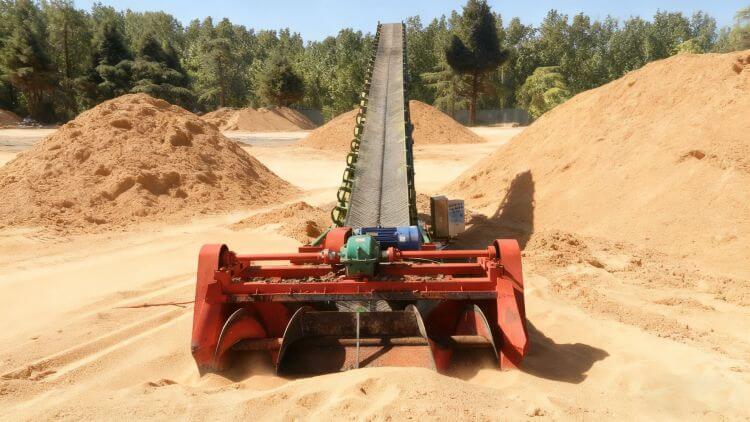

The ZOOMRY Tracked spiral scraper conveyor is a core equipment designed specifically for bulk material handling in complex terrains, with a 400 mm wide dual-configuration tracked chassis (rubber or steel optional) as its key breakthrough, integrating the flexible operational characteristics of sand scrapers with the weather-resistant performance of muck scrapers, achieving a full capacity range of 100-2000 tph. Equipped with a 500-800 mm outer diameter spiral scraper system and an 800-1600 mm wide Conveyor Belt, it supports 100-meter wireless remote control operation, enabling stable bulk material scraping and conveying in rugged terrains such as soft mine sites or open stockyards without requiring site leveling. Certified by international standards such as CE and EAC, the equipment is the preferred solution for “strong terrain adaptability, flexible operation, and wear resistance” in gravel scraping and open-pit mine bulk material handling. It can also serve as a front-end scraper for the spiral scraper conveyor for loading, enabling collaborative operations and providing efficient bulk material handling solutions for complex terrains to global clients.

Core Functions of the Tracked spiral scraper conveyor

The core competitiveness of the ZOOMRY Tracked spiral scraper conveyor focuses on “complex terrain adaptability and mobile operation stability.” Addressing the pain points of traditional wheeled scraper conveyors, such as “prone to entrapment, limited operational range, and high site preparation costs,” it resolves issues like discontinuous material scraping and difficult equipment mobility through optimized tracked structure and synergistic design, while meeting global clients’ dual demands for international compliance and equipment durability.

The 400 mm wide dual-configuration tracked chassis adapts to all complex terrains: the rubber tracks, model 4009068 with an effective length of 2.9 m, are made of high-elasticity wear-resistant material with a ground pressure of only 0.07 MPa—merely one-third that of traditional wheeled scraper conveyors—distributing the equipment’s weight evenly on soft ground (e.g., mine tailings or rain-soaked open stockyards), preventing entrapment and avoiding damage to temporary stockyard infrastructure like roads. With a minimum turning radius of 5 m, it allows flexible adjustment of scraping positions even in narrow gaps between material piles, reducing route adjustment time. The steel tracks, made of Q355B high-strength steel, model 40013554 with an effective length of 3.6 m, have carburized and quenched track plates with a hardness of HRC58-62, improving wear resistance by 80% compared to standard steel tracks, resisting scratches from sharp materials in scenarios like rocky mine stockyards or gravel yards in construction material plants. Track tension is adjusted in real-time via the hydraulic system to adapt to varying ground hardness, reducing the risk of track deviation. Both track types are paired with a “hydraulic motor + planetary reducer” drive combination, with a single motor delivering up to 3500 N·m of output torque, enabling smooth start-stop and steering even under full load. Combined with chassis hydraulic shock absorbers, the equipment maintains a body vibration amplitude within 3 mm during operations on slopes up to 15°, ensuring scraping stability during movement and preventing material spillage.

