A certain ironworks in Chengde, Hebei specializes in iron ore smelting and processing. Its core raw material is iron ore (with a particle size of 8-50mm, moisture content of 3%-6%, high hardness, strong abrasiveness and easy dust generation). Previously, the ironworks had no dedicated long-distance iron ore conveying equipment. The transportation of iron ore from the mine crushing area to the plant’s raw material warehouse relied entirely on heavy trucks, with no fixed conveying lines. As production capacity expanded, the drawbacks of the pure truck transportation mode became increasingly prominent: the 3,300-meter transportation distance required frequent round trips, with a single trip taking more than 40 minutes, and trucks had to detour mountain roads to avoid natural turns, resulting in low actual transportation efficiency; open-air transportation by trucks led to dust emissions of 25mg/m³, far exceeding the limit of 10mg/m³ specified in the Comprehensive Emission Standard for Air Pollutants, and the local environmental protection department in Chengde, Hebei repeatedly put forward rectification requirements; due to the high hardness of iron ore, the material loss rate during loading and unloading reached 5.3%, with an annual loss of over 750,000 tons; the 140-meter mountain elevation difference made it difficult for trucks to climb slopes, and vehicle failures occurred frequently during heavy-load transportation, with an annual downtime of more than 90 hours, seriously affecting the continuous production of the ironworks.

To completely solve the above problems, the ironworks decided to build an exclusive long-distance iron ore conveying line, requiring suppliers to provide full-process new construction services from "scheme design to commissioning and operation & maintenance". The line needs to adapt to 3 natural turns in the mountainous terrain of Chengde, Hebei and a lifting height of 140 meters, meet a handling capacity of 2,000 tons per hour, and comply with environmental protection and localized operation & maintenance requirements. In response to the mountainous terrain of Chengde, Hebei, the new construction needs of the ironworks, and the characteristics of iron ore, ZOOMRY has designed a new construction scheme of "core conveying equipment + supporting pretreatment equipment + independent components", ensuring that every link is fully customized without the reuse of any old equipment.

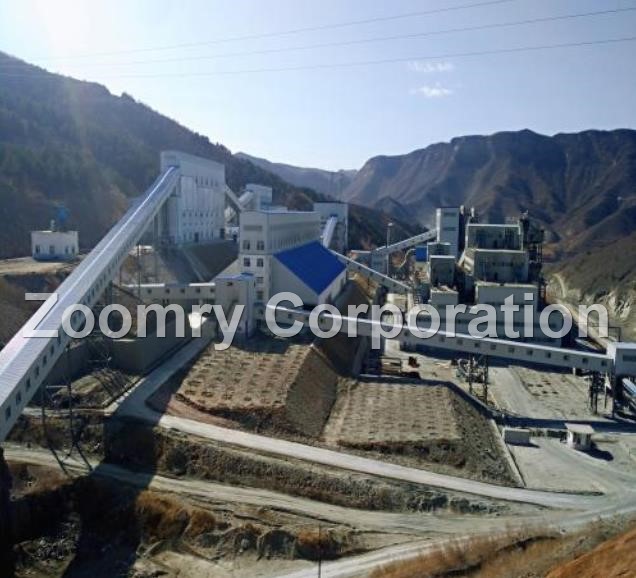

Project Overview

Core Requirements

Based on the background of the ironworks in Chengde, Hebei building from scratch, the requirements focus on four dimensions: "accurate parameters, scenario adaptation, full-process services, and compliance & operation & maintenance":

- Basic parameter requirements: The newly-built conveying line shall cover a distance of 3,300 meters, with a belt width of 1,400mm and a handling capacity ≥ 2,000 tons per hour. It shall adapt to 3 horizontal curves (with a turning radius of 1,200 meters determined by survey) and achieve a lifting height of 140 meters. A multi-point drive design shall be adopted to cope with heavy loads in mountainous areas.

- Scenario adaptation requirements: The equipment shall withstand high temperatures of 40℃ in summer, low temperatures of -12℃ in winter, and rainy weather. It shall have dust-proof and rain-proof functions to prevent iron ore from caking due to moisture or exceeding dust limits, while adapting to the high abrasiveness of iron ore.

