Khabarovsk Krai in Russia is located in the permafrost region of the Far East, with long winters and extreme low temperatures (a minimum of -35°C). Nevertheless, it holds over 3 billion tons of high-quality thermal coal reserves and maintains a stable annual production capacity of more than 20 million tons, serving as a core hub for Russia's coal exports to the Asia-Pacific region (China, South Korea, Japan). However, a large coal mine in this region has long relied on outdated fixed stacker-reclaimer equipment, leading to several problems:

Low-temperature environment-induced equipment failure—traditional hydraulic systems frequently solidify at temperatures below -25°C, the failure rate of electrical components is as high as 8 times per month, and the average daily downtime for maintenance in winter reaches 4 hours; mismatch between production capacity and efficiency—the daily operating capacity of a single piece of equipment is less than 300 tons, and the average daily handling capacity of the entire system is only 900 tons, far below the coal mine's daily mining output demand of 1,500 tons. A large amount of coal accumulates at the wellhead, facing the risk of freeze-thaw deterioration.

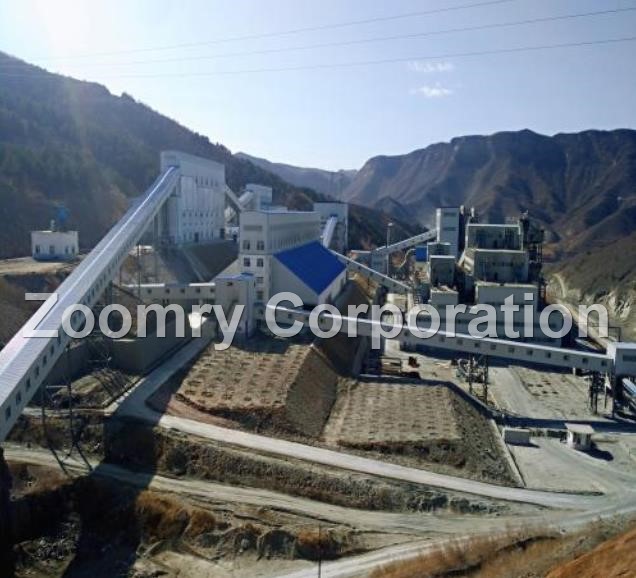

In response, a Russian coal transportation group launched the "Coal Conveying Upgrade Project in Permafrost Regions," planning to phase out 8 sets of outdated equipment and purchase high-efficiency stacker-reclaimer equipment adapted to low-temperature environments. Meanwhile, the equipment must meet the latest dust emission standard (≤10mg/m³) set by the Russian Federal Service for Supervision of Natural Resources (Rosprirodnadzor). After comparing international brands from Ireland, Sweden and other countries, the group ultimately chose Zoomry Heavy Industry (Zoomry)—the core reasons are that Zoomry not only holds the mandatory EAC Certification for the Russian market, but also provides exclusive customized solutions for -35°C environments. Additionally, the service life of its independently produced core components such as idler rollers and drums exceeds 50,000 hours, far surpassing the industry average of 30,000 hours of competitors.

Project Requirements

Combining the operational characteristics of permafrost regions and production capacity goals, the Russian coal transportation group put forward clear and stringent requirements for the equipment, ensuring it "can withstand low temperatures, improve efficiency, meet environmental standards, and ensure service support":

- Capacity and Specification Adaptation: 8 sets of telescopic stackers are required, with a fixed section of 25 meters + a telescopic section of 15 meters, and a maximum operating radius of 40 meters to meet the needs of "large-reserve stockpiling + multi-point reclaiming." The daily capacity of a single piece of equipment must exceed 500 tons, and the average daily handling capacity of the entire system must reach 1,500 tons;

- Extreme Low-Temperature Resistance: The equipment must operate stably in the full temperature range of -35°C to 40°C. Hydraulic oil, seals, and tires must have anti-freezing performance to avoid issues such as low-temperature brittleness and lubricating oil solidification. The failure rate during continuous operation in winter must be ≤1%;

