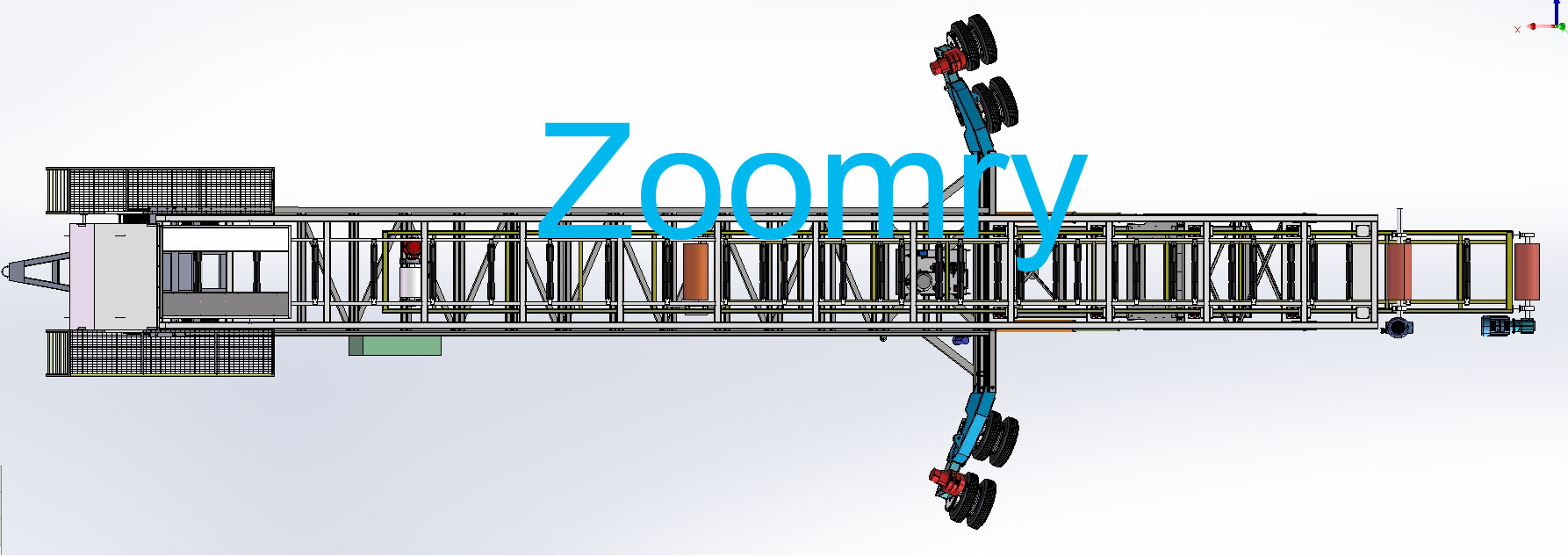

Mobile stacker Conveyor Description

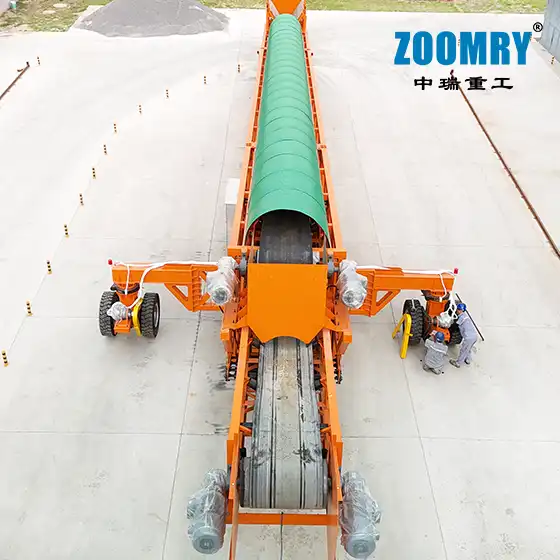

The mobile stacker conveyor features a heavy duty truss design with radial landing gear, heavy duty aisle frame construction, radial chassis and can be powered by electric, hydraulic or diesel power modules. mobile stacking conveyor's radial stacking capability allows users to greatly improve performance and reduce the cost of material handling on site. Ideal for mulch, compost and fuel chip storage, the mobile stacking conveyor can be adapted to any size operation. The ability to store large volumes of material in tall, wide piles without frequent repositioning of equipment is the key to uninterrupted productivity.

Zoomry offers mobile stacking conveyors to provide our customers with material handling solutions for the quarrying, mining, dock and rail transportation industries. The flexibility and efficiency of this mobile stacking conveyor means it can be used for many long and short term applications with a high resale value. The unit comes fully assembled and is a towable road transport product or can be broken down and loaded into three 40 foot containers for efficient global transport.

