Designed specifically for heavy bulk material scenarios such as iron ore, granite, coal, and cement clinker, the product integrates "high load-bearing capacity, strong adaptability, intelligent control, and low wear". It features an extra-large hopper capacity of 12-24m³, an extreme handling capacity of 3000TPH, and an IP65 protection rating. Compatible with both wheel-type and tracked chassis options, it is equipped with a heavy-duty belt or chain plate feeding system, which can directly connect to feeding equipment such as loaders, excavators, and grab cranes to realize non-secondary handling and transportation of heavy bulk materials. Widely used in global mining, port loading and unloading, building materials production, energy and chemical industries, etc.

Core Technical Parameters

| Technical Indicators | Specific Parameters |

|---|---|

| Hopper Capacity | 12-24 m³ (up to 28m³ in stacking state) |

| Maximum Handling Capacity | Up to 3000 TPH (tons per hour) |

| Adaptable Feeding Particle Size | ≤250 mm (millimeters) |

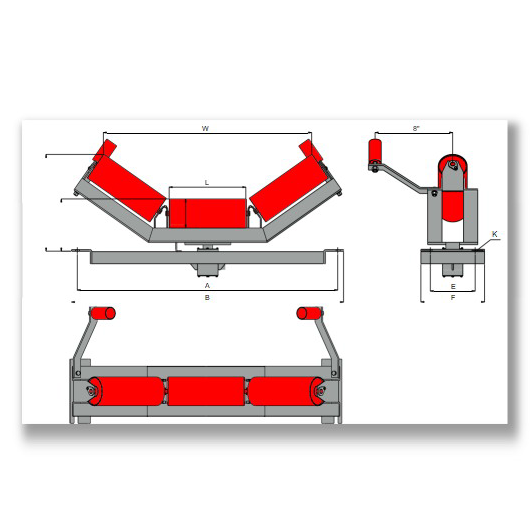

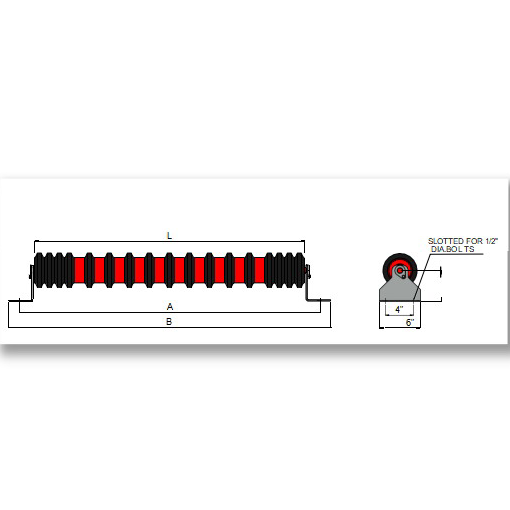

| Feeding System Specifications | Heavy-duty belt/chain plate dual options; belt width 1400mm (56"), chain plate with 8mm+2mm wear-resistant layer design |

| Inclined Arm Length | 15-24 m, customizable according to on-site requirements |

| Maximum Discharge Height | 5.5-8.2 m (intelligently adapted to inclined arm length) |

| Drive Mode | Dual-motor drive (electric/hydraulic optional, supporting variable frequency speed regulation) |

| Chassis Type | Wheel-type/tracked dual options; tracked type equipped with hydraulic crawler tracks |

| Applicable Materials | Iron ore, granite, coal, cement clinker, ore, coke and other heavy bulk materials |

| Protection Rating | IP65 (NEMA-4 rating), suitable for harsh working conditions |

| Transportation Method | Supports RORO (Roll-on/Roll-off) transportation and 40ft high cube container transportation |

Core Product Advantages

High Processing Efficiency

- Extra-large hopper capacity of 12-24m³, combined with a 70° conical hopper design and expandable hopper side plates (300mm-900mm), can withstand full-load feeding from loaders and excavators at one time, avoiding frequent feeding waits and reducing equipment idle time;

- Extreme handling capacity of 3000TPH, equivalent to 3300 US tons of heavy bulk materials transported per hour, far exceeding the industry average. Particularly suitable for large-scale processing scenarios such as large mines and ports, a single device can meet the feeding needs of the entire production line;

- Feeding system optimized for different material characteristics: The heavy-duty belt option adopts EP800 5-layer cord + 8mm+2mm wear-resistant rubber layer design, which is tear-resistant and wear-resistant, suitable for medium-hard materials such as coal and cement clinker; The chain plate option is made of hardened steel, matched with ceramic lagged drive rollers, which can easily handle high-wear materials such as iron ore and granite. The maximum feeding particle size is 250mm, no additional crushing pretreatment is required.