The synergistic design of mobile scraping and conveying further expands the equipment’s operational range. Unlike fixed scraper conveyors that require “stationary operations and frequent repositioning,” this equipment adopts a “deeply integrated spiral scraper unit and tracked chassis” solution, enabling continuous scraping during track movement. The spiral system, with a 500-800 mm outer diameter and 2-3.2 m scraping width, efficiently retrieves bulk materials. Its 6-8 mm thick blades, inlaid with HRC60 hardness alloy teeth, can break up slightly caked materials like wet coal or sticky gravel in open stockyards, reducing scraping blockages. The retrieved materials are directly conveyed to downstream conveyors or silos via a 12-15 m long conveyor belt, with a 4-meter discharge height precisely matching the feed ports of mainstream transfer equipment, eliminating the need for secondary lifting. This “mobile scraping + stable conveying” model expands the operational range by twofold compared to fixed scraper conveyors, allowing a single unit to cover a 50-meter diameter operational area in open-pit mine scenarios with multiple scattered material piles, eliminating the need for frequent trailer repositioning. This increases scraping efficiency by 35% compared to traditional equipment, making it particularly suited for mining operations with “multiple material piles and complex terrains.”

The 100-meter wireless remote control system enhances operational safety and convenience. The control system, centered on “tracked movement and scraping synergy control,” is equipped with a 304 stainless steel rainproof control cabinet (IP65 protection rating) and a 100-meter wireless remote control handle, supporting full functionality including “track movement, spiral speed adjustment, conveyor belt start-stop, and emergency shutdown.” Operators can observe material pile conditions from safe areas like mine observation platforms or stockyard control rooms, adjusting equipment position and scraping parameters in real-time—for example, fine-tuning track steering via remote control to avoid single-side entrapment on soft ground or controlling slow track movement for “scraping while moving” in multi-pile scenarios, eliminating the need for close contact with the equipment, enhancing both operational safety and reducing labor costs. Additionally, the control system supports multi-language adaptation, with an interface focused on “track-scraping synergy” logic, capable of one-touch retrieval of three sets of terrain-adapted parameters (e.g., track speed for soft ground, spiral speed for hard ground), enabling operators in different global regions to quickly master operations without extensive training.

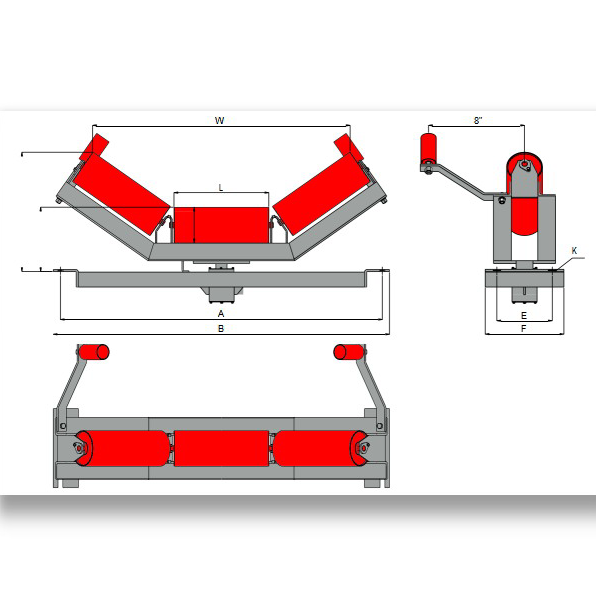

Key Components of the Tracked Spiral Scraper Conveyor

The long-term stable operation of the ZOOMRY Tracked Spiral Scraper Conveyor relies on core components designed for “track durability, ample power, and synergistic stability.” Each component undergoes complex terrain condition simulation testing and international standard verification to ensure compatibility with global multi-terrain bulk material handling needs.