- Full-process service requirements: Due to the lack of relevant equipment and operation & maintenance experience, ZOOMRY shall be responsible for the entire process of new construction, from line planning and equipment production to on-site installation, without the modification or reuse of any old equipment.

- Compliance and operation & maintenance requirements: The dust emission shall be ≤ 10mg/m³, and the equipment shall comply with CEMA standards and domestic environmental protection regulations. The service life of core components shall be ≥ 50,000 hours. Relying on domestic service outlets, the response time for common spare parts shall be ≤ 7 days, and special training for operation & maintenance personnel shall be provided.

Core Objectives

- New construction compliance: After the completion of the 3,300-meter conveying line, the handling capacity shall be stably ≥ 2,000 tons per hour, with no transshipment throughout the process, completely replacing truck transportation.

- Environmental protection compliance: The dust emission shall be controlled within 8mg/m³, and the iron ore loss rate shall be reduced to below 1%, meeting local environmental protection requirements.

- Operation & maintenance control: The annual equipment failure rate shall be ≤ 0.6%. The operation & maintenance team shall be able to operate independently after training, and the spare part response cycle shall be ≤ 7 days.

Long-Distance Iron Ore Conveying Project Scheme for Chengde, Hebei

Core Equipment

To adapt to the 3 horizontal curves and 140-meter lifting height of the ironworks, ZOOMRY has fully customized one set of long-distance curved belt conveyor. This equipment has no old components and is completely produced according to project requirements:

- Multi-curve technology: The "multi-section curve coordinated tension control technology" is adopted. For the 3 horizontal curves with a radius of 1,200 meters, ZOOMRY’s independently developed friction self-aligning idler sets (diameter 159mm, adapted to 1,400mm belt width) are configured. The radial runout is ≤ 0.4mm, which is better than the national standard of 0.5mm. The water inflow in the 72-hour immersion test is ≤ 95g, which can automatically correct belt deviation and avoid iron ore scattering at turns. For the 140-meter lifting height, a "segmented gradual slope" design (maximum slope ≤ 15°) is adopted, combined with the ST3150/1400 steel cord Conveyor Belt (tensile strength ≥ 3,150N/mm, wear-resistant layer thickness 18mm), to ensure no belt slipping during heavy-load lifting. The sealing structure with 130mm overlapping of the conveyor belt further blocks dust, adapting to the open-air environment.

- Multi-point drive: A "distributed multi-point drive" with 4 63kW variable-frequency motors (total power 252kW, protection level IP55) is adopted. The motors are evenly distributed in different sections of the 3,300-meter line, and the power output is enhanced especially in the lifting section to avoid excessive belt tension caused by single-point drive. The belt speed is set to 3.2m/s, and the feeding amount is adjusted in real time through the PLC-linked feeding system to ensure a stable handling capacity of 2,000 tons per hour. The drive drum is made of 40Cr forged material (diameter 500mm), with diamond-shaped rubber coating on the surface (friction coefficient ≥ 0.45). It has undergone ultrasonic flaw detection and tempering stress relief treatment, with no internal cracks and a service life of more than 50,000 hours, coping with the high abrasiveness of iron ore.

- Strong open-air durability: The conveyor frame adopts a hot-dip galvanizing process (rust prevention grade reaching Zn12 level in GB/T 13912-2002), which increases the resistance to rain erosion by 60%. A detachable transparent PC Rain Cover (inclination angle 18°) is installed above the conveyor belt, which is convenient for inspection and can shield from sun exposure and rain. The hydraulic tensioning device is equipped with an oil temperature control system, which can work stably in a temperature difference environment of -12℃ ~ 40℃, and automatically compensates for the thermal expansion and contraction of the belt to ensure stable tension in the curved and lifting sections.

