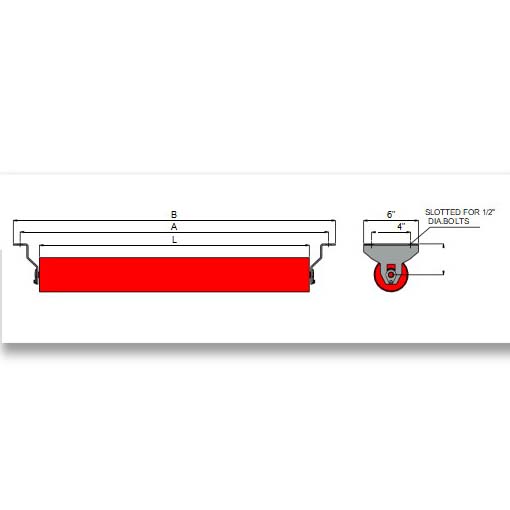

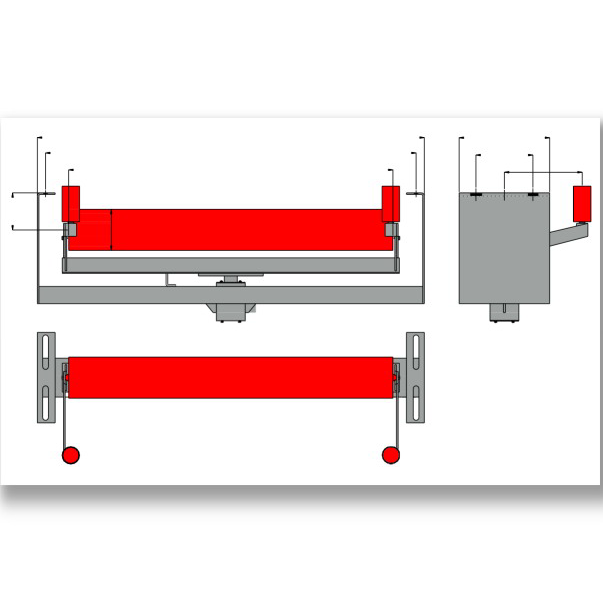

Specification:

Capacity

300-500m3/h

motor Power

120-150kw

Gauge

5-6m

Product information:

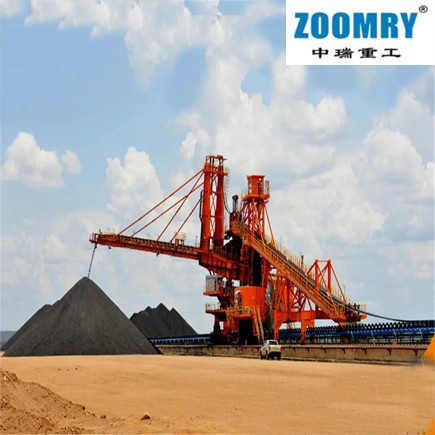

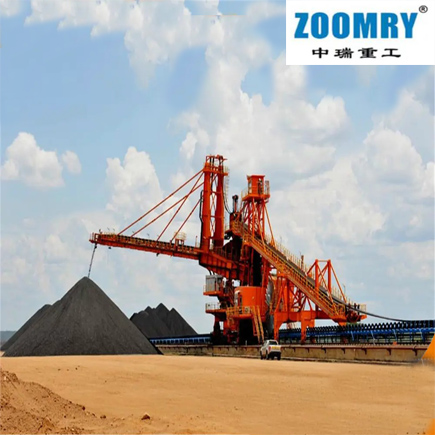

The Mobile Chain Bucket Unloader is an overhead unloader that discharges particle-mass material from the rail using a special chain bucket unloader apparatus. The materials could include sand, gypsum, shale, iron ore, etc. The Mobile Chain-type bucket unloader is made up of many pieces, including a driver's compartment with air conditioning, a chain lighting mechanism, a traveling mechanism, a belt-type conveyor system, a dust cleaning device, and an electric control system.

This system is environmentally favorable because the dust collection unit is mounted above the belt conveyor. As a result, industries are abandoning excavator and dust-remover systems too rapidly. The material conveying equipment used by the mining industry might be the bulk material handling equipment.

Coal, petrochemicals, steel, cement, metallurgy, power plants, etc.

ZOOMRY

ZOOMRY