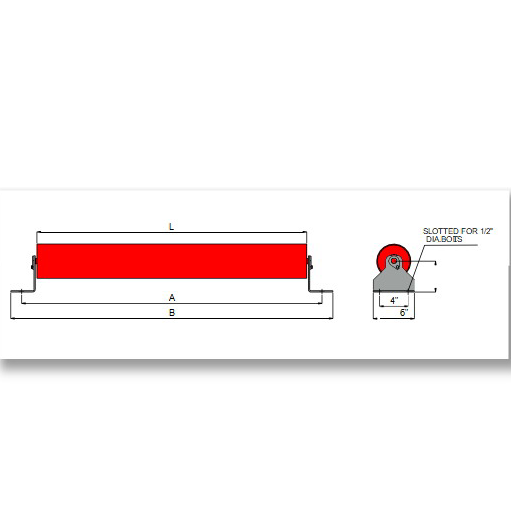

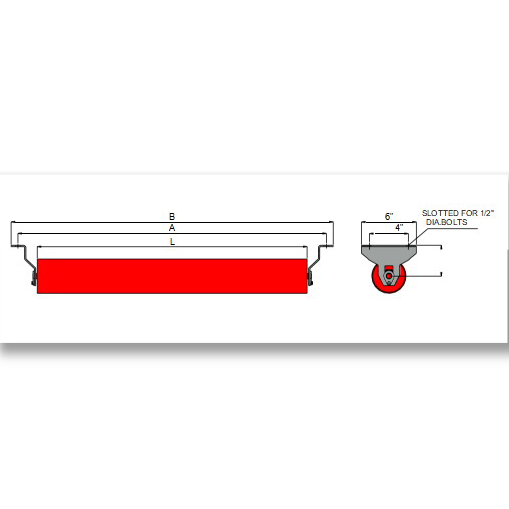

Stacking Material, typically aggregates, is piled on conveyors for subsequent usage. The conveyors can generate conical piles for additional storage by pivoting about their tail terminals. Moreover, they can be raised and lowered manually or mechanically.

Application:

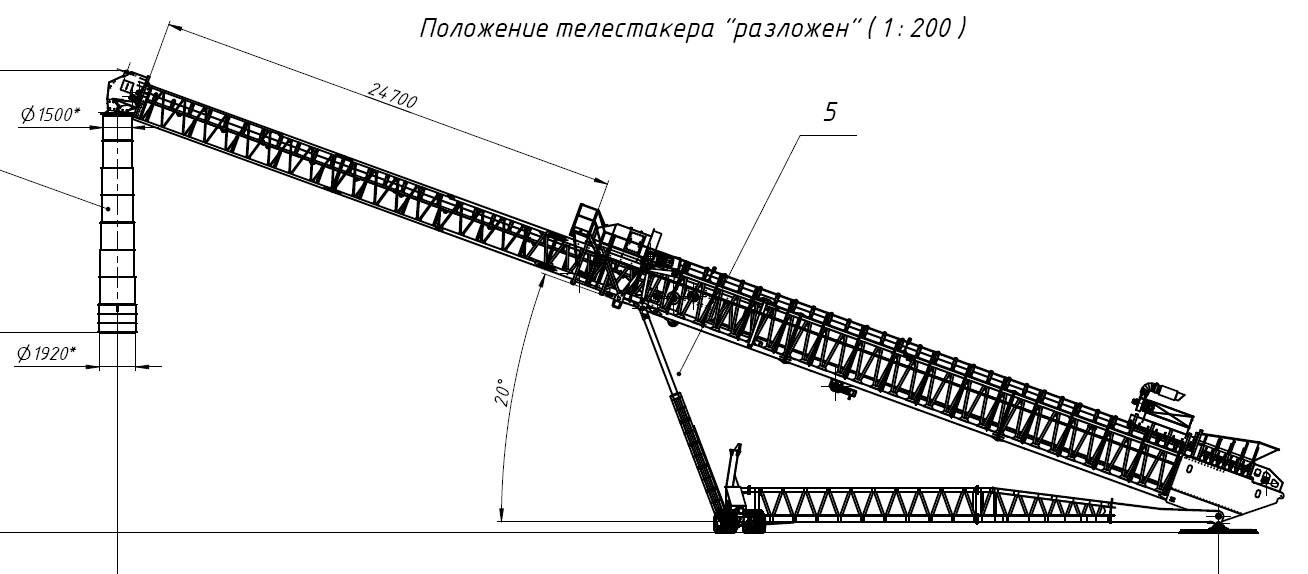

It is used for flexible mobile stacking in various occasions, and the stacking height can reach 20m. Because the stacker is movable, rotatable and retractable, it greatly increases the stacking capacity and efficiency.