The tracked chassis system’s reinforced design provides reliable support. Beyond the dual-configuration tracks, core components are optimized for wear resistance and rust prevention: track connecting pins are made of 40Cr forged material with phosphatized surfaces, improving rust resistance by 60% to prevent seizing in high-humidity mine environments; track drive and guide wheels are integrally forged steel with quenched gear surfaces (hardness HRC60), extending wear resistance to over 10,000 hours; the chassis frame is welded from Q690 high-strength alloy steel, optimized for load-bearing structure via finite element analysis, with frame deformation under full load limited to ≤2 mm, ensuring synergistic stability between the spiral and conveyor belt. The track drive hydraulic system’s core is an 11-18.5 kW hydraulic pump station, matched to track type and spiral specifications (11 kW for rubber tracks, 15-18.5 kW for steel tracks and large spirals), with a 200 L oil tank equipped with triple filtration devices (10 μm filtration accuracy), achieving hydraulic oil cleanliness of NAS 8, reducing component wear with an annual system failure rate below 0.5%. The pump station and track motors are connected via high-pressure hoses (30 MPa working pressure) with stainless steel connectors, resisting corrosion in dusty mines and high-salt-spray environments, ensuring hydraulic system reliability in complex conditions.

The spiral scraper system focuses on “impact resistance and low maintenance.” The 6-8 mm thick blades, inlaid with single-tooth HRC62 hardness alloy teeth, are bolt-connected to the blades, allowing individual replacement of worn parts within 2 hours without dismantling the entire spiral shaft. The spiral shaft is made of 45# seamless steel tubing (diameter ≥150 mm), with self-aligning bearings at both ends to compensate for slight vibrations during track movement, preventing material jams. The drive unit uses 22-75 kW high-power motors, precisely matched to capacity gradients (22-37 kW for 100-500 tph, 45-55 kW for 500-1200 tph, 75 kW for 1200-2000 tph), with an IP55 protection rating to withstand rain and dust in open-pit mine operations. The accompanying reducer offers three models: ZQ350 dual output, ZQ400 dual output, and ZLY250 hard-tooth surface dual output, with the hard-tooth surface reducer achieving 97% transmission efficiency and 50% higher load-bearing capacity than standard models, capable of withstanding sudden impacts from large material blocks during track movement, preventing drive interruptions.

