In the bulk material processing sector in Vietnam, a company has been deeply engaged in the transshipment and processing of coal and ore (including iron concentrate, limestone, etc.) for many years. With the continuous expansion of its production capacity, it urgently needs to independently build an exclusive long-distance bulk material conveying line to connect the raw material receiving area and the processing plant. Prior to this, the company relied entirely on third-party trucking services for material transportation and had never established an independently controllable professional conveying system. The core materials to be conveyed include coal (with a moisture content of 8%-12% and a particle size of 0.5-10mm) and ore (iron concentrate with a particle size of 0.1-5mm, limestone with a particle size of 5-20mm). However, the traditional truck transportation mode has become an obvious obstacle to the company's business development.

For the 5,537-meter transportation route, trucks need to go through 4 temporary loading and unloading points for transshipment, which not only increases the comprehensive investment by approximately 35%, but also leads to a coal loss rate as high as 6% and an ore loss rate of 4% due to frequent loading and unloading. The route naturally contains 2 right-angle (90°) bends and 1 gentle slope (15°), requiring additional terrain modification costs for truck passage. The dust emission from open-top transportation reaches 28mg/m³, far exceeding the limit of 10mg/m³ specified in the EU IED and China's GB16297 standards, directly threatening the compliance of the company's export business. The actual transportation capacity of 1,500 tons per hour is seriously out of line with the dynamic production demand of 1,800-4,200 tons per hour, resulting in prominent raw material backlogs during peak periods. More critically, if imported equipment is selected, the spare parts supply cycle is as long as 45 days, with annual downtime exceeding 100 hours and high operation and maintenance costs.

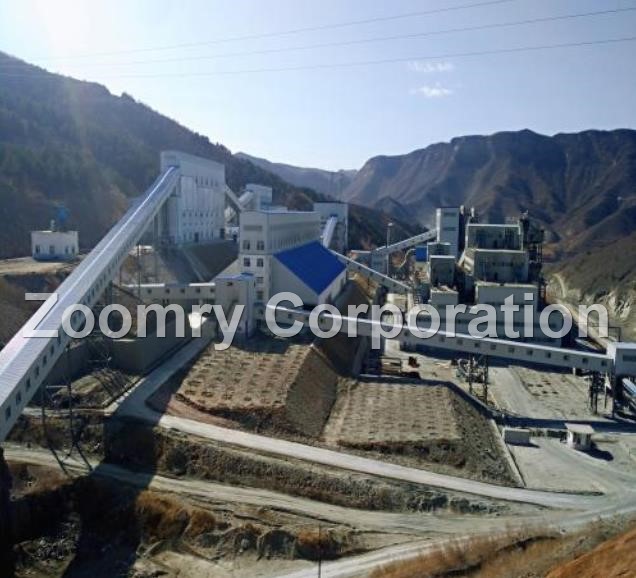

To address these pain points, the company clearly requires suppliers to provide a customized solution featuring "efficient system synergy, flexible terrain adaptation, compliance with global standards, and rapid operation and maintenance response". Leveraging its years of experience in R&D of bulk material conveying equipment, integrated capabilities of full product lines, and international certifications such as ISO 9001 and CE, ZOOMRY has successfully undertaken this project. Through the system design of "multiple terrain-adapted belt conveyors + mobile stacking equipment at process nodes + core components", ZOOMRY has built a closed-loop conveying system covering the entire process of "receiving - conveying - stacking".

Core Project Requirements

Combining the company's actual working conditions and global industry standards, the project has established a demand system around four dimensions, forming clear implementation objectives: In terms of parameter matching, it is necessary to cover the entire 5,537-meter route, with the main line handling capacity of no less than 4,200 tons per hour and the branch line capacity of no less than 1,800 tons per hour. The belt width is adapted to three specifications (1,200mm, 1,400mm, 1,600mm) according to different road sections, while meeting the terrain adaptation requirements for long-distance, steep angle, and curved conveying. In terms of scenario adaptation, the equipment must be compatible with the material characteristics (coal is prone to dust emission, ore causes high wear), and be able to operate stably in Vietnam's extreme environments (high temperature of 40℃ and low temperature of -10℃). In terms of compliance, the dust emission must be controlled within 10mg/m³, the equipment must obtain CE and EAC certifications, and the operation interface must support multi-language switching. In terms of operation and maintenance support, the service life of core components (idlers, rollers) must be more than 50,000 hours, the global spare parts response cycle must not exceed 7 days, and 1-year technical support must be provided.

Based on the above requirements, the project has set four core objectives:

- Efficiency Breakthrough: Realize transshipment-free conveying for the entire 5,537-meter route, ensure the main line and branch line capacities stably meet the standards, and completely replace the truck transshipment mode.

- Environmental Compliance: Reduce dust emission to below 8mg/m³, and control the material loss rates to within 1% (for coal) and 0.8% (for ore) respectively.

- Terrain Adaptation: Adapt to bends and gentle slopes without terrain modification, and ensure the equipment's environmental tolerance meets Vietnam's climatic characteristics.

