ZOOMRY Low Feed hopper feeder is a specialized equipment developed to address core pain points in global bulk material handling scenarios, such as "limited lifting capacity of feeding equipment, low-ceilinged operating spaces, and easy material scattering". It can efficiently connect front-end small and medium-sized feeding equipment (e.g., wheel loaders, small excavators, grab cranes) with back-end processing equipment (belt conveyors, telescopic stackers, truck unloaders, Mobile Ship Loaders), providing domestic and foreign customers with an integrated bulk material handling solution featuring "low-height adaptation + wide-range feeding + controllable conveying".

With "low feed height" as its core design concept, the Low Feed hopper feeder balances efficient feeding performance and space adaptability: the hopper capacity ranges from 7-12 m³ in the horizontal stacking state, with a maximum handling capacity of up to 800 tons per hour (TPH). It is equipped with a 20-28 m hydraulically adjustable tilting arm, capable of stably handling various bulk materials such as aggregates, ores, biomass (e.g., wood chips, straw), and coal with a particle size of ≤200 mm. Its unique wide feed inlet and rear feeding structure can perfectly adapt to low-ceilinged operating spaces and small/medium-sized feeding equipment, enabling the feeding process without additional material lifting devices. This completely solves the problems of "difficult feeding and large space occupation" of traditional high-hopper equipment, and has now become a core bulk material handling equipment for low-feed scenarios such as underground mines, low-ceilinged workshops, and small/medium-sized material yards.

Core Features of ZOOMRY Low Feed Hopper Feeder

The design of ZOOMRY Low Feed Hopper Feeder revolves around three core goals: "low-height adaptation, high feeding efficiency, and low material loss". Both the equipment structure and functional system have been deeply optimized for low-feed scenarios to ensure stable and efficient operation in limited spaces.

The low feed height design fundamentally solves the problem of insufficient lifting capacity of small and medium-sized feeding equipment. The minimum height of the equipment's feed inlet can directly adapt to the discharge height of 20-30 ton class small/medium-sized wheel loaders, eliminating the need for additional material lifting equipment. This not only reduces equipment investment costs but also simplifies operation links. At the same time, its overall height is more than 30% lower than that of traditional hopper feeders, allowing normal operation even in low-ceilinged environments with a clear height of 2.5 m (e.g., underground mine roadways, workshops with limited ceiling height) without the need to modify the operating site, significantly reducing the investment in early-stage site construction.

The hopper adopts a dual-design scheme of "wide feed inlet + rear feeding". The width of the feed inlet is 3.5-4.2 m, adapted to the hopper capacity, which greatly expands the feeding coverage area. Small and medium-sized feeding equipment can complete discharging without precise alignment, effectively reducing the time spent on equipment alignment. The rear feeding structure is more in line with the needs of site layout: the equipment can be placed directly close to material piles or feeding points, shortening the movement distance of feeding equipment. At the same time, it avoids material scattering during the "turning and discharging" process, increasing the material utilization rate by more than 15%.

