Mengxi Group Cement Plant in Inner Mongolia focuses on limestone deep processing business, with limestone as its core raw material (particle size 5-30mm, moisture content 2%-5%, dust prone to diffusion in dry environments, and easy to agglomerate due to electrostatic adsorption at low temperatures). Previously, the transportation of limestone from the mine crushing area to the plant's raw material warehouse relied entirely on heavy trucks. Under the special environment of Inner Mongolia, the transportation drawbacks have become increasingly fatal: the 4,650-meter transportation distance requires bypassing 6 natural turns in the hills, a single trip takes more than 1 hour, and the average daily transportation efficiency is less than 800 tons, far below the production capacity requirement of 1,200 tons per hour; the low temperature of -25℃ in winter causes frequent freezing cracks in the truck's hydraulic system, while the high temperature of 38℃ in summer leads to a sharp increase in tire blowout rate, resulting in an annual downtime of over 80 hours due to vehicle failures; the dust emission from open transportation reaches 23mg/m³, far exceeding the national standard limit, and the local environmental protection department has issued rectification notices many times; due to the lack of buffer protection during limestone loading and unloading, the high hardness of limestone causes a material collision loss rate of 4.8%, with an annual loss of over 550,000 tons, keeping raw material costs high.

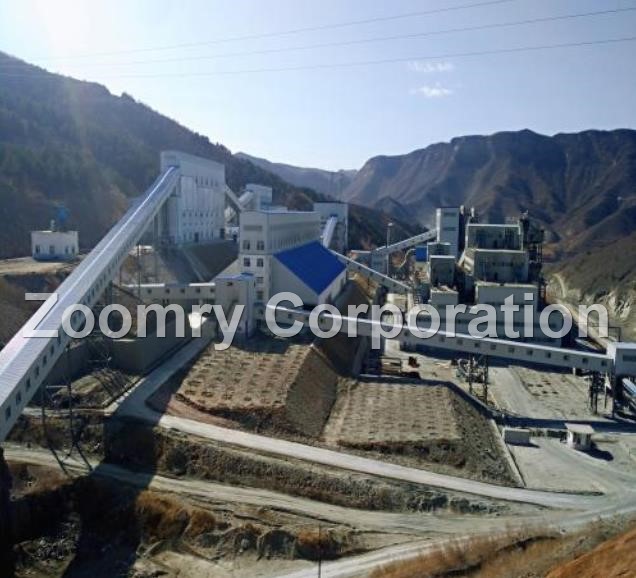

To completely solve these problems, the plant decided to customize an exclusive conveying system, requiring the plan to overcome the three major challenges of "adaptation to extreme temperature differences, stable conveying with multiple curves, and dry dust control", and to provide full-process new construction services (no reuse of old equipment). Based on on-site 3D topographic surveys and meteorological data, ZOOMRY has targetedly designed a customized plan centered on "long-distance curved belt conveyors + cold-resistant and dust-proof supporting equipment", with all equipment exclusively developed for the working conditions in Inner Mongolia.

Project Requirements and Objectives

Core Requirements

- Terrain adaptation: The 4,650-meter line needs to cover 6 horizontal curves (radius 1,000-1,500 meters), achieve a lifting height of 25 meters, have a handling capacity of ≥ 1,200 tons per hour, and adopt head + tail dual drives to balance the tension in hilly terrain;

- Environmental adaptation: The equipment needs to operate stably under a temperature difference of -25℃~38℃, with the Conveyor Belt not becoming brittle at low temperatures and not aging at high temperatures, and the frame resisting wind and sand erosion;

- Material adaptation: The dust emission of dry limestone needs to be ≤ 8mg/m³, while avoiding material agglomeration caused by low-temperature static electricity;

- Full-process planning: It is necessary to cover all links from line planning, equipment customization to operation and maintenance training, and provide localized spare parts response in Inner Mongolia (≤ 7 days).

Core Objectives

- Efficient conveying: The 4,650-meter full journey without transshipment, with a stable handling capacity of 1,200 tons per hour, completely replacing truck transportation;

- Low loss and environmental protection: The equipment failure rate under extreme temperature differences is ≤ 0.8%, dust emission is ≤ 8mg/m³, and limestone loss rate is ≤ 1%;

- Stable quality: The service life of core components is ≥ 50,000 hours, the operation and maintenance team can operate independently, and the spare parts response time is ≤ 7 days.