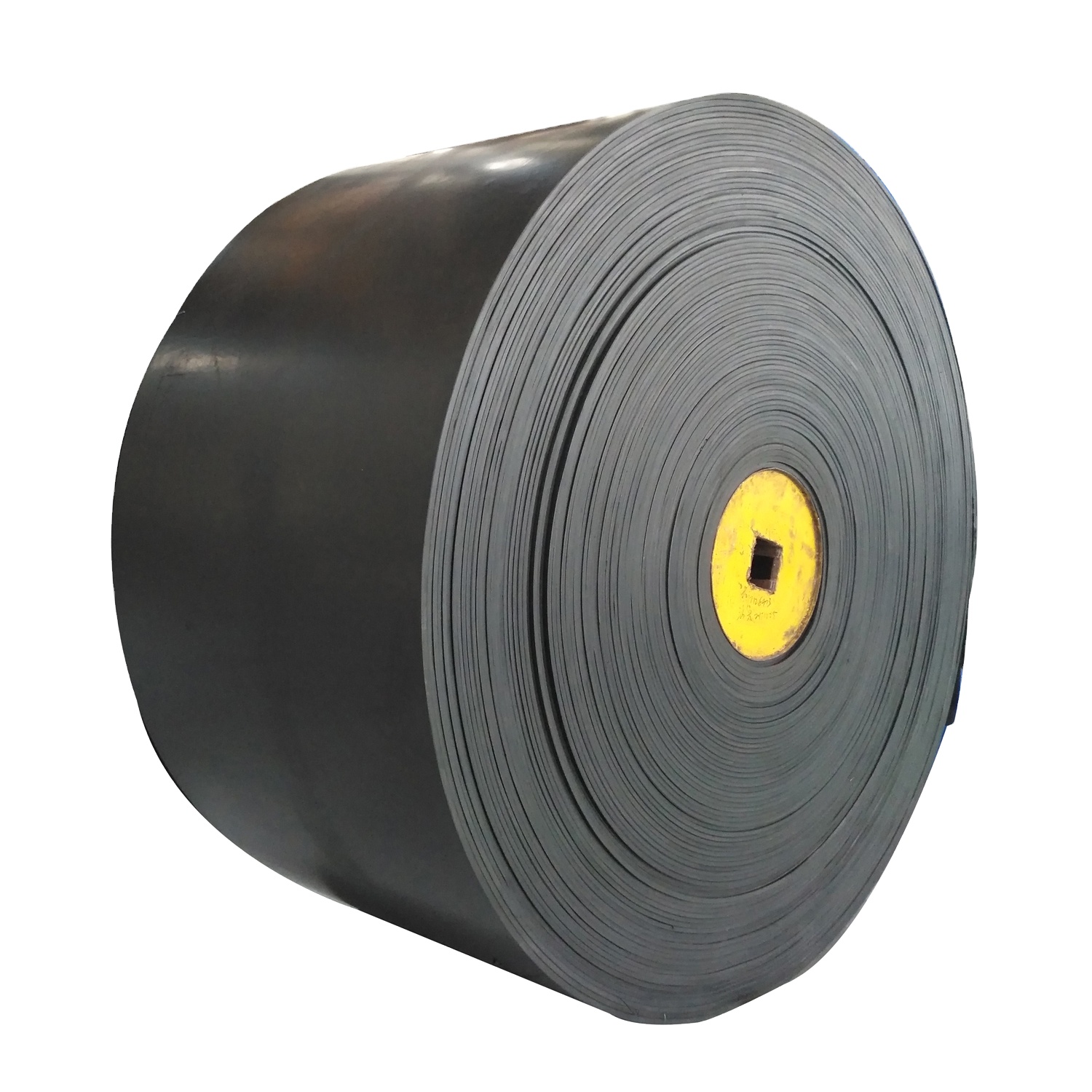

The conveyor belt system, as the core link between “scraping and transfer,” is designed for “anti-slip and leak prevention.” The belt width ranges from 800-1600 mm, selected based on capacity and material block size (800-1000 mm for 100-800 tph, 1200-1600 mm for 800-2000 tph). The conveyor belt is made of nylon-core anti-slip rubber with a longitudinal tensile strength of 1600 N/mm, featuring an 8 mm deep diamond-patterned surface that enhances anti-slip performance by 40%, preventing slippage of wet materials (e.g., wet coal, sticky gravel) during track movement. Both sides are equipped with 350 mm high wear-resistant rubber skirts with embedded steel wire frameworks to reduce material side leakage, meeting the needs of “continuous conveying during movement.” The drive uses a 15-30 kW electric drum, eliminating the need for additional motor and reducer installations, offering a compact structure and easy maintenance. The electric drum has built-in overheat protection (automatic shutdown above 120℃) to prevent burnout during track movement overloads. The 12-15 m long conveyor belt, paired with a 4-meter fixed discharge height, directly connects to downstream equipment, minimizing process losses during mobile operations.

Global Modular Transport and Efficient Installation

Addressing the pain points of global clients, such as “complex terrain project transport difficulties and long installation cycles,” the ZOOMRY Tracked Spiral Scraper Conveyor adopts a “track module prioritized disassembly + high pre-assembly ratio” design, ensuring all-terrain performance while significantly reducing cross-border transport and on-site installation barriers, meeting rapid commissioning needs in different regions.

The modular disassembly design ensures globally compliant transport. The equipment can be disassembled into four standard units: tracked chassis module, spiral scraper module, conveyor belt module, and control module, each sized to fit a 40-foot high-cube container (12.03 m long × 2.35 m wide × 2.69 m high). The tracked chassis module folds track plates hydraulically, reducing height to 2.4 m, with rubber track modules weighing ≤22 tons and steel track modules ≤25 tons; the spiral and conveyor belt modules split into 2-3 segments, each ≤6 m long and ≤10 tons; the control module is integrated into a waterproof enclosure, requiring no special transport permits. Compared to the “special transport + oversized customs clearance” model for traditional tracked equipment, this design reduces cross-border logistics costs by 40%. Core components (e.g., track plates, spiral blades) are factory-packaged with anti-rust and anti-collision materials to prevent damage from jolts during transport, accommodating logistics conditions in regions like Europe, Southeast Asia, and Africa.