Flexible Adaptability

- Dual-chassis design: Wheel-type chassis is suitable for flat sites (such as factory workshops and ports), with convenient movement and efficient transfer; Tracked chassis is equipped with hydraulic adjustable outriggers and anti-skid crawler tracks, featuring low ground pressure, which can operate stably on rough terrain such as mines and construction sites without additional site leveling, significantly reducing construction costs;

- Flexible switching of drive modes: The electric drive option is energy-saving and efficient, suitable for fixed scenarios with stable power supply, featuring low operating noise and meeting environmental protection standards; The hydraulic drive option has strong power and fast response speed, suitable for mobile scenarios without stable power supply (such as mine sites). The dual-motor drive design ensures power redundancy and avoids shutdown caused by single-point failure;

- Global working condition adaptability: IP65 (NEMA-4 rating) protection level, the electrical system and hydraulic system of the equipment adopt fully sealed design, which can resist harsh environments such as dust, humidity, high and low temperatures. Whether it is high temperature and humidity in tropical mines or low temperature and cold in temperate ports, it can operate stably; At the same time, it is compatible with engine configurations meeting EU Stage V/Tier 4 Final and EU Stage IIIA/Tier 3 emission standards, satisfying environmental protection requirements in different regions around the world.

Safety and Durability

- Upgraded wear-resistant structure: The hopper lining is made of 6mm hardened steel or 15mm ULF super wear-resistant material, effectively resisting impact and wear of heavy bulk materials. The hopper is integrated with a bolt-fixed anti-falling system to avoid material splashing and equipment damage; The feeder frame is welded with high-strength steel structure, optimized through finite element analysis, with strong deformation resistance and a service life of more than 10 years;

- Intelligent safety protection: The equipment is equipped with a NEMA-4 rated control panel, integrating emergency stop button, operation status monitoring, and fault alarm functions, with intuitive and convenient operation; The feeder body is equipped with a pull-rope emergency stop device, arranged along the entire length of the body, enabling quick shutdown at any position; The interlocking function with subsequent equipment ensures the coordinated safety of the entire production line, avoiding potential safety hazards such as material accumulation and equipment collision;

- Low-maintenance design: The centralized lubrication system aggregates all lubrication points to easily accessible positions, reducing the workload of maintenance personnel; Wear parts (such as belts, chain plates, and idlers) adopt standardized design, with strong versatility and convenient replacement; The hydraulic system is equipped with an efficient cooler and filtering device, extending the service life of hydraulic oil, reducing the failure probability of hydraulic components, shortening the annual maintenance time by more than 30%, and significantly reducing the total life cycle cost.

Intelligent Production

- Variable frequency speed regulation system: The feeding speed can be accurately adjusted through the VSD (Variable Speed Drive) frequency converter, ranging from 0-100%. It can real-time match the feeding volume according to the processing capacity of subsequent equipment, avoiding material accumulation or insufficient supply, and ensuring the balanced operation of the entire production line;

- Human-machine interaction experience: Equipped with a Universal HMI (Human-Machine Interface) and fault display system, it real-time monitors equipment operating parameters (such as feeding volume, motor temperature, and hydraulic pressure). Fault information is automatically alarmed and recorded, facilitating maintenance personnel to quickly troubleshoot; Supports wireless remote control operation, allowing operators to remotely control equipment movement, feeding speed adjustment, start and stop functions in a safe area, improving operational convenience and safety;

- Collaborative linkage capability: The equipment reserves standard communication interfaces, which can be connected to the customer's existing PLC control system and MES production management system, realizing automatic scheduling and data management of the feeding process, and providing core support for the construction of intelligent factories.

Applicable Scenarios

Mining Industry

- Application Scenarios: Feeding and transferring of ore after mining in open-pit mines and underground mines, such as iron ore, copper ore, granite mines, etc.;

- Application Solutions: Directly connect to excavators and loaders for feeding, transporting ore directly from the mining site to crushers and belt conveyors, eliminating secondary handling, improving mining efficiency, and reducing labor and equipment costs; The tracked chassis is suitable for rough terrain in mines, with a wear-resistant feeding system that resists high-intensity wear, meeting the 24/7 continuous operation requirements.