Limestone Conveying Project Plan for Cement Plant

Core Equipment

Targeting the three core pain points in Inner Mongolia, the conveyor has made breakthrough designs from structure to material:

- Dual adaptation to multiple curves and temperature differences: The 6 curved sections adopt the "gradual tension compensation technology", and each curve radius (1,000-1,500 meters) corresponds to an exclusive idler group angle (15°-20° adjustable), matched with ZOOMRY's independently developed "friction self-aligning idlers" (diameter 133mm, suitable for 1,200mm belt width). The idler bearings are filled with low-temperature grease (non-solidifying at -30℃), with radial runout ≤ 0.4mm, no jamming in the 72-hour sand and dust test, and can automatically correct belt deviation to avoid material scattering in curved sections; the 25-meter lifting section adopts a "5.5% gentle slope", matched with the ST2500 cold-resistant steel cord conveyor belt (customized model). The surface of this conveyor belt is added with antistatic agent (to prevent low-temperature electrostatic agglomeration), with no cracks after 100 bends at -25℃, and a tensile strength retention rate of ≥ 95% after the 38℃ high-temperature aging test. The 120mm overlapping sealing structure can also block dust diffusion.

- Dual-drive power and temperature control system: The 630kW head + 570kW tail variable-frequency motors (total power 1,200kW) adopt the "low-temperature preheating module". Before starting in winter, the motor temperature can be raised to above -5℃ through electric heating to avoid coil freezing cracks; the drive drum is made of 40Cr forged material (diameter 500mm), with the diamond-shaped rubber coating on the surface added with cold-resistant agent (non-hardening at -25℃), a friction coefficient of ≥ 0.45, and no internal defects detected by ultrasonic flaw detection, which can cope with the heavy-load conveying of limestone; the hydraulic tensioning device is equipped with an "intelligent dual oil temperature control system", which automatically heats the oil at low temperatures (raising the temperature to 10℃) and starts air-cooled heat dissipation at high temperatures (temperature control ≤ 50℃) to ensure stable tension.

- Wind and sand protection and dust prevention design: The frame adopts hot-dip galvanizing + polytetrafluoroethylene coating (wind and sand erosion resistance increased by 70%), an "arc-shaped dust cover + side wind baffle" is installed above the conveyor belt, antistatic cotton is attached to the inner side of the dust cover (to avoid dust adsorption), and the side wind baffle can adjust the angle (0-30°) according to the monsoon direction in Inner Mongolia to reduce the impact of wind and sand on the belt.

Supporting Equipment

- ZRLS-TU1400 Wheel-type truck unloader: The receiving area equipment is specially designed for the low temperature in Inner Mongolia. The oil cylinders of the 2 hydraulic ramps are added with low-temperature antifreeze oil (meets the fluidity standard at -30℃), and anti-skid steel plates are laid on the surface of the ramps (no slipping when icy in winter); the unloading end is equipped with a "two-stage dust curtain" (inner rubber curtain + outer antistatic nylon curtain), increasing the dust interception rate to 98%; the vibrator of the vibrating feeding device adopts a sealed design (to prevent sand and dust from entering) and can adjust the frequency (50-100Hz) in real time according to the conveyor load to ensure the feeding stability of 1,200 tons per hour.

- ZR-D120 hopper feeder: Installed between the unloader and the conveyor, the hopper has a 10cbm conical structure (to avoid limestone bridging and agglomeration at low temperatures), and the inner wall is paved with 12mm thick wear-resistant ceramic lining (added with antistatic coating); the top dust cover integrates a "pulse dust removal port" (can be externally connected to the plant's dust removal system), and a "low-temperature heating ring" is installed at the bottom discharge port (temperature control 5-10℃ in winter to prevent material agglomeration and blockage); the 18.5kW variable-frequency motor is equipped with "low-temperature start protection", and the starting current is controlled within 1.2 times the rated value to avoid coil burnout in winter.

Core Components

- Idlers and Drums: Mute idlers are used in the straight sections. The bearings are customized cold-resistant models from Harbin Bearings (normal rotation at -30℃), with rotational resistance ≤ 2N (better than the national standard of 3N) and operating noise ≤ 45dB; the surface of the bend drum is sprayed with a "tungsten carbide + cold-resistant resin composite coating" (thickness 8mm), increasing wear resistance by 80%, with an ellipticity deviation of < 1.5mm at -25℃, ensuring stable operation of the belt.

- Cleaning and Safety Components: The cleaning scraper has a composite structure of "cold-resistant PU + metal frame" (non-hardening at -25℃), with a fitness with the conveyor belt of ≥ 98%, which can remove residual electrostatically adsorbed dust; the safety system adds a "low-temperature tension monitoring module", which automatically detects the belt tension every 30 minutes in winter (to avoid excessive tension caused by low-temperature shrinkage) and is also equipped with "emergency windproof braking" (automatically locks the belt when the wind speed exceeds 15m/s), meeting the safety needs of windy and sandy weather in Inner Mongolia.

Project Implementation

Preliminary Survey

A 6-person technical team from ZOOMRY completed the special survey in 12 days: using UAVs to map the 3D terrain of the 4,650-meter line, marking the center coordinates and slope changes of the 6 curves, and avoiding the soft sandy soil foundation in the hilly area; collecting meteorological data of the past 5 years (days with extreme temperature differences, frequency of wind and sand, rainfall distribution) to determine the equipment insulation and wind-sand protection design parameters; conducting laboratory tests on the fluidity and static value of limestone at -25℃ and 38℃ to provide data support for the antistatic coating of the conveyor belt and the hopper heating ring.