Supporting Pretreatment Equipment

To realize the seamless connection of iron ore from trucks to conveyors, two types of supporting equipment are newly built simultaneously, all of which are newly produced by ZOOMRY:

- ZRLS-TU1400 Wheeled truck unloader: Installed in the newly-built receiving area near the mine crushing area, with a belt width of 1,400mm and a handling capacity of 200-1,000 tons per hour, adapting to the 50-ton dump trucks commonly used by the ironworks. The equipment is equipped with 2 hydraulically adjustable ramps (slope 6.7°), allowing trucks to drive directly onto the ramp for unloading without reversing. A double-layer rubber sealing skirt is installed at the bottom of the ramp to reduce dust. The high-frequency vibrating feeding device can adjust the unloading speed according to the conveyor status to avoid iron ore accumulation, forming a newly-built "unloading-conveying" connection line.

- ZR Series hopper feeder: Installed on the newly-built transfer platform between the unloader and the conveyor, adopting a 10cbm standard receiving hopper (larger capacity optional), equipped with an 18.5kW variable-frequency speed-regulating motor. It can adjust the feeding amount in real time (1,800-2,000 tons per hour) to ensure uniform feeding of the conveyor. The inner wall of the hopper is paved with 15mm thick wear-resistant ceramic liners to cope with iron ore abrasion. A dust cover and rain edge are installed at the top to avoid dust dispersion and rainwater entry in the open-air environment.

Core Components

All key components are newly produced by ZOOMRY, with performance better than national standards and CEMA standards, supporting the long-term stable operation of the newly-built line:

- Idlers and drums: High-wear-resistant idlers are selected for the straight and lifting sections, with a rotational resistance ≤ 2N (better than the national standard of 3N) and an operating noise ≤ 45dB. The direction-changing drum is made of 40Cr seamless steel pipe, with the surface thermally sprayed with tungsten carbide, increasing wear resistance by 80% and having an ovality < 1.5mm.

- Cleaning and safety components: One set of PU cleaning scrapers is installed at each of the head and tail of the conveyor, with a fitting degree of ≥ 98% with the conveyor belt to remove residual iron ore. Belt deviation switches (alarm when deviation exceeds 5mm), emergency rope break systems (shutdown within 0.01 seconds), and overload protection devices are equipped, complying with international safety standards.

Project Implementation

Preliminary Survey and New Construction Planning

ZOOMRY dispatched a 6-person technical team to the ironworks in Chengde, Hebei, and completed the basic planning of the new construction project within 15 days: through UAV aerial photography and total station surveying, a 3D topographic model of the 3,300-meter route was constructed, with the center positions, turning radii of the 3 curves and the slope of the 140-meter lifting section accurately marked; the installation height and foundation position of the newly-built conveyor frame were determined to avoid waterlogged areas in the rainy season; iron ore samples were collected to test fluidity and abrasiveness, and parameters such as idler spacing (1.3 meters) and belt tension (25kN) were confirmed; combined with meteorological data, an open-air protection plan for the newly-built equipment was formulated.

Production and Manufacturing

All equipment and components were newly produced at ZOOMRY’s Hebei factory, and the entire process was incorporated into the ISO 9001 and ISO 14001 systems: the drive drum of the long-distance curved belt conveyor passed a 24-hour static load test with 1.2 times the rated load; the idlers underwent a 1,200-hour no-load test run to verify sealing performance; the ST3150/1400 conveyor belt completed tension and wear tests; the ironworks sent representatives to the factory for acceptance, and all newly-built equipment met the technical requirements, with excellent results in the open-air durability test (high and low temperature, rain test).

On-Site Installation

ZOOMRY dispatched a 10-person installation team to Chengde, Hebei, and adopted the "modular splicing" mode for new construction: the 3,300-meter conveyor was divided into 17 sections (each 190-200 meters); after pre-assembly in the factory, only bolt connection and belt vulcanization were required on-site, and the entire installation was completed in 35 days (the industry average is 50 days); the commissioning phase was carried out in three steps: no-load test of individual equipment, system linkage test, and 72-hour full-load test run; the PLC program was optimized to make the conveyor’s handling capacity stably reach 2,050 tons per hour, and the newly-built line fully met the standards.