- Environmental Protection and Safety Compliance: Equipped with high-efficiency dust control devices to ensure dust concentration ≤10mg/m³ during coal stacking and reclaiming. At the same time, it must integrate safety functions such as emergency shutdown, wire rope breakage protection, and belt deviation early warning, complying with Chapter 12 "Heavy Machinery Safety Standards" of Russia's Industrial Equipment Safety Regulations;

- Localized Services: Since the project is located in a remote mining area of Khabarovsk Krai, Zoomry is required to provide on-site installation guidance and Russian-language operator training. A spare parts warehouse must be established in Vladivostok to ensure spare parts are delivered within 48 hours after a fault occurs and operations are resumed within 72 hours.

Zoomry's Solution

To meet the customer's needs, Zoomry established a special team consisting of experts in low-temperature materials, hydraulic systems, and electrical control. Based on the ZR-SF Radial Telescopic Stacker, the team customized the equipment for low-temperature scenarios from three aspects: equipment structure, core components, and intelligent control, forming a complete solution.

Key Equipment Features

- Telescopic and Operating Range: Fixed section of 25 meters + telescopic section of 15 meters, with a maximum operating radius of 40 meters. The stockpiling capacity is 80% higher than the customer's original equipment, covering 3 coal stockpiling areas simultaneously without frequent equipment movement to adjust positions;

- Handling Efficiency: The rated handling capacity of a single unit is 550 TPH (tons per hour), and the peak capacity can reach 600 TPH. Calculated based on a daily operating duration of 10 hours, the daily capacity reaches 5,500 tons (44,000 tons for 8 units), fully covering the coal mine's daily output demand of 1,500 tons;

- Transportation and Assembly: The equipment can be disassembled into 6 modules of 40”HQ containers, with an on-site assembly cycle of only 20 days, significantly shortening the downtime of mining operations.

Targeted System Modifications

To cope with the extreme low temperature of -35°C, the special team modified four key systems to ensure reliable winter operation of the equipment:

- Anti-Freezing Modification of Hydraulic System: Special anti-freezing hydraulic oil for -40°C (viscosity index ≥140) is adopted. A 2kW electric heating device is installed in the hydraulic oil tank, which automatically starts when the oil temperature is below -10°C to ensure the viscosity of the hydraulic oil is maintained within 200 cSt and prevent system jamming;

- Low-Temperature Protection of Electrical Components: Siemens S7-1200 series low-temperature PLC controllers (operating temperature: -40°C to 70°C) are selected. Sensors for temperature, pressure, etc., adopt IP67 protection level and have built-in heating modules, enabling startup within 3 seconds in a -35°C environment without startup delay;

- Weather-Resistant Upgrade of Travel System: 8 super wear-resistant and anti-freezing solid tires of model 23.5-25 are used. The rubber formula is added with 30% butyl rubber anti-freezing agent, maintaining a Shore hardness of 65±5HA at -35°C to avoid hardening and cracking. Meanwhile, a crawler-type auxiliary travel device is equipped to cope with soft roads in permafrost regions;

- Low-Temperature Strengthening of Structural Materials: The equipment frame is made of Q355ND low-temperature tough steel. After welding, low-temperature aging treatment at -40°C is carried out, with an impact toughness of ≥34J to prevent brittle fracture of structural parts at low temperatures. Key connection parts use 316 stainless steel bolts to avoid electrochemical corrosion in permafrost regions.

High-Performance Core Components

As an enterprise with a complete industrial chain of bulk material conveying equipment, Zoomry independently produces core components such as idler rollers and drums, with performance indicators exceeding international standards, providing reliable support for low-temperature operations:

- Mute and Anti-Freezing Idler Rollers: Self-developed low-temperature sealed bearings are adopted, with runout ≤0.4mm (surpassing China's GB standard of 0.5mm), axial displacement ≤0.4mm (surpassing the GB standard of 0.7mm), and rotational resistance ≤2N (surpassing the GB standard of 3N). The operating noise is ≤45dB in a -35°C environment, with a service life of over 50,000 hours, eliminating the need for frequent replacement;