Customized Production

All equipment is exclusively produced at ZOOMRY's Hebei Factory and must pass the Inner Mongolia working condition simulation test: the cold-resistant conveyor belt needs to be placed in a -25℃ low-temperature box for 24 hours and then bent without cracks; the idlers need to pass a 1,000-hour "low-temperature - high-temperature - sand and dust" cycle test (-25℃ operation for 2 hours → 38℃ operation for 2 hours → sand and dust injection for 1 hour); the drive motor needs to complete 50 low-temperature preheating start tests to ensure winter reliability. The cement plant sent representatives for on-site acceptance, and all parameters met the customized requirements.

On-site Installation

A 10-person installation team adopted the "modular splicing + wind and sand shelter" construction method: dividing the 4,650-meter conveyor into 23 sections (each section 200-210 meters), with only bolt connection required on-site after factory pre-assembly, and a mobile wind and sand shelter built at the same time (to resist the monsoon in Inner Mongolia); during winter installation, the hydraulic pipelines were protected with "electric heat tracing + thermal insulation cotton" dual protection to avoid oil freezing; during the commissioning phase, a 72-hour "temperature difference simulation test run" was conducted (35℃ during the day and -20℃ at night), and the PLC program was optimized to stabilize the conveyor at a handling capacity of 1,250 tons per hour.

Operation and Maintenance Training

15-day training was provided for 8 operation and maintenance personnel of the cement plant: focusing on explaining the preheating steps of the hydraulic system in winter (motor heating → oil circulation → tension calibration), the cleaning frequency of the dust cover in summer (cleaning sand and dust once every 3 days), and the wear judgment of idlers in curved sections (listening for abnormal noise + measuring runout); graphical operation manuals were provided, and all cases in the manuals were compiled based on the working conditions in Inner Mongolia; an Inner Mongolia regional spare parts channel was established, and common spare parts (such as cold-resistant idlers and dust curtains) could be delivered within 7 days through nearby service outlets.

Project Results

After the project was put into operation, the conveying line of the building materials plant achieved a breakthrough from 0 to 1, and all exclusive designs for Inner Mongolia were accurately implemented:

- Efficiency and Cost Optimization: The 4,650-meter full journey without transshipment, with a stable handling capacity of 1,250 tons per hour, far exceeding the production capacity requirement; the conveying cycle was shortened from 1 hour to 1.8 hours, reducing downtime by 60 hours per year; the limestone loss rate was reduced from 4.8% to 0.7%, reducing annual loss by 528,000 tons and significantly lowering raw material costs.

- Extreme Environment Adaptation: At -25℃ in winter, the conveyor belt had no cracks, the hydraulic system had no freezing cracks, and the equipment failure rate was reduced from 30% to 2%; at 38℃ in summer, the motor temperature rise was controlled within 45℃, with no overload problem; the dust emission was stably maintained at 7.2mg/m³, and the environmental rectification problem was completely solved.

- Operation and Maintenance Guarantee: The core components (idlers, conveyor belts, drive motors) had been in operation for more than 30,000 hours without replacement, the average annual maintenance frequency was reduced from 12 times to 3 times, and maintenance costs were reduced by 45%; the spare parts response in the Inner Mongolia region was efficient. Previously, a single idler failure was replaced within 5 days without affecting production.

The person in charge of the project at the building materials plant said: "What is most surprising is that ZOOMRY has taken into account the temperature differences and wind and sand in Inner Mongolia - we no longer have to worry about belt freezing cracks in winter, the motor does not overheat in summer, and the dust control is particularly good. Previously, we worried about failures every day with truck transportation, but now this customized conveying line requires no worry at all. We will definitely choose ZOOMRY again for future production expansion."

Core Advantages of ZOOMRY

- In-depth working condition customization capability: Targeting the extreme temperature differences and wind and sand in Inner Mongolia, it has innovatively developed exclusive technologies such as "cold-resistant conveyor belts, low-temperature preheating motors, and wind-sand-proof dust covers", completed the full set of plan design in 2.5 months, and all equipment details correspond to specific pain points rather than general templates;

- Localized implementation capability: From survey (focusing on Inner Mongolia meteorological data), production (simulating Inner Mongolia working condition tests) to installation (wind-sand-proof and low-temperature construction), all links are in line with the local environment, avoiding the "inadaptability of general equipment";

- Localized operation and maintenance guarantee: It has established a regional spare parts channel based on domestic service outlets, responding to Inner Mongolia's needs within 7 days, and providing targeted operation and maintenance training at the same time to ensure that customers can independently cope with local special working conditions.

ZOOMRY

ZOOMRY