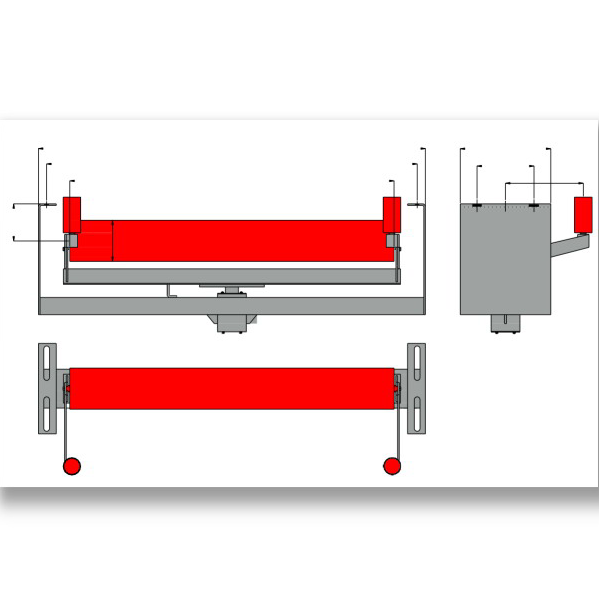

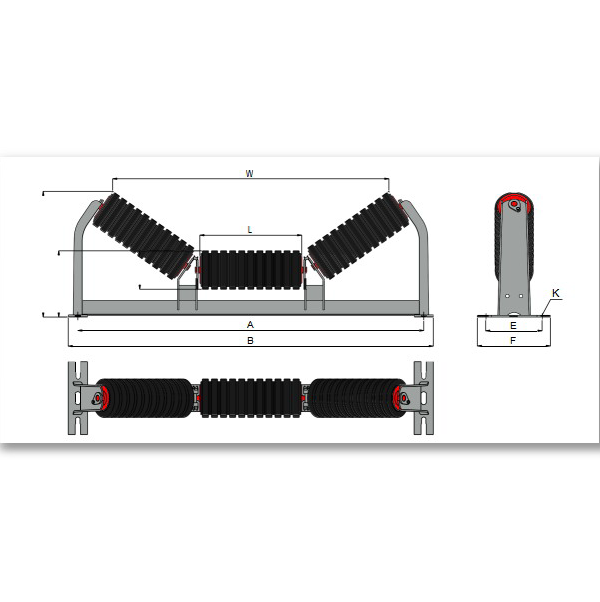

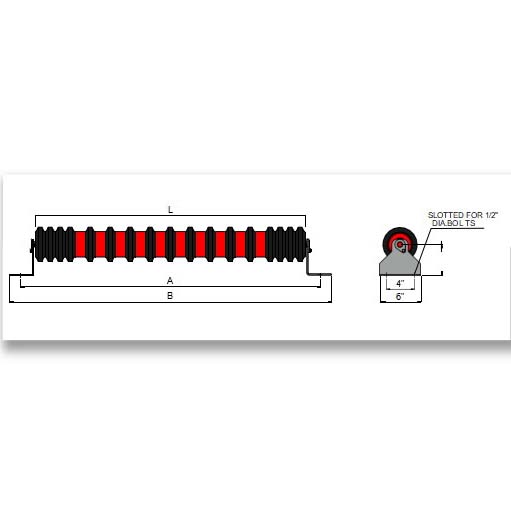

The equipment is equipped with a controllable feeding system to ensure uniform and stable material output. The feeding belt is a 1200 mm wide EP 500 type 3-layer structure, composed of a 5 mm base belt and a 1.5 mm wear-resistant layer. It has excellent tensile and wear-resistant properties, and can adapt to the conveying needs of different types of materials such as aggregates and biomass. The system is also equipped with a variable frequency drive (VSD), which can realize stepless speed regulation of 0-800 TPH. The feeding speed can be dynamically adjusted according to the actual handling capacity of back-end belt conveyors and telescopic stackers, avoiding material blockage caused by excessive feeding speed and preventing capacity waste caused by too slow feeding speed. In addition, the height-adjustable side skirts on both sides of the belt can further reduce material scattering during conveying, lowering the workload of on-site cleaning.

Detailed Technical Parameters of Low Feed Hopper Feeder

| Core Parameters | Specification Range | Remarks (Based on Industry General Standards) |

|---|---|---|

| Hopper Capacity (Horizontal Stacking) | 7-12 m³ | Capacity can be increased to 9-14.5 m³ in the stacked state, calculated based on a material bulk density of 1.6 t/m³, including a standard feed inlet extension structure |

| Maximum Handling Capacity | Up to 800 TPH (Tons Per Hour) | Designed for aggregates and ores; when handling light materials such as biomass, the output rate can be adjusted according to material bulkiness |

| Adaptable Feeding Particle Size | ≤200 mm (Millimeters) | Can receive materials of this particle size conveyed by small/medium-sized wheel loaders, excavators, and grab cranes, no additional crushing pretreatment required |

| Feeder Belt Specification | 1200 mm Wide, EP 500 Type, 3-Layer | 5 mm base belt + 1.5 mm wear-resistant layer, with a tear strength of 500 N/mm, adapting to the wear needs of various materials |

| Tilting Arm Length | 20-28 m | Adopts a folded plate structure, supporting hydraulic folding and front lifting, facilitating transportation and adjusting discharge height to meet the feeding needs of different back-end equipment |