- Anti-Slip and Wear-Resistant Drums: Drive drums and bend drums are made of 40Cr forged material (diameter ≥200mm). The drum shell is processed by a CNC four-roll rounding machine, with ovality <1.5mm. The surface is covered with diamond-patterned rubber, increasing the friction coefficient to 0.45 to avoid belt slipping at low temperatures, and the service life also reaches over 50,000 hours;

- Dust Control Devices: Non-powered dust-collecting chutes are equipped, with 3 layers of guide plates installed inside the chutes to slow down the coal falling speed and reduce air disturbance. Meanwhile, a sealing cover is added at the head of the stacker, achieving a dust collection rate of over 92% and an actual measured concentration of 8.5mg/m³, meeting Russian environmental standards;

- Safety Protection System: It integrates belt deviation switches (standard configuration), dual mechanical limits for wire rope breakage, and emergency pull-cord switches. When an abnormality occurs in the equipment, the hydraulic winch system can automatically lock within 0.01 seconds and trigger an emergency shutdown to avoid safety accidents.

Intelligent Control System

To reduce the intensity of manual operation in permafrost regions, the equipment is equipped with a "PLC automatic stacking + Russian-language remote control" system to achieve "minimal-man operation":

- Automatic Stacking Modes: Two programs—"fan-shaped stacking" and "layered stacking"—are preset. A laser ranging sensor detects the stacking height in real time (accuracy ±50mm) and automatically adjusts the length of the telescopic section and the stacking angle to avoid equipment overload caused by uneven coal accumulation;

- Bilingual Remote Control: A 10-inch touchscreen HMI supports language switching between Russian and English. Operators can remotely control telescoping, rotation, and lifting in a warm control room (within 50 meters of the equipment) without being exposed to the -35°C outdoor environment;

- Fault Self-Diagnosis Function: The system has a built-in 220+ fault diagnosis module. When there is an abnormality in hydraulic pressure or the bearing temperature is too high (>60°C), it automatically alarms and displays the fault location and maintenance suggestions on the HMI, reducing the difficulty of on-site maintenance.

Project Implementation Phases

Design and Production

- Compliance-Oriented Design: SolidWorks 3D modeling software was used to complete the overall equipment design, focusing on simulating and analyzing structural stress and hydraulic flow at low temperatures (simulated equipment deformation ≤0.1mm in a -35°C environment). The design drawings were submitted to the Russian Federal Service for Technical and Export Control for review, and the Equipment Import Permit and EAC Certification were obtained within 30 days.

Precision Production

Core components (idler rollers, drums, PLC controllers) were produced at Zoomry's production base in Zaoqiang, Hebei, in accordance with the ISO 9001 quality management system:

- 10% of each batch of idler rollers was randomly selected for low-temperature rotation testing at -35°C (continuous operation for 72 hours without jamming);

- Ultrasonic testing was conducted on drums after welding, achieving a 100% weld qualification rate;

- During the whole-machine pre-installation phase, the equipment was continuously operated for 120 hours in a factory low-temperature test chamber (-35°C), and 2 cases of hydraulic valve leakage at low temperatures were resolved to ensure no hidden dangers before delivery.

Cross-Border Logistics

Considering the inconvenient logistics and severe winter conditions in Khabarovsk Krai, Zoomry customized a cross-border logistics plan featuring "insulation + positioning + escort":

- Packaging Protection: Equipment modules were packed in thickened insulated containers (with built-in special insulation cotton for -40°C). Hydraulic oil and electrical components were packaged separately and equipped with heating packs to prevent freezing damage during transportation;

- Transportation Route: The equipment was transported by sea (25 days), then transferred to the mining area via rail + road combined transportation (7 days). GPS positioning was used throughout the process, and the transportation status was updated daily;

- On-Site Escort: 2 logistics specialists were arranged to accompany the shipment, coordinating Russian customs clearance and road access permits in permafrost regions to ensure the equipment was delivered without delay or damage.