The high pre-assembly ratio shortens on-site commissioning time. The equipment is 85% pre-assembled at the factory, including precise track-to-chassis connections, spiral-to-motor tuning, initial hydraulic pipeline connections, and control system parameter calibration, undergoing 80 hours of “complex terrain simulation” full-load testing—covering 12° slopes, alternating soft and hard ground scenarios—to ensure fault-free on-site installation. On-site installation requires only three core steps: first, modular unit assembly, connecting the tracked chassis to the spiral module and the conveyor belt module to the frame with high-strength bolts, completed by two people in 2.5 hours; second, final connection of hydraulic pipelines and electrical plugs using quick leak-free connectors, taking ≤1.5 hours; third, no-load testing, checking track steering, spiral scraping, and conveyor belt synergy, completed by a skilled team in one day for full commissioning. ZOOMRY provides a multi-language technical manual with track operation guidelines, along with 24-hour online technical support via video guidance to assist clients in resolving installation issues, enabling deployment without a professional tracked equipment installation team.

Global Compliance and Quality Verification

As a tracked equipment designed for global markets, the ZOOMRY Tracked Spiral Scraper Conveyor ensures compliant use in various countries and regions through multiple international certifications and comprehensive quality control, with specialized testing for complex terrain scenarios to guarantee long-term reliable operation.

International certifications cover mainstream market entry requirements. The equipment has passed EU CE certification (Machinery Directive 2006/42/EC, Electromagnetic Compatibility Directive 2014/30/EU), completing 13 specialized tests for tracked machinery safety requirements, including chassis load-bearing strength, emergency braking response (≤0.5 seconds), electrical safety protection (IP65), and resistance to strong electromagnetic interference in mines, enabling direct entry into the European Economic Area (EEA) market. It also holds EAC certification from the Russian Customs Union, meeting the operational requirements of “-30℃ low-temperature, snowy mine” environments in CIS countries, with technical documentation provided in Russian, including track low-temperature maintenance guidelines and snowy ground operation protocols for local regulatory reviews. Additionally, the equipment complies with ISO 9001 quality management and ISO 14001 environmental management systems, with a fully traceable production process from track plate material testing (yield strength ≥355 MPa) to spiral blade wear testing, with detailed quality records for each step to ensure consistency in mass production.

ZOOMRY’s in-house quality testing center, equipped with track performance test benches, hydraulic system high-pressure laboratories, and over 60 professional testing devices, conducts rigorous testing on core components: for the track system, rubber tracks undergo 1000 soft ground entrapment simulation tests and 500-hour wear tests with no significant deformation; steel tracks undergo 1000 rocky ground impact tests with track plate wear ≤0.5 mm; for the spiral system, blades and teeth undergo 1000 50 kg hard rock impact tests with no breakage or detachment; the hydraulic system undergoes 72-hour sealing tests (30 MPa working pressure) with no leaks; the control system undergoes 100-hour rain tests (IP65 verification) and 100-meter wireless signal anti-mine electromagnetic interference tests, ensuring normal functionality. Each unit undergoes 16 specialized tests before delivery, including “15° slope track climbing tests,” “100-2000 tph capacity switching tests,” and “-30℃ low-temperature startup tests,” with delivery only upon meeting standards, ensuring reliable operation in global complex terrain scenarios.

Technical Parameters

| Item | Specification Parameters |

|---|---|

| Equipment Type | Hydraulic-Driven Tracked Spiral Scraper Conveyor |

| Capacity Range (tph) | 100-2000 |

| Applicable Material Types | Gravel, coal, ore, aggregates, open-pit mine bulk materials, etc. |

| Spiral Outer Diameter (mm) | 500-800 |

| Spiral Scraping Width (m) | 2-3.2 |

| Material Pickup Width (m) | 2.4-3.6 |

| Blade Configuration | 6-8 mm blades + inlaid alloy teeth |

| Motor Power (kW) | 22-75 (spiral drive) |

| Reducer Model | ZQ350 dual output / ZQ400 dual output / ZLY250 hard-tooth surface dual output |