| Maximum Discharge Height | 9.1-13.4 m (Adapted to Tilting Arm Length) | A 20 m tilting arm corresponds to a maximum discharge height of approximately 9.1 m, and a 28 m tilting arm corresponds to approximately 13.4 m, matching the height of back-end equipment such as belt conveyors and mobile ship loaders |

| Minimum Feed Height | 1.2-1.5 m (Adjustable) | Adapts to the discharge height of small/medium-sized wheel loaders (20-30 ton class), no additional lifting equipment required |

| Drive Method | Single/Dual motor Drive (Electric/Hydraulic Optional) | Electric drive is suitable for fixed operation scenarios with stable power supply; hydraulic drive is suitable for temporary operations without external power supply, meeting different energy conditions |

| Applicable Materials | Aggregates, Ores, Biomass, Coal, Cement Clinker | Not recommended for high-viscosity materials such as wet clay to avoid hopper blockage and belt adhesion |

| Protection Level (Electrical Control Part) | IP65 (NEMA-4 Class) | Includes a timer, emergency stop button, and cold start function, adapting to harsh environments such as high dust in quarries and high humidity in ports |

Core Applicable Scenarios of Low Feed Hopper Feeder

With the characteristics of "low-height adaptation, wide feeding range, and multi-material compatibility", ZOOMRY Low Feed Hopper Feeder has served customers in more than 50 countries and regions around the world, and is widely used in various scenarios with low-feed requirements.

Small and Medium-Sized Quarries

Quarries mostly use 20-30 ton class wheel loaders and small excavators for feeding operations. Traditional high-hopper equipment often requires additional elevators to complete feeding, which not only increases costs but also prolongs the operation process. The 1.2-1.5 m low feed height of ZOOMRY Low Feed Hopper Feeder can be directly connected to such small/medium-sized feeding equipment. Combined with the wide feed inlet design, loaders can discharge without precise alignment; the 20-28 m tilting arm can also directly convey aggregates to belt conveyors or telescopic stackers, realizing seamless connection of "feeding - conveying - stacking" and significantly improving the overall operation efficiency.

Low-Ceilinged Operation Areas in Ports

Some areas of ports, such as old terminals and indoor warehouses, have limited ceiling height, making it difficult to install traditional high-hopper equipment. ZOOMRY Low Feed Hopper Feeder has a low overall height and can operate normally in environments with a clear height of 2.5 m; the rear feeding structure allows the equipment to be placed close to the edge of the terminal. Equipped with a 20-28 m tilting arm, it can directly convey materials such as coal and cement clinker to mobile ship loaders or truck unloaders, meeting loading and unloading needs without site modification. At the same time, the wide feed inlet design can reduce material scattering, lowering the cleaning cost of the port site.

Biomass Yards

Small grab cranes or loaders are commonly used for feeding in such yards. Biomass materials (e.g., wood chips, straw) are loose and easy to scatter, and excessive compression and crushing should be avoided. The low feed height of ZOOMRY Low Feed Hopper Feeder can reduce the impact of falling materials, preventing biomass crushing; a material agitator can be added as needed to avoid material agglomeration; the optional herringbone pattern belt can improve the stability of biomass during conveying and prevent slipping, ensuring uniform feeding at a handling capacity of 800 TPH, which meets the continuous feeding needs of scenarios such as biomass power plants and organic fertilizer plants.

Underground Mines

Roadways in underground mines usually have a clear height of only 2.5-3 m, making it impossible for traditional feeding equipment to enter for operation. The low-height design of ZOOMRY Low Feed Hopper Feeder allows direct installation in roadways, and the rear feeding structure can also adapt to the roadway layout; the 7-12 m³ hopper capacity can temporarily store ores (particle size ≤200 mm) crushed in mines. The 20 m tilting arm conveys materials to underground belt conveyors, reducing the number of round trips of loaders in roadways, which not only lowers safety risks but also reduces fuel consumption.

Why Choose ZOOMRY

Multi-Dimensional Customization

ZOOMRY Low Feed Hopper Feeder supports multi-dimensional customized configurations, which can be flexibly adjusted according to specific operation scenarios and material characteristics. For high-wear materials such as ores, the hopper inner lining can be 6 mm hardened steel or 15 mm ULF wear-resistant material to extend the service life of the equipment; for biomass materials, a dedicated agitator and herringbone belt can be added to solve the problems of material agglomeration and slipping; if the operation scenario has high requirements for dust control (e.g., food raw material yards), a canvas or galvanized dust cover can be added to the tilting arm to reduce dust pollution. At the same time, the equipment also supports fine adjustment of the feed height to adapt to different models of small/medium-sized feeding equipment.