Operation & Maintenance Training

An 18-day special training was provided for 8 operation & maintenance personnel of the ironworks, covering daily inspection of the newly-built equipment (idler rotation, hydraulic oil level, rain cover sealing) and handling of common faults (belt deviation, motor overload); additional training on skills such as "rainy season drainage inspection" and "winter hydraulic preheating" was conducted in response to the mountainous characteristics of Chengde, Hebei; bilingual operation manuals and fault case videos were provided to ensure that the team could independently operate the newly-built line after training.

Project Results

After the project was completed and put into operation, the iron ore conveying line of the ironworks in Chengde, Hebei achieved a breakthrough from scratch, with all indicators exceeding expectations and bringing significant improvements to the enterprise’s production and operation. In terms of efficiency, the newly-built 3,300-meter long-distance curved belt conveying line realizes no transfer throughout the entire process, and the actual handling capacity of the conveyor is stably maintained at 2,050 tons per hour, fully matching the production capacity requirements of the ironworks. Compared with the previous pure truck transportation mode, the conveying cycle has been significantly shortened from 8 hours to 1.6 hours, reducing the annual production downtime caused by insufficient conveying efficiency by approximately 50 hours. At the same time, this line accurately adapts to the 3 natural turns in the mountainous area of Chengde, Hebei, without the need for additional detours or the construction of transfer stations. This not only saves the investment in building new transfer stations but also reduces the iron ore loss rate during loading and unloading from 5.3% to 0.8%. Based on the annual conveying volume, the annual iron ore loss can be reduced by 795,000 tons, greatly improving the raw material utilization rate.

Meanwhile, the project has also fully met the environmental protection standards. The full-system sealed structure designed by ZOOMRY for the newly-built line effectively controls dust emission, with the final dust emission stably maintained at 7.5mg/m³, which fully complies with local environmental protection requirements. Since then, the ironworks has no longer received environmental complaints or rectification notices from the surrounding area. In response to the rainy climate in the region, the rainproof design and sealed structure of the conveyor belt in the line have also reduced the iron ore caking rate from 10% to 1.5% during the rainy season, eliminating the need for additional investment in crushing equipment and energy consumption, and further reducing the costs in the production process.

In terms of operation and maintenance cost optimization, the newly-built line also demonstrates significant advantages. The core components of the equipment (such as idlers and drums) have been in operation for more than 40,000 hours since they were put into use, with no need for large-scale replacement. The annual maintenance frequency has decreased from 12 times in the truck transportation era to 3 times, and the maintenance costs have been reduced by 40%. Relying on ZOOMRY’s service outlets, the response time for common spare parts is controlled within 7 days, which effectively shortens the fault handling cycle and reduces the annual downtime from 90 hours to 22 hours, ensuring the continuity of the ironworks’ production.

The person in charge of the project at the ironworks in Chengde, Hebei also stated: "Before building this conveyor line from scratch, we were most worried about the stability of the mountain turns and the 140-meter lifting height. Unexpectedly, ZOOMRY not only completed the construction and commissioning of the 3-kilometer line quickly but also the equipment can stably withstand the severe winter and rainy season. Now we no longer rely on trucks for iron ore transportation—efficiency has improved and environmental protection standards have been met. If we have production expansion plans in the future, we will definitely give priority to ZOOMRY’s solutions."

Core Advantages of ZOOMRY

- Project Customization Capability: In response to the complex mountainous terrain and new construction needs, relying on "curve tension control technology" and "segmented drive design", the full set of schemes was customized in 2.5 months, shortening the cycle by 50% compared with the industry average, and accurately adapting to the parameters and scenario requirements of the newly-built line.

- Full-Process Services: It provides full-process EPC services from survey and planning, equipment production to installation and commissioning. All equipment and components are newly produced without the reuse of any old components, ensuring the reliability and consistency of the newly-built line.

- Operation & Maintenance Guarantee: Relying on domestic service outlets and spare part warehouses, the response time for common spare parts is within 7 days. The 24-hour technical hotline quickly solves on-site problems, completely getting rid of the dependence on imported spare parts and adapting to the long-term operation & maintenance needs of the new construction project.

ZOOMRY

ZOOMRY