Advantages of mobile stacke:

The stacking efficiency is high, and the rotary telescopic stacking can be realized;

Compared with the conventional loader, the stacking material is only 5m-8m, and the stacking height can reach 20m, which greatly improves the utilization rate of the site;

Easy to move, after completing the stacking in one area, it can be moved to other sites to continue working;

Compared with the conventional large-scale stacker-reclaimer and dumper, the equipment is highly cost-effective;

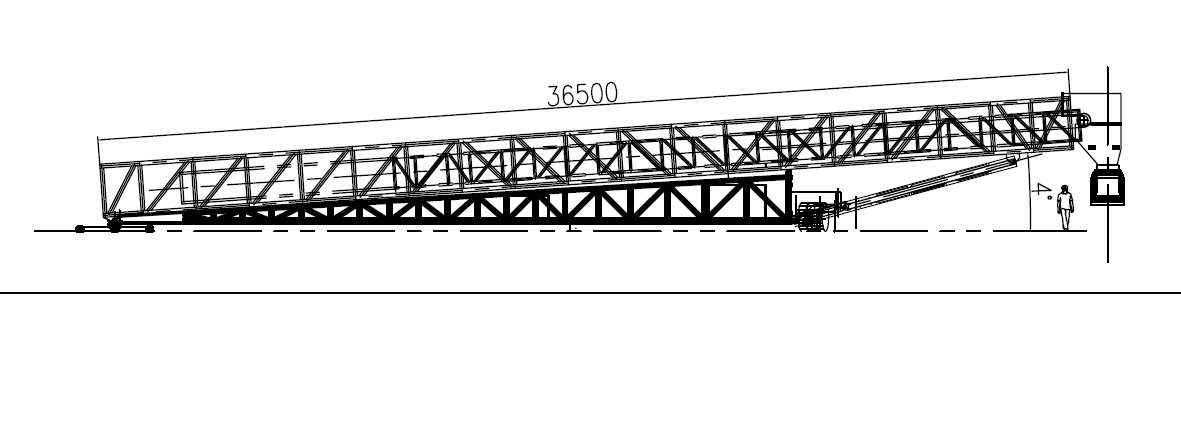

Specification:

| Model | Width/mm |

Maximum Capacity m3/h |

Speed m/s |

Standard length/m |

Maximum angle |

Telescopic length/m |

| ZR80SF | 800 | 500 | 2.5 | 30/40/50 | 20° | 10-20 |

| ZR100SF | 1000 | 850 | 2.5 | 30/40/50 | 20° | 10-20 |

| ZR120SF | 1200 | 1500 | 3.15 | 30/40/50 | 20° | 10-20 |

| ZR140SF | 1400 | 2100 | 3.15 | 30/40/50 | 20° | 10-20 |

| ZR160SF | 1600 | 3500 | 4 | 30/40/50 | 20° | 10-20 |

The above are our standard models, we can customize production according to customer needs.

We have a long and solid cooperation with SEW and Flnders and look forward to your inquiry.

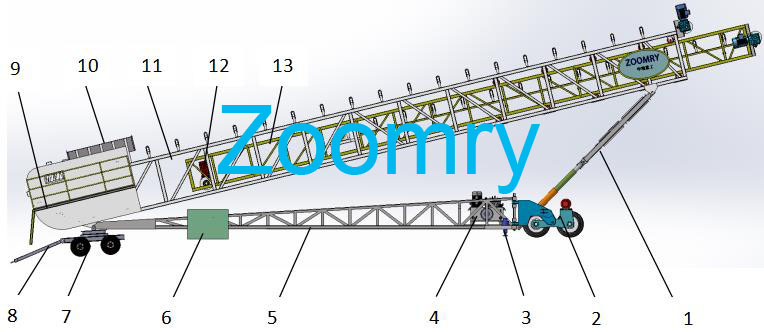

Structural composition of stacker:

1-Hydraulic lifting system 2-Front wheel walking device 3-Hydraulic outriggers 4-Hydraulic station system 5-Base 6-Electrical control box 7-Tail wheel rotation device 8-Tow bar 9-Maintenance platform 10-Hopper 11 -Main belt conveyor 12-Wire rope traction device 13-Telescopic belt conveyor

More details:

The included angle of the stacker can be controlled between 4 degrees and 20 degrees.

ZOOMRY

ZOOMRY