| Conveyor Belt Width (mm) | 800-1600 |

| Conveyor Belt Length (m) | 12-15 |

| Conveyor Belt Power (kW) | 15-30 (electric drum) |

| Conveyor Belt Material | Nylon-core anti-slip rubber belt |

| Discharge Height (m) | 4 |

| Hydraulic Pump Station Motor Power (kW) | 11-18.5 (track drive) |

| Tracked Chassis | Rubber tracks (4009068, effective length 2.9 m, ground pressure 0.07 MPa); Steel tracks (40013554, effective length 3.6 m, carburized and quenched surface), chassis outer width 2.3 m (supports widening) |

| Control System | Stainless steel rainproof control cabinet (IP65), 100 m wireless remote + local control |

| Motor Protection Rating | IP55 (spiral/pump station motor), IP54 (electric drum) |

| Applicable Ambient Temperature (℃) | -30\~60 (resistant to extreme climates) |

| Optional Configurations | Spiral blade wear-resistant coating, conveyor belt Rain Cover, material level sensor, track widening kit, low-temperature hydraulic oil heating system |

Why Choose ZOOMRY

Client Value

Choosing the ZOOMRY Tracked Spiral Scraper Conveyor provides global clients with significant value in all-scenario adaptability, efficiency improvement, and cost optimization. In terms of all-scenario adaptability, the 400 mm dual-configuration tracks cover complex terrains like soft and hard ground, eliminating site leveling costs and reducing preparation expenses by 60% compared to traditional wheeled scraper conveyors. The wide operational range of track-based mobile operations allows a single unit to replace 2-3 fixed scraper conveyors, lowering initial equipment investment.

In terms of efficiency improvement, the “track movement + spiral scraping” synergistic design increases operational efficiency by 35% compared to traditional “fixed scraper conveyor + trailer repositioning” methods. The 100-meter wireless remote control reduces manual intervention, with a single unit replacing multiple operators, lowering labor costs. The 4-meter discharge height precisely matches downstream equipment, avoiding secondary transfer losses and extending annual effective operational time.

In terms of cost optimization, high-wear-resistant components (steel tracks, alloy teeth) extend replacement cycles, reducing maintenance costs by 40% compared to ordinary scraper conveyors. The equipment’s low failure rate (annual failure rate <0.7%) minimizes downtime losses, enabling over 8,000 hours of effective annual operation in open-pit mine scenarios, further controlling comprehensive operational costs.

Service Support

ZOOMRY has established a comprehensive service system of “technical support + spare parts assurance + specialized training” tailored to global client needs, ensuring long-term stable operation of the tracked spiral scraper conveyor. For technical support, multi-language technical documentation is provided (including track operation manuals, complex terrain maintenance guides, and troubleshooting manuals), covering track steering tuning, low-temperature hydraulic system maintenance, and spiral material jam emergency handling, accompanied by clear diagrams. 24-hour online technical support (email: oversea@zoomry.cn; phone: +86-13164016717) offers engineer responses within 4 hours, with assigned personnel having over 8 years of tracked equipment service experience, familiar with equipment pain points in complex scenarios like mines and open stockyards.

For spare parts assurance, ZOOMRY leverages an efficient global supply chain collaboration system, pre-stocking common spare parts like track plates, alloy teeth, and hydraulic filters. Upon client request, parts are shipped quickly via international logistics, with delivery cycles optimized based on the client’s region. For key clients, a “spare parts pre-planning service” is offered, developing procurement and storage plans based on track wear cycles and operational intensity, using bulk shipments or phased restocking to avoid downtime.

For specialized training, ZOOMRY provides “track operation + complex terrain handling” training for client teams in different regions, covering track climbing techniques, soft ground anti-entrapment operations, and spiral-track synergy parameter optimization. Through a combination of theoretical and practical training, clients’ teams master core equipment operation points, meeting complex terrain operational needs.

ZOOMRY

ZOOMRY