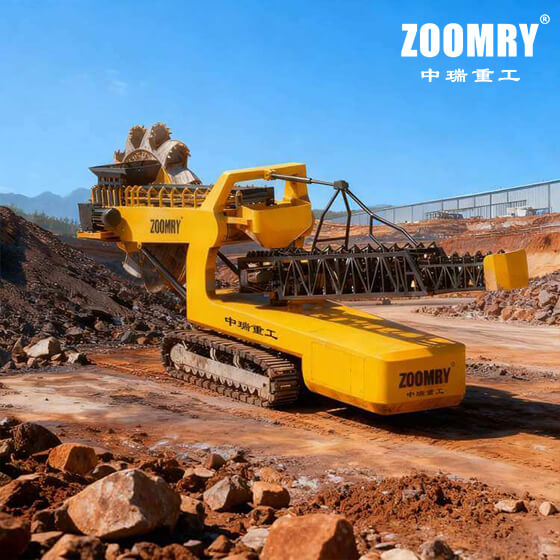

ZOOMRY Static hopper feeder is a static and high-efficiency equipment developed for global bulk material handling scenarios. It can seamlessly connect front-end feeding equipment (wheel loaders, grab cranes, excavators) with back-end conveying/processing equipment (belt conveyors, telescopic stackers, Mobile Ship Loaders, truck unloaders), building an integrated bulk material handling system for domestic and foreign customers.

With "static feeding" as its core design concept, the Static hopper feeder not only features stable conveying performance but also offers flexibility in scenario adaptation: the hopper capacity ranges from 5-15 m³ (horizontal stacking), with a maximum handling capacity of up to 1000 tons per hour (TPH). It supports the "direct feeding and discharging by front-end equipment" mode, fundamentally reducing material transfer links. Meanwhile, it is compatible with two installation methods (fixed and wheeled) and can handle various bulk materials such as sand, aggregates, ores, cement clinker, and coal. It not only meets the needs of long-term fixed operations but also adapts to the adjustment of temporary material transfer. Currently, it has served customers in more than 50 countries and regions worldwide, and has become a core supporting equipment for ZOOMRY's belt conveyors, scraper feeders and other products.

Core Application Scenarios

Relying on high adaptability and stability, ZOOMRY Static Hopper Feeder plays a core role in various bulk material handling scenarios, meeting the operational needs of different industries:

Quarries

In the aggregate handling process of quarries, crushed materials need to be quickly connected to screening and washing equipment. Traditional operations rely on repeated transfer by loaders, which is not only inefficient but also prone to excessive crushing of aggregates. ZOOMRY Static Hopper Feeder can be installed between the crusher and the belt conveyor. Loaders directly discharge the crushed materials into the hopper, and the materials are smoothly conveyed to the screening equipment through the static feeding system, realizing "crushing-feeding-screening" in one step and reducing losses and labor input in the transfer link.

Ports

In the ore and coal loading/unloading operations at port terminals, the discharge volume of grab cranes fluctuates. If directly connected to back-end ship loading equipment, it is easy to cause material blockage or equipment idleness. The Static Hopper Feeder can act as a "buffer hub": it temporarily stores materials unloaded by grab cranes through the hopper, and then supplies materials to the ship loading equipment at a stable speed via the controllable feeding system. This not only improves ship loading efficiency but also reduces material dust scattering, making it suitable for the high-humidity and high-dust operating environment of ports.

Mines

In mine raw material pretreatment scenarios (such as ore transfer), the operating environment is harsh (high dust, high humidity), and strict requirements are imposed on equipment failure rates. The static design of ZOOMRY Static Hopper Feeder reduces transmission components, and its electrical control part reaches IP65 protection rating, which can resist the impact of dust and moisture. With a mean time between failures (MTBF) of over 8000 hours, it can realize 24-hour continuous operation and significantly reduce maintenance frequency.

Building Material Factories

In the production of building material factories, materials such as cement clinker and sand need to be conveyed to the production line in a fixed proportion, and the stability of feeding speed directly affects product quality. ZOOMRY Static Hopper Feeder uses a variable frequency drive to control the feeding speed error within ±5%. It can accurately supply materials to the batching machine, ensuring the stable proportion of clinker and other raw materials and helping to improve the qualification rate of final products.

Core Performance Advantages of Static Hopper Feeder

Significantly Reduces Secondary Material Handling

In traditional bulk material handling, materials need to be stacked in temporary piles by loaders and then transferred to conveying equipment. This process is not only time-consuming but also causes aggregate crushing loss due to collision. ZOOMRY Static Hopper Feeder supports the "direct feeding by front-end equipment" mode: wheel loaders, grab cranes and excavators can discharge materials directly into the hopper, and the materials are conveyed to back-end equipment through the static system, eliminating the temporary stacking link. The comprehensive operation efficiency is increased by more than 40%, while reducing material loss and labor costs.

High Productivity and Controllable Feeding

For high-productivity scenarios such as ports and large quarries, the equipment has a maximum handling capacity of up to 1000 TPH and is equipped with a variable frequency drive system to achieve "controllable feeding". Operators can accurately adjust the feeding speed (stepless adjustment from 0 to 1000 TPH) according to the handling capacity of back-end belt conveyors and telescopic stackers. This not only avoids material blockage caused by excessive feeding speed but also prevents idleness of back-end equipment due to too slow feeding speed, ensuring smooth connection of the entire operation process.

Flexible Hopper Capacity

The hopper capacity of the equipment ranges from 5-15 cubic meters (horizontal stacking), and the capacity can be increased to 6.3-18 cubic meters in the stacked state (based on a material bulk density of 1.6 tons/cubic meter). It can be flexibly selected according to the specifications of front-end feeding equipment: 5-8 cubic meters for small-scale operation scenarios, and 12-15 cubic meters for large-scale scenarios. It can adapt to feeding needs of different scales without discharging in batches. Meanwhile, the hopper inner lining can be optional 6mm hardened steel or 15mm ULF wear-resistant material. For the wear characteristics of high-strength materials, its service life is 3 times longer than that of ordinary carbon steel linings.

Adaptable to Multiple Sites

The equipment provides two installation methods: the "fixed sliding frame chassis" is suitable for long-term fixed scenarios such as port terminals and mine fixed operation areas, and can achieve permanent stable operation after being fixed with bolts; the "height-adjustable wheeled chassis" is designed for phased operations and temporary material transfer scenarios. It can quickly adjust the equipment position through wheeled movement without re-pouring the foundation, and the installation and commissioning time is shortened to within 24 hours, adapting to the site planning needs of different scenarios.

Technical Parameters

| Core Parameters | Specification Range | Remarks (Based on Industry General Standards) |

|---|---|---|

| Hopper Capacity (Horizontal Stacking) | 5-15 m³ | Supports installation of 500-900mm hopper opening extension accessories, increasing the stacked capacity by 20%-30% |

| Maximum Handling Capacity | 1000 TPH (Tons Per Hour) | Optimized for aggregates, ores and other materials; the handling capacity for biomass materials can be adjusted on demand |

| Adaptable Feeding Particle Size | ≤200 mm (Millimeters) | Customizable 300mm large particle size version, suitable for mine coarse aggregate handling scenarios |

| Feeder Belt Specification | 1200mm Wide, EP 500 Type, 3-Layer | Adopts 5mm base belt + 1.5mm wear-resistant layer structure, with tear-resistant and wear-resistant properties |

| Drive Method | Single/Dual motor Direct Drive (Electric/Hydraulic) | Hydraulic drive is suitable for temporary operation scenarios without external power supply |

| Installation Method | Fixed Sliding Frame / Height-Adjustable Wheeled Chassis | The wheeled chassis is equipped with a braking system to ensure stable operation after movement |

| Applicable Materials | Aggregates, Ores, Sand, Cement Clinker, Coal | Not recommended for high-viscosity materials (such as wet clay) to avoid equipment blockage |

| Protection Level | IP65 (Electrical Control Part) | Suitable for harsh operating environments such as high humidity in ports and high dust in quarries |

Note: The above parameters can be customized and adjusted according to the customer's actual needs (such as material characteristics, site size, and back-end equipment specifications). All data have passed ZOOMRY's laboratory simulation tests and on-site verification, and comply with the ISO 9001 quality management system standards.

Product Structure Design

The structural design of ZOOMRY Static Hopper Feeder is optimized around three dimensions: "ease of use, durability, and compatibility", ensuring stable operation of the equipment under different working conditions:

Low Loss of Static Feeding System

The core static feeding system adopts a "motor-reducer-drive drum" direct connection structure, with no redundant transmission links, and the power loss is reduced to less than 5%. At the same time, it is equipped with a variable frequency drive (VSD), which can adjust the feeding speed through the control panel or remote system. For example, in aggregate classification operations, the speed can be adjusted according to the capacity of the screening equipment to avoid blockage; in ore transfer, it can synchronously follow the speed of back-end equipment to achieve "dynamic matching".

The feeder belt is an EP 500 type 3-layer wear-resistant belt, with a tensile strength of 500 N/mm, and good oil resistance and weather resistance. It can be used normally in environments from -20℃ to 60℃. The height-adjustable side skirts on both sides of the belt can effectively prevent material scattering and reduce on-site cleaning workload.

Anti-Blockage and Safe Hopper Structure

The hopper adopts a "U-shaped bottom + wide feed inlet" design: the U-shaped bottom can avoid material accumulation in corners, reducing the risk of blockage; the feed inlet width is 2.5-4 meters (adapted to capacity), which can fully cover the discharge range of wheel loaders and grab cranes, without frequent adjustment of equipment position. In addition, the bottom of the hopper is equipped with a "bolt-fixed anti-fall system", which can prevent material blocks from damaging the feeding belt and further improve the operational safety of the equipment.

Multi-Equipment Linkage Compatibility

As the core equipment of the bulk material handling line, the Static Hopper Feeder can be seamlessly linked with ZOOMRY's full range of bulk material conveying equipment: when linked with belt conveyors, the discharge port is directly connected to the feed port of the belt conveyor, and the "feeding-conveying" synchronous start and stop are realized through communication interlocking to avoid material accumulation; when linked with telescopic stackers, the feeding speed can be adjusted according to the stacking radius of the telescopic stacker to ensure uniform material piles and maximize the use of space; when linked with truck unloaders, it can smoothly convey materials to reduce the impact on the unloader and extend the service life of the equipment.

Why Choose ZOOMRY

High Customized Adaptation Capability

Most static hopper feeders of international brands are standardized products, with limited adjustment space for parameters such as hopper capacity and belt specifications. ZOOMRY can flexibly customize configurations such as hopper capacity (5-15 m³), inner lining material (ordinary carbon steel, hardened steel, ULF), and drive method (electric, hydraulic) according to the customer's material characteristics (such as high-wear ores, viscous sand), front-end feeding equipment specifications, and installation site size, ensuring the equipment is fully adapted to actual operational needs.

Full-Chain Equipment Compatibility Advantage

ZOOMRY has a full range of bulk material conveying equipment including belt conveyors, telescopic stackers, and mobile ship loaders. The Static Hopper Feeder reserves linkage interfaces with the full range of products during the design stage, enabling seamless connection without additional customized adapter components. Compared with international brand equipment, it can avoid efficiency loss and cost increase caused by cross-brand matching, ensuring the smoothness of the overall operation process.

Efficient Service Response System

Relying on a complete domestic supply chain system, ZOOMRY's equipment has more competitive prices. At the same time, it has established a spare parts supply network covering major global markets - through cooperation with local logistics providers, it can realize spare parts delivery within 72 hours (for major customers in Asia, Europe, and the Americas). The technical team provides 24-hour remote fault diagnosis services, which can quickly locate and solve equipment problems, minimizing downtime and ensuring long-term stable operation.

Full-Process Customer Support Services

ZOOMRY takes "customer needs as the core" and provides global customers with full-process services from selection to after-sales, ensuring stable operation of the equipment through an efficient system:

Free Customized Selection and Planning

After the customer provides the operation scenario (such as quarry/port), material characteristics (such as aggregate/ore), and handling capacity requirements (such as 500/1000 TPH), the technical team will output a customized selection plan including hopper capacity, installation method, and drive options through "material simulation test + site layout analysis", avoiding efficiency waste or cost increase caused by improper selection.

Professional Installation Guidance and Training

A detailed installation manual is attached when the equipment is shipped, and the technical team can provide remote installation guidance; if the customer needs, engineers can be dispatched to the site to assist in installation and commissioning (domestic customers arrive within 24 hours, international customers arrive within 72 hours according to flight arrangements). At the same time, equipment operation and daily maintenance training are provided for operators to ensure that they can proficiently master the use skills and reduce failures caused by operational errors.

Efficient Spare Parts Supply and After-Sales Service

ZOOMRY has a large-scale spare parts warehouse in China, with sufficient inventory of common spare parts such as belts, drive motors, and linings; for international customers, the "spare parts pre-positioned warehouses" model ensures delivery within 72 hours. When the equipment fails, the technical team responds within 24 hours and prioritizes solving the problem through video calls and remote diagnosis; if on-site maintenance is required, engineers will arrive at the site as soon as possible to minimize equipment downtime.

ZOOMRY

ZOOMRY