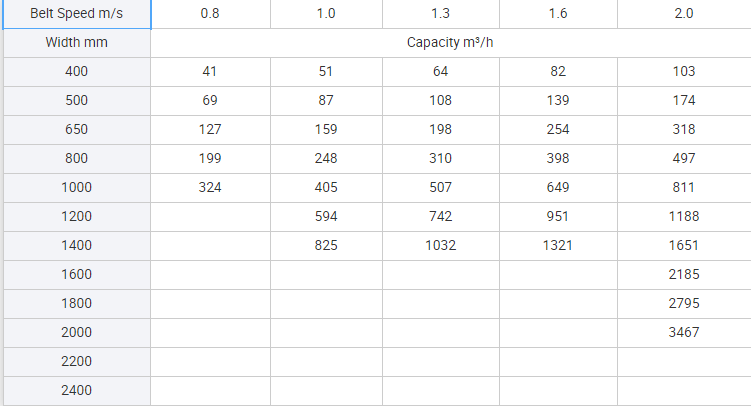

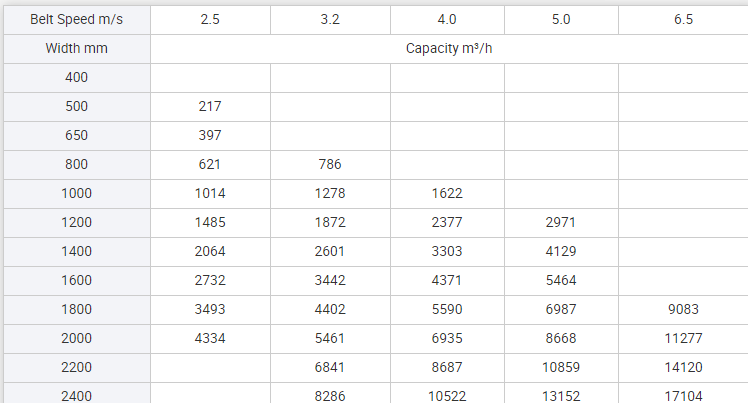

Specification

Advantage:

1.Environmentally friendly, there is no dust pollution and minimal noise during long-distance conveyor transportation.

2.Energy saving, the power source is clean electric energy, there is no air pollution and no waste gas is produced.

3.It is safe, does not occupy local transportation resources, and avoids various safety hazards caused by car transportation.

4.Curved transportation can better adapt to local geographical conditions, avoid complex road sections, avoid buildings and roads, etc., which is conducive to project approval and later operation management.

Application and cases

Brazil Steel Raw material plan

Capacity: 2*5000t/d

Material type: coal

Angle: 31°

Belt width: 1000mm

Philippines Power Plant.2018

Belt conveyor system

Capacity:4*1800t/h

Belt width: 1200mm

Video

For belt conveyor and mobile telescopic stackers, if to make the machine running for long time, client need to do the vulcanizing at site.

We can supply the vulcanizing machine with the telestacker or long distance belt conveyor system.

The site vulcanizing work can be done with the following steps:

How to do the site Conveyor belt vulcanizing

ZOOMRY

ZOOMRY