On-Site Installation and Training

Zoomry dispatched 2 senior engineers to the site to collaborate with the local installation team and advance the work in the -15°C mining environment:

- Before Installation: The flatness of the equipment foundation was tested (error ≤0.1%), and anti-slip pads were added to the hydraulic outriggers to adapt to the permafrost ground;

- Assembly Process: First, the fixed-section frame was assembled, then the telescopic section was connected via the hydraulic winch system, and finally, the electrical and safety systems were commissioned. The assembly of 8 sets of equipment was completed in 20 days;

- Russian-Language Training: A 15-day special training was conducted for 12 operators of the customer, covering "low-temperature startup procedures, key points of daily maintenance (such as idler roller lubrication cycle), and emergency fault handling." Russian-language operation manuals and maintenance videos were provided as support.

Acceptance Testing

- Low-Temperature Operation Test: The equipment was continuously operated for 120 hours in a simulated -35°C environment without faults. The response speed of the hydraulic system was stable (telescopic section movement speed 0.8m/s), and there was no jamming of electrical components;

- Capacity Test: Continuous load operation was conducted for 72 hours. The average handling capacity of a single piece of equipment was 550 TPH, and the average daily handling capacity of 8 sets of equipment reached 1,600 tons, exceeding the 1,500-ton demand;

- Environmental Protection and Safety Test: A third-party organization detected a dust concentration of 8.5mg/m³, meeting the standard of ≤10mg/m³. When scenarios such as belt deviation and wire rope breakage were triggered, the equipment shut down emergently within 0.01 seconds, and the safety protection functions were effective.

Project Achievements

Doubled Production Capacity and Efficiency

- Breakthrough in Daily Capacity: The daily operating capacity of a single piece of equipment increased from 300 tons (original) to 550 tons, and the average daily handling capacity of the entire system reached 1,600 tons. The coal accumulation at the mine wellhead decreased by 90%, and the freeze-thaw deterioration loss dropped from 800 tons per month to 50 tons;

- Shortened Operation Cycle: The full-process cycle of coal from underground mining to stockpiling was shortened from 8 hours to 4.8 hours, increasing the transfer efficiency by 40%. An additional 3 ships (5,000 tons per ship) of coal export transportation can be completed per month.

Significantly Reduced Operation and Maintenance Costs

- Improved Equipment Availability: The equipment availability rate in winter reached 98%, with only 2 shutdowns (totaling 48 hours) due to extreme snowstorms (wind speed >25m/s). There were no shutdowns caused by low-temperature faults, which was 3 percentage points higher than the customer's expected 95% availability rate;

- Optimized Spare Parts and Maintenance Costs: The service life of Zoomry's idler rollers and drums reaches 50,000 hours, and no core components were replaced within 3 months—saving a large amount of spare parts costs compared with the original equipment (which required idler roller replacement every 2 years). The Vladivostok spare parts warehouse enables spare parts delivery within 48 hours, and the average fault repair time is 22 hours, far lower than the 72-hour requirement of the customer.

Compliance with Environmental Standards

- Controllable Dust Emission: The dust concentration in the operation area was stably maintained at 8-9mg/m³, far below the 10mg/m³ standard set by Rosprirodnadzor. The PM10 concentration in residential areas around the coal mine decreased by 35%, and no environmental complaints were received;

- Reduced Noise Pollution: The operating noise of the idler rollers was ≤45dB, a 30% reduction compared with the original equipment (65dB), avoiding noise interference to the indigenous villages around the mining area.

The Technical Director of the Russian coal transportation group stated at the project review meeting: "Initially, we had doubts about the low-temperature adaptability of Chinese equipment, but Zoomry's ZR-SF stackers have completely changed our perception—in the severe winter of -35°C, the equipment can still operate stably and efficiently, and the dust control and safety protection fully comply with Russian standards. More importantly, the global spare parts support and Russian-language training services have solved our worries in the remote mining area. We plan to continue purchasing belt conveyors from Zoomry for the subsequent new coal mine project in Siberia to deepen our cooperation."

ZOOMRY

ZOOMRY