Specification:

Capacity

300-500m3/h

motor Power

220kw

Gauge

30-60m

Description:

A form of continuous unloading or loading equipment for bulk commodities, the combination chain bucket unloader can employ a chain bucket to remove materials from a train wagon and belt conveyors to move them outside the machine. It runs consistently: The constant working mode is the main cause.

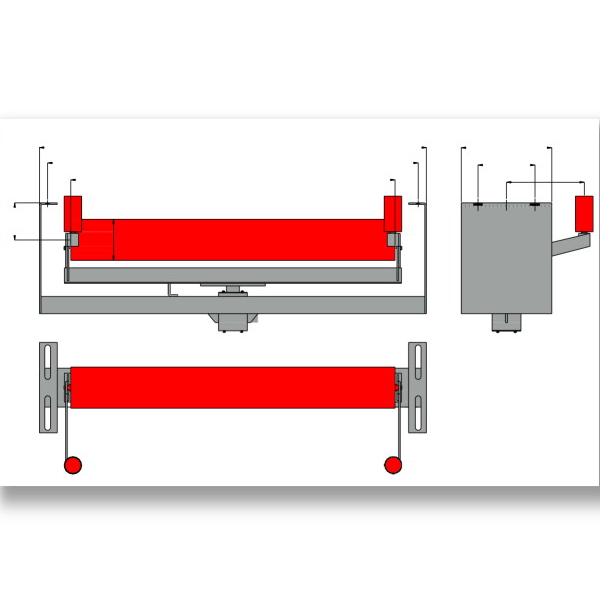

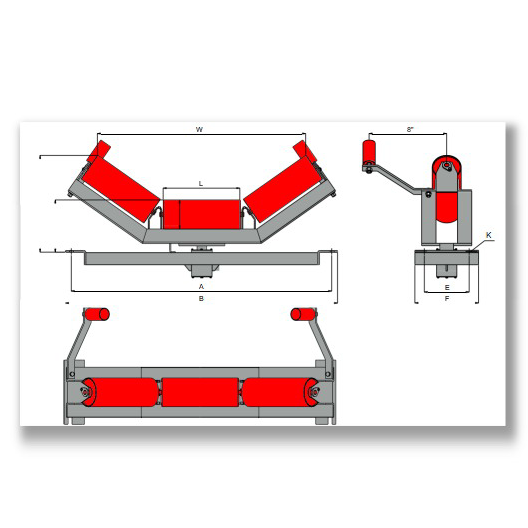

The following components make up the Combine chain bucket unloader: Mechanisms for lifting chains, rotating and traveling, eliminating dust, and using an electric control system. The material is transported to the end of the unloader by the belt conveyor after being raised by the machine from a railway carriage. To go to its destination, the material is fed evenly and gradually into the ground belt conveyor through the funnel.

To extract enormous quantities of material like iron, stone, limestone, grains, and coal, a combined chain bucket unloader is employed. The product's maximum cubic meter per hour rate of material unloading is 500 m3/h. A conveying system is used by the Combined Chain Bucket Unloader to move materials. This machine is environmentally beneficial because the dust collection equipment is mounted above the belt conveyor. Depending on the size of the equipment, this product uses 140KW or 220KW of power. In comparison to traditional ways, this machine has made the unloading and loading process more time and cost efficient. As a result, this device is now required by major production industries.

ZOOMRY

ZOOMRY