Ports and Terminals

- Application Scenarios: Loading and unloading of bulk cargo ships, stockpiling and reclaiming at ports, such as terminal transfer of bulk materials such as coal, coke, and ore;

- Application Solutions: The high handling capacity of 3000TPH meets the large-scale operation needs of ports. The wheel-type chassis facilitates flexible movement and efficient transfer in port yards; The inclined arm length of 15-24m can adapt to different tonnages of ships and stockpiling heights; Supports RORO transportation and 40ft high cube container transportation, enabling quick arrival and installation of equipment at ports and shortening the project commissioning cycle.

Building Materials and Energy Industry

- Application Scenarios: Feeding of cement clinker production lines, feeding of coal conveying systems in coal-fired power plants, aggregate transportation in building materials factories, etc.;

- Application Solutions: Adapts to different characteristics of materials such as cement clinker, coal, and aggregates. Precise feeding ensures stable production processes. The electric drive option meets environmental protection requirements. The low-maintenance design reduces production line downtime and ensures continuous production.

Recycling and Infrastructure Fields

- Application Scenarios: Construction waste recycling and treatment, aggregate transportation in large-scale infrastructure projects (such as hydropower stations and highways);

- Application Solutions: The chain plate feeding system can handle hard blocks and impurities in construction waste. The tracked chassis adapts to complex terrain at infrastructure sites. The modular design facilitates transfer and transportation, meeting the feeding needs of different project stages.

Choose ZOOMRY

Customized Solutions

- Hopper Customization: According to the customer's feeding equipment (loader and excavator models) and material characteristics, customize the hopper capacity (within 12-24m³), hopper angle, and hopper lining material. Optional vibrating or inclined hopper grids to prevent blockage by large materials;

- Feeding System Customization: According to material hardness and wear resistance, choose heavy-duty belt or chain plate feeding system. The belt material can be upgraded (such as Chevron pattern belt) or the thickness of the chain plate wear-resistant layer can be increased to improve equipment adaptability;

- Chassis and Size Customization: According to site conditions and mobility requirements, choose wheel-type or tracked chassis. Customize the inclined arm length (15-24m) and discharge height (5.5-8.2m) to adapt to the docking height of different subsequent equipment;

- Power and Control Customization: According to the customer's energy conditions, choose electric, hydraulic or hybrid drive. The intelligent control system can be upgraded to add remote monitoring, data collection and analysis functions, realizing predictive maintenance of equipment.

Service Guarantee

- Global Service Network: Provide 24/7 technical support, quickly respond to customer needs, and ensure timely resolution of equipment failures;

- Professional Installation and Commissioning: Dispatch experienced technical engineers to provide on-site installation guidance and commissioning services, ensuring quick commissioning of equipment and reaching the designed handling capacity;

- Training and Maintenance: Provide comprehensive training for customer operators and maintenance personnel, including equipment operation, daily maintenance, and fault troubleshooting, and issue detailed operation manuals and maintenance guides; Conduct regular customer visits, provide preventive maintenance suggestions, and extend equipment service life;

- Quality Commitment: Core components of the equipment (such as motors, hydraulic systems, and drive rollers) adopt internationally renowned brands (such as CAT, Deutz, NEMA-certified components). The product has passed ISO9001 quality management system certification and CE certification, providing a 1-year warranty period. During the warranty period, faulty components will be replaced free of charge (excluding human damage).

Brand Strength

ZOOMRY has been focusing on the R&D, production and sales of bulk material conveying equipment for many years. Its product range covers core equipment such as belt conveyors, telescopic stackers, Mobile Ship Loaders, truck unloaders, and hopper feeders, as well as key components such as idlers, rollers, and cleaning scrapers, forming a complete product matrix. With technical strength benchmarking international first-tier brands and cost advantages of local production, the products have been exported to more than 50 countries and regions worldwide, serving well-known enterprises in industries such as mining, ports, building materials, and energy, and winning a global reputation for "efficiency, reliability, and professionalism".

In the field of heavy bulk material conveying, ZOOMRY has always adhered to the development concept of "driven by technological innovation", continuously invested in R&D resources, optimized product performance, and launched customized solutions for pain points in different industries. As one of the core products, the hopper feeder not only reflects ZOOMRY's technical accumulation and manufacturing strength, but also demonstrates the global competitiveness of China's equipment manufacturing industry, creating greater value for customers around the world!

ZOOMRY

ZOOMRY