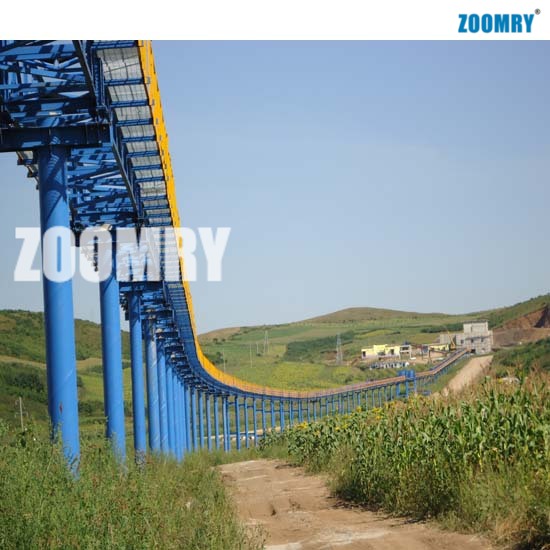

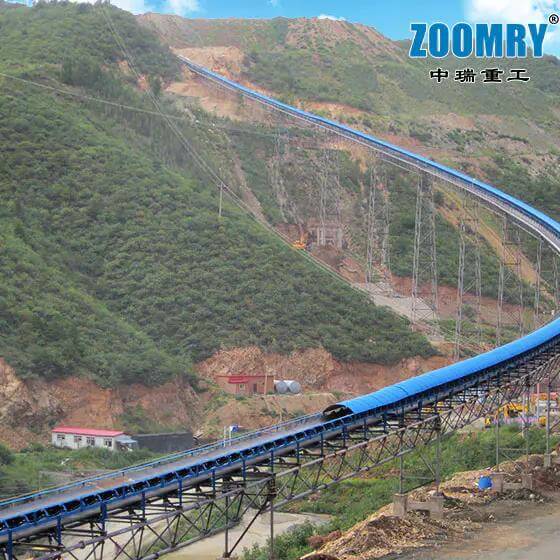

As a belt conveyor manufacturer with more than 20 years of production experience. Zoomry is a factory integrating design, R&D, and manufacture. Our company has professional after-sales service team, which can solve customer's problem in 24 hours. Our mission is to create value for customers and make transportation more environmentally friendly and efficient! Our vision is to become the leader in the global bulk material handling industry!

ZOOMRY

ZOOMRY