- Cost Optimization: Keep the annual failure rate below 0.5%, and reduce comprehensive costs through cost-effective equipment and rapid operation and maintenance.

Long Distance Conveying Solution for Coal and Ore

Based on the on-site 3D topographic survey data and material characteristic analysis, ZOOMRY has adopted a design concept of "precision equipment selection by road section + full-process collaborative matching", organically integrating conveying equipment and supporting systems to form a solution adapted to Vietnam's complex working conditions.

Core Conveying Equipment

In response to three typical working conditions along the 5,537-meter route, ZOOMRY has customized three types of differentiated belt conveyors, achieving dual goals of terrain adaptation and material protection through structural optimization.

The long-distance belt conveyor used for the straight section is designed with a 1,600mm belt width, a handling capacity of 4,200 tons per hour, and a belt speed of 4.0m/s, serving as the core conveying unit of the entire system. To cope with the long-distance heavy-load pressure, the equipment adopts a multi-drive system composed of three 315kW variable-frequency motors, with a total power of 945kW. Combined with a hardened gear reducer with a transmission efficiency of ≥96%, it ensures stable power output and controllable energy consumption. The idlers are of the silent type with a diameter of 159mm, and the radial runout is controlled within 0.4mm. The water intake during the 72-hour immersion test does not exceed 95g, making it particularly suitable for Vietnam's humid environment in the rainy season. The belt is made of ST2500 steel cord material, with a tensile strength of ≥2,500N/mm. The 15mm-thick wear-resistant layer can resist ore wear, and the sealed structure with 130mm overlap can effectively suppress dust emission.

The Steep angle belt conveyor configured for the gentle slope section has a belt width of 1,400mm and a handling capacity of 2,800 tons per hour. A combined structure of "35° trough idler group + corrugated sidewall belt" is designed for the 15° slope. Compared with the maximum incline limit of 12° for conventional equipment, it can climb directly without transshipment, shortening the route by 200 meters. The 200mm-high sidewalls and 1.5m-spaced partitions form an effective protection to prevent ore rolling and coal adhesion. The drive unit is equipped with a hydraulic tensioning device that can automatically compensate for the thermal expansion and contraction of the belt, completely solving the slipping problem during heavy-load climbing.

The curved belt conveyor deployed for the bend section has a belt width of 1,200mm and a handling capacity of 1,800 tons per hour. It adopts "self-aligning idler group + flexible turning technology", compressing the turning radius to 30m, which is much lower than the minimum requirement of 80m for conventional equipment. It can adapt to 90° bends without felling vegetation or leveling the ground. The idlers are made of HDPE corrosion-resistant material, with 40% improved wear resistance, which can resist dust erosion during ore transportation. The real-time tension control system can dynamically adjust the belt tension according to the operating status of the bend, ensuring no deviation or material scattering.

Process Node Equipment

To realize the smooth flow of materials from receiving to stacking, ZOOMRY has configured three types of independently developed supporting equipment, which form precise linkage with the core conveyors.

The raw material receiving area adopts the ZRLS-TU1800 Wheel-Type truck unloader, with a 1,800mm belt width adapted to the 50-ton dump trucks commonly used by the company, and a handling capacity ranging from 600 to 1,800 tons per hour. The equipment is equipped with two 6.7° hydraulically adjustable ramps, allowing trucks to unload directly without reversing. The rubber sealing skirts at the bottom of the ramps can effectively reduce dust during unloading. The vibrating feeding device can capture the operating status of the subsequent conveyor through sensors and adjust the unloading speed in real time to avoid material accumulation and blockage risks.

A ZR series hopper feeder is installed between the unloader and the conveyor. The standard 10cbm hopper can be expanded according to needs. The feeding system driven by an 18.5kW variable-frequency motor can realize flow adjustment of 1,800-2,800 tons per hour, ensuring uniform feeding to the conveyor. The inner wall of the hopper is paved with a wear-resistant lining to resist ore wear. The dust cover on the top is combined with a dehumidification device, which can not only reduce dust emission but also prevent coal caking caused by Vietnam's humid climate.

The ZR160SF Radial Telescopic stacker is deployed in the plant stacking area. The 1,600mm belt width corresponds to a handling capacity of 3,000m³/h (equivalent to approximately 2,550 tons per hour based on coal density conversion). The 20-meter stacking height and 10-22-meter telescopic stroke can meet the terminal stacking needs. The equipment supports PLC-controlled automatic stacking modes ("herringbone" and "circular"), reducing manual operation. The lattice-type carbon steel chassis has an excellent strength-to-weight ratio. The hydraulic winch system can lock within 0.01 seconds after power failure, ensuring the safety of open-air operations.

Core Components

All key components are independently produced by ZOOMRY, with performance indicators superior to national standards and CEMA standards. In addition to the idlers standardly equipped with the conveyor, silent idlers with a diameter of 133mm are selected for key parts, with a rotational resistance of ≤2N and an operating noise controlled within 43dB. The rollers are made of 40Cr forged material, and the 219mm-diameter roller body is covered with 12mm-thick diamond-shaped rubber, with a wear life of more than 50,000 hours. After welding, ultrasonic flaw detection and tempering treatment are carried out to eliminate internal crack risks. The cleaning system is equipped with 3 sets of PU scrapers, with a fitting degree of 98% with the belt. Combined with passive dust-collecting chutes and deviation alarm devices, it forms a dual guarantee of "cleaning + safety".

Project Implementation Process

To ensure the accurate implementation of the solution, ZOOMRY adopted a model of "modular implementation + full-cycle management and control", completing installation and commissioning in only 45 days, which is 25% shorter than the industry average cycle.

In the early survey stage, an 8-person technical team spent 15 days completing 3D topographic surveying and mapping, marking gentle slopes, bends, and drainage points using drones and total stations, and optimizing the conveyor laying route. The collected material samples were tested in the laboratory for fluidity and wear resistance, providing a basis for setting parameters such as idler spacing and belt speed. Combined with the company's global layout, the multi-language operation interface and the spare parts allocation plan for the Southeast Asian region were planned in advance.

The production and manufacturing process fully complied with the ISO 9001 and ISO 14001 systems. The rollers of the long-distance conveyor passed the 24-hour static load test with 1.2 times the rated load. The idlers completed 2,000 hours of no-load test operation. The steel cord belts were delivered only after passing the tensile and wear tests. The company sent representatives to participate in the acceptance throughout the process. All equipment passed the CE and EAC certification tests, and the parameters fully met the contract requirements.

The installation and commissioning adopted the mode of "factory pre-assembly + on-site splicing". The 5,537-meter conveyor was divided into 25 modular units, which could be assembled on-site only by bolt connection. The commissioning was carried out in three steps: first, no-load test of individual equipment, then system linkage test, and finally 72-hour full-load test operation. The coal and ore conveying scenarios as well as high-temperature and low-temperature working conditions were simulated, and the PLC program was optimized to the best state.

In the operation and maintenance support stage, 20 days of multi-language training were provided to 15 employees of the company, covering daily maintenance (idler inspection, hydraulic oil level monitoring) and fault handling (belt deviation, motor overload). In view of Vietnam's climatic characteristics, additional special courses such as "motor heat dissipation in high-temperature environment" and "equipment moisture protection in rainy season" were added. ZOOMRY has opened a 24-hour global technical hotline, and relying on regional spare parts warehouses, it can deliver common spare parts within 7 days. Special spare parts are guaranteed through expedited logistics.

Project Results

After commissioning, the system has operated stably for a long time, with all indicators exceeding expectations and creating significant value for the company. In terms of efficiency, the transshipment-free conveying for the entire 5,537-meter route ensures the main line capacity is stably maintained at 4,250 tons per hour and the branch line capacity at 1,850 tons per hour. The conveying cycle is shortened from 8 hours (traditional mode) to 2.5 hours, reducing the annual downtime caused by raw material backlog by approximately 60 hours.

In terms of environmental protection and compliance, the fully sealed design of the system reduces the dust emission to 7.5mg/m³, fully complying with international standards and completely eliminating the compliance risks of the company's export business. The coal loss rate is reduced to 0.9%, and the ore loss rate to 0.7%. Based on the annual conveying volume, the annual material loss is reduced by more than 120,000 tons.

In terms of reliability and cost control, the core components have operated for more than 30,000 hours without large-scale replacement. The annual maintenance frequency is reduced from 15 times to 5 times, and the maintenance cost is reduced by 40%. Compared with the imported equipment solution, the initial investment has more advantages, and the investment payback period is shortened to 2.5 years.

In terms of terrain and environmental adaptability, the equipment successfully adapts to the 15° gentle slope and 90° bends, saving a large amount of civil engineering costs without terrain modification. In the environment of -10℃~40℃, the annual failure rate is only 0.4%, and no major failures have occurred due to extreme weather. The person in charge of the company's project commented: "ZOOMRY's solution not only solves the problem of long-distance conveying, but also eliminates our worries about follow-up operations with rapid operation and maintenance response. We will give priority to cooperation with ZOOMRY for future expansion."

Core Competitiveness of ZOOMRY

- In-depth Scenario Adaptation Capability: In response to Vietnam's complex terrain and climate, ZOOMRY completed the customization of the full set of solutions in only 3 months. Through special designs such as corrugated sidewalls and flexible turning, it achieved precise matching of material characteristics and working condition requirements, shortening the design cycle by 50% compared with the industry average.

- Full-Chain Equipment Synergy Advantage: The full range of equipment from unloaders to stackers is independently developed, with seamless parameter connection to avoid compatibility issues. The core components are independently produced, with better quality controllability and adaptability than outsourced components, ensuring the overall reliability of the system.

- International Compliance and Service System: The equipment has obtained multiple international certifications such as ISO and CE, meeting the compliance requirements of different regions around the world. Relying on multi-regional spare parts warehouses and multi-language technical teams, it realizes 7-day spare parts response and 24-hour technical support, completely solving the operation and maintenance pain points of overseas customers.

ZOOMRY

ZOOMRY