Multi-Equipment Collaboration

ZOOMRY has a complete bulk material handling equipment matrix, covering belt conveyors, telescopic stackers, mobile ship loaders and other products. The Low Feed Hopper Feeder has reserved linkage interfaces with the full range of products during the design stage, including mechanical adaptation structures and communication interlocking devices, without the need for additional customized adapter components. If customers purchase multiple types of equipment at the same time, they can directly realize synchronous start and stop of "feeding - conveying - stacking/loading" after delivery. For example, when the Low Feed Hopper Feeder is linked with a belt conveyor, the feeding speed and conveying speed can be dynamically matched through preset parameters, effectively avoiding material accumulation.

Lower Costs

In terms of cost control and service response, relying on a complete domestic supply chain system, ZOOMRY Low Feed Hopper Feeder has significant advantages in cost, and its equipment price is more in line with the budget needs of global small/medium-sized customers. At the same time, the equipment transportation plan has been optimized: it can be disassembled and loaded into 40-foot (12 m) high-cube containers, or transported by ro-ro shipping, reducing global transportation costs. In terms of technical support, through cooperation with local logistics providers in major markets such as Asia, Europe, and the Americas, "72-hour spare parts delivery" can be realized; the 24/7 online remote diagnosis team can quickly locate equipment faults, and combined with the collaboration of local engineers, the equipment downtime can be controlled within 48 hours.

Easy Maintenance

ZOOMRY Low Feed Hopper Feeder adopts a modular design: the power unit, feeding system, and tilting arm can be disassembled independently. Daily maintenance (such as belt replacement and motor maintenance) does not require overall disassembly of the equipment, reducing maintenance man-hours. The control panel integrates multi-language interfaces including Chinese, English, Spanish, and Russian, adapting to the operating habits of operators in different regions; at the same time, a detailed maintenance manual is provided, allowing the customer team to independently complete basic maintenance work such as belt tension adjustment, lubricating oil addition, and hopper cleaning, reducing dependence on external technical personnel, and the long-term use cost is significantly lower than that of traditional equipment.

ZOOMRY's Customer Support and Service Guarantee

To ensure the efficient operation of the Low Feed Hopper Feeder, ZOOMRY has built a full-process support system from selection to after-sales around customer needs.

In the selection consultation stage, customers only need to provide information such as the operation scenario (e.g., underground mine, biomass yard), feeding equipment model, and handling capacity requirements. ZOOMRY's technical team will formulate a customized selection plan through "material characteristic analysis + site space simulation", covering hopper capacity selection, recommendation of customized components (e.g., dust cover, agitator), and equipment placement planning, effectively avoiding efficiency waste caused by improper selection.

In the installation and training support link, a detailed installation manual is attached when the equipment is shipped; the technical team provides 24-hour remote installation guidance services, and can answer questions during the installation process in real time through video calls; if customers have needs, engineers can also be dispatched to the site to assist in installation and commissioning. Domestic customers can receive on-site support within 24 hours, and on-site support for international customers can also be responded to within 72 hours. At the same time, 1-2 days of on-site training will be provided for operators, covering equipment operation specifications, parameter adjustment methods, emergency handling procedures, etc., to ensure that operators can independently operate the equipment.

In terms of after-sales operation and maintenance guarantee, the equipment is equipped with an IP65-grade control panel that supports real-time data transmission. The technical team can remotely view the equipment operation parameters 24 hours a day. 80% of common faults (such as motor overload and belt deviation) can be solved through remote guidance; common spare parts (such as belts, drive motors, and hopper linings) are pre-stored by local logistics providers and can be delivered within 72 hours after the customer places an order. Special spare parts can also be supplemented urgently through international air transportation; after the equipment is put into operation, ZOOMRY will conduct regular return visits at three time points: 3 months, 6 months, and 12 months, to understand the equipment operation status and provide professional maintenance suggestions (such as belt replacement cycle and lubricating oil model selection) to help customers extend the service life of the equipment.

ZOOMRY

ZOOMRY