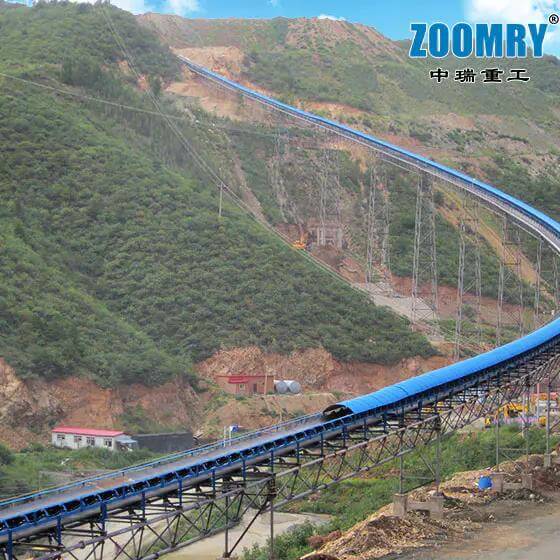

Zoomry Portable stacker is specially designed for farm storage, sand-gravel transfer, and construction sites. Integrating a reinforced chassis with patented folding arm technology, it achieves rapid deployment in 3 minutes, overcomes 30° slope limitations, and delivers a single-meter payload of 2 tons while boosting operational efficiency by over 200%!

Features of Portable Stacker

Terrain-Adaptive Platform

Computer-optimized box-beam chassis with optional track/tire drive systems, certified for 30° extreme slopes. Low center-of-gravity anti-tip structure ensures stable operation in complex terrains like mines and quarries.

Multi-Joint Folding Technology

Hydraulic multi-section folding mechanism enables rapid configuration switching: Transport length ≤12m for road compliance; Operational extension 15-30m (customizable). Integrated dynamic balancing system maintains operation plane precision within ±1°, improving site adaptability by 40%.

High-Efficiency Feed Integration

0.8m ultra-low receiving hopper interfaces directly with various construction machinery. Three-directional dust suppression panels reduce material spillage by 18%. Streamlined design optimized for efficient transfer in confined spaces.

Dual-Power Configuration

Zoomry Portable Stacker diesel version features high-efficiency engines for continuous field operations; Electric version compatible with 380V industrial power, reducing energy consumption by 35% compared to traditional equipment. Both power modes CE safety certified.

Intelligent Conveyance Control

1.0-3.0m/s infinitely variable speed belt coupled with hydraulic pitch mechanism (-5°~+25°), supporting 200m wireless remote operation. Equipped with cascade control interface for multi-unit coordination.

Long-Term Protection System

Portable Stacker components achieve IP65 protection rating with wear-resistant steel plates ensuring durability in harsh conditions. Triple-layer anti-corrosion coating withstands humid/salty environments. Reinforced chassis design adapts to most terrain conditions.

Scenario-Specific Solutions

Farm Grain Transfer

- Suitable Materials: Rice, soybeans, animal feed

- Technical Requirements: Continuous conveyance at 15° slopes in hilly areas, requires rainproof and contamination-proof design

Building Material Storage Logistics

- Suitable Materials: Cement prefabs, steel products

- Technical Requirements: 6-8m precise stacking with dust-sealing and anti-collision protection

Sand-Gravel Aggregate Conveyance

- Suitable Materials: Granite, manufactured sand, limestone

- Technical Requirements: 300-550 t/h throughput capacity, wear/impact resistant structure

Construction Waste Handling

- Suitable Materials: Concrete fragments, metal scraps

- Technical Requirements: Corrosion-proof and anti-tangling design, supports 30° slope operations

Technical Parameters

| Model | Capacity (t/h) | Working Span (m) | Drive Power (kW) | Traverse Power (kW) | Gradeability | Stacking Height (m) |

|---|---|---|---|---|---|---|

| ZR65D | 200 | 15/20/25 | 18.5 | 11 | 18° | 6.5/8.0 |

| ZR80D | 300 | 15/20/25 | 22 | 11 | 18° | 6.5/8.0 |

| ZR100D | 400 | 15/20/25 | 30 | 15 | 18° | 6.5/8.0 |

| ZR120D | 550 | 15/20/25 | 37 | 15 | 18° | 6.5/8.0 |

Core Technology Notes:

- Belt speed continuously adjustable between 1.0-3.0m/s

- Portable Stacker track version compatible with 30° enhanced climb kit

- Full series compliant with CE certification standards

Why Choose Zoomry

Military-Grade Manufacturing Standards

Combines special steel with precision welding techniques, 100% non-destructive testing on critical welds. Engineering team provides scenario-specific customization solutions.

Full-Cycle Service Network

| Service Module | Time Commitment |

|---|---|

| Solution Design | 24hr Technical Configuration |

| Installation Guidance | On-site Professional Engineers |

| Equipment Delivery | Standardized Production Schedule |

| Fault Response | 48hr Emergency Support Channel |

Extended Warranty System

Core components backed by 5-year extended warranty including smart maintenance reminders and operator training. Quality commitment covers equipment lifecycle, building sustainable partnership ecosystem.

ZOOMRY